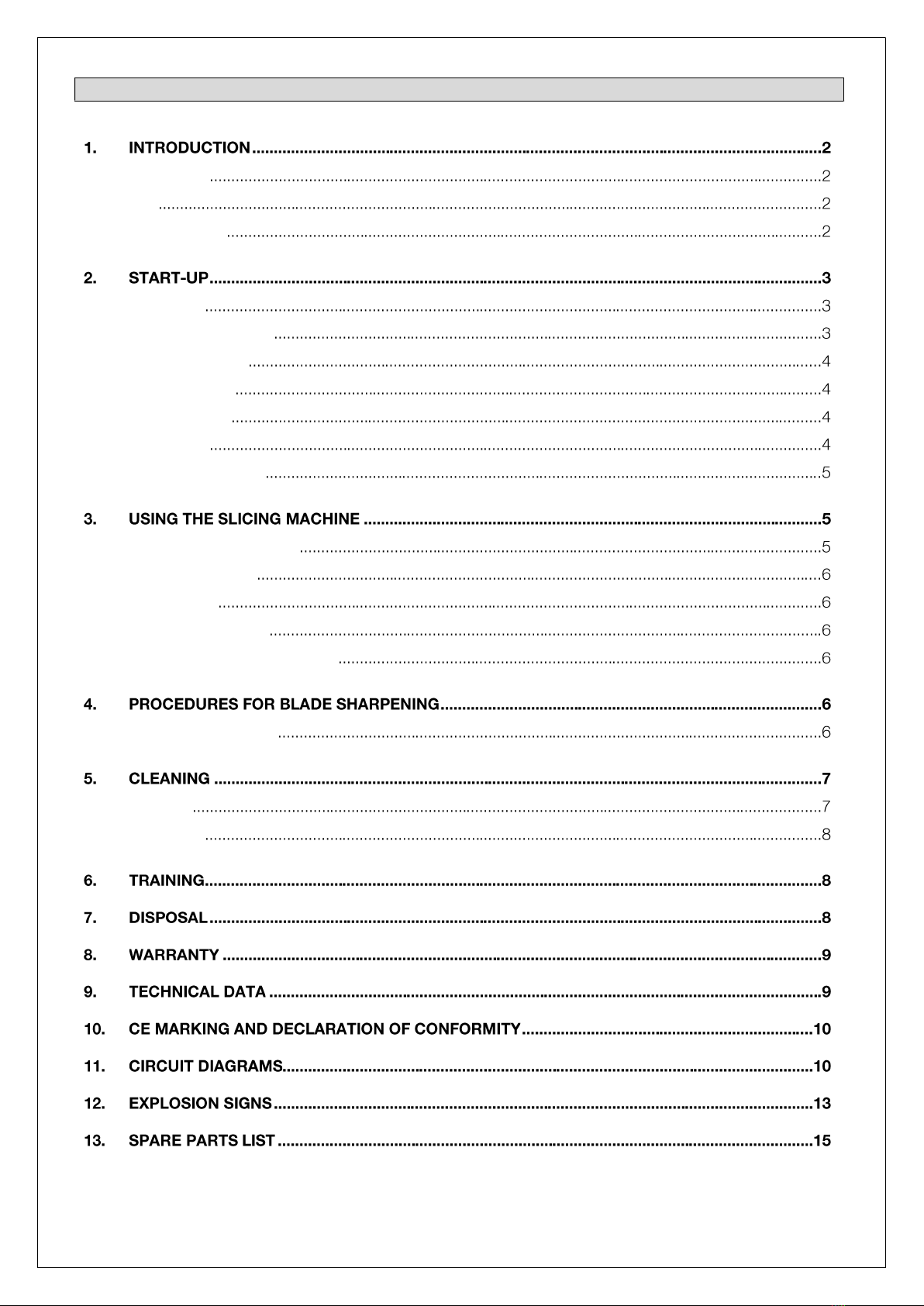

1. INTRODUCTION

This manual has been written in accordance with the specifications of the Machinery Directive as amended.

Thus, the manufacturer wants to inform the customer about the basic operating principles, maintenance

requirements and safety devices of the machine in a clear and easily understandable form to ensure a long

service life and reliable operation of the machine.

The slicing machines are subject to continuous improvements, but this does not affect the instructions and

information given in this manual.

Read this manual carefully before operating the slicing machine.

If this manual becomes worn out or gets lost over time, immediately request a copy of the manual from the

manufacturer.

The majority of accidents and injuries that occur when using the machine is due to insufficient knowledge of

its functions and safety devices. Therefore, the instructions and information contained in this manual should

be read carefully before starting work with the machine.

1.1 Introduction

The slicing machines are designed according to applicable safety standards. For this reason, you will find the

“CE” label on each of our slicing machines, which certifies compliance with the above-mentioned

requirements.

