Prosciutto300-191107-Rev006-UM-en 2

1. INTRODUCTION

1.1 Purpose of the manual

This publication contains all the information necessary for the installation, use and maintenance of the

manual flywheel slicing machines to be used for food, with circular blade.

The purpose of this manual is to allow the user, above all the direct user, to take every precaution and

arrange all human and material means necessary for a safe and lengthy use of these machines.

The slicing machines are subject to continuous improvements, which do not restrain the current instructions

in this handbook.

This manual must be given to the person who will use and maintain the machines and this person will keep

the manual in a safe and dry place, ready to be used. We recommend that a copy is being kept on file.

The manual must be kept for the entire life of the machine and in case of need (ex. any damage to even a

part of the manual that makes consulting it difficult) the user must acquire a new copy exclusively from the

manufacturer. The user must let the manufacturer know the address of any new owner of the machine.

For any correspondence with the manufacturer or authorized personnel, please refer to the information on

the plate and the machine serial number.