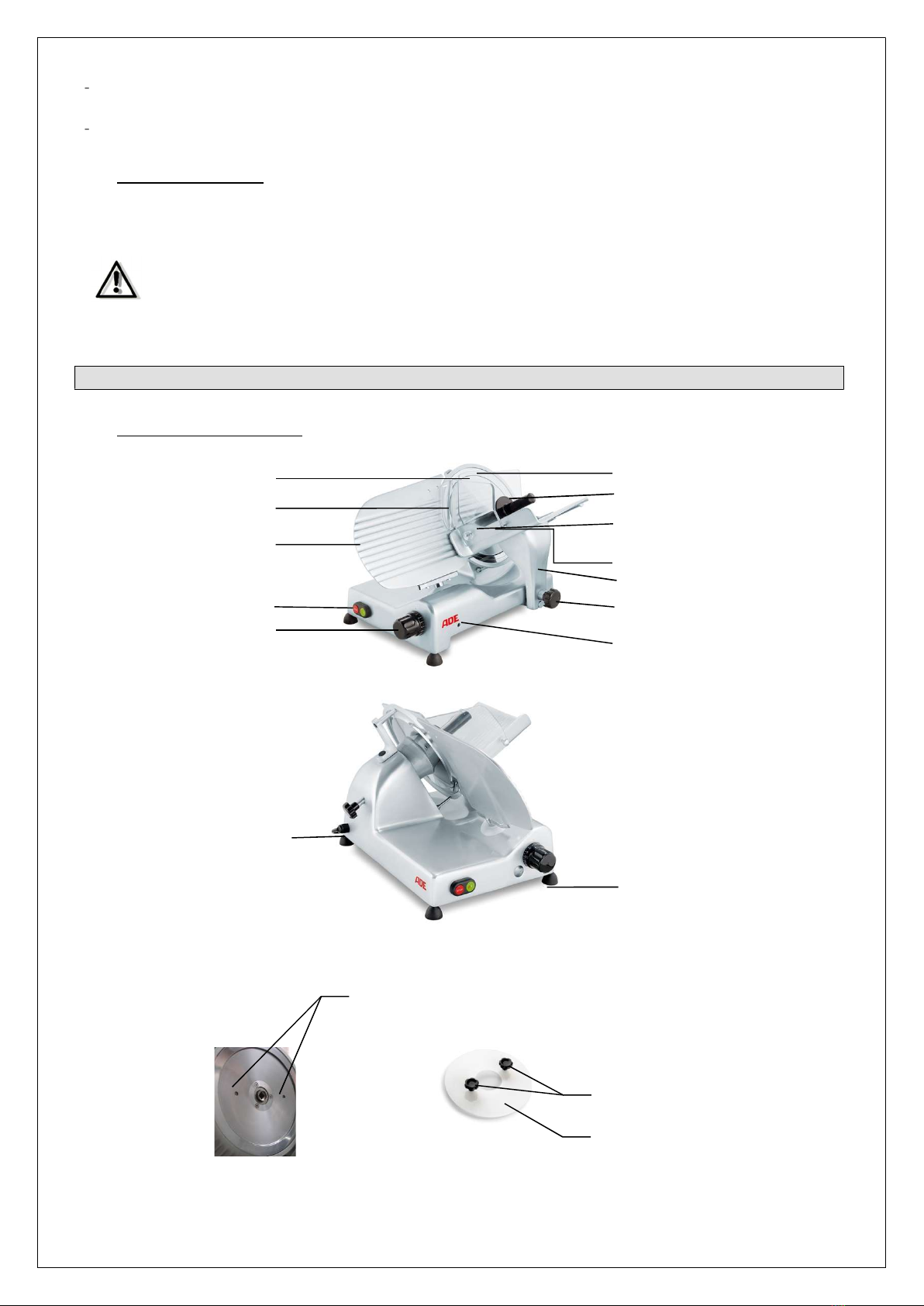

The housing as well as carriage, feed plate and blade protection sickle are made of anodised aluminium. This

allows for easy cleaning. The blade drive is ensured by a motor with V-belt drive with a noise level of <70dB

measured at a distance of 1 metre at the height of 1.60 metres.

The total vibration of parts coming into contact with hand and arm is <2.5m/s².

1.2 Use

This slicing machine is used for slicing cooked and raw sausages, hot or cold meat, cheese and bread

depending on the blades used. By default, the machine is equipped with a smooth blade. It is recommended

to cut cheese using a Teflon coated blade as well as a temperature of the product being cut of 7-10°C. For

cutting bread, optional long-toothed blades with and without Teflon coating are available. The machine is not

suitable for cutting some types of hard cheese and bread. A cutting thickness up to 15 mm can be set.

Under no circumstances may the slicing machine be used for slicing frozen products,

meat or sausage products with bone, fruit and vegetables or non-food products.

Failure to observe these instructions can seriously damage the machine and, where

applicable, void existing warranty claims.

The machine is suitable for catering approx. 60 persons (Victoria 250) or approx. 100 persons (Victoria 275

and Victoria 300). These values are merely recommendations that are based on empirical values and can

differ depending on the application. The maximum switch-on duration is 40% (based on 1 hour = 24minutes).

Thereafter, a corresponding cooling time for the motor must be taken into account. At shorter switch-on

times, the cooling intervals are also correspondingly shorter.

The machine may only be used in its original condition and with original parts. Disassembling the protective

equipment is not allowed. In case of damage to protective equipment, the machine must be immediately put

out of operation and ADE must be informed for the purpose of renewal or replacement.

1.3 Residual risks

Despite extensive safety precautions on the machine, residual risks remain for the operator in the daily work

with the machine. These occur in particular when the operator tries to push the product being cut by hand to

the blade. The built-in leftover holder must always be used to feed the product. During the cutting process,

the operator's hands must not be in the carriage area.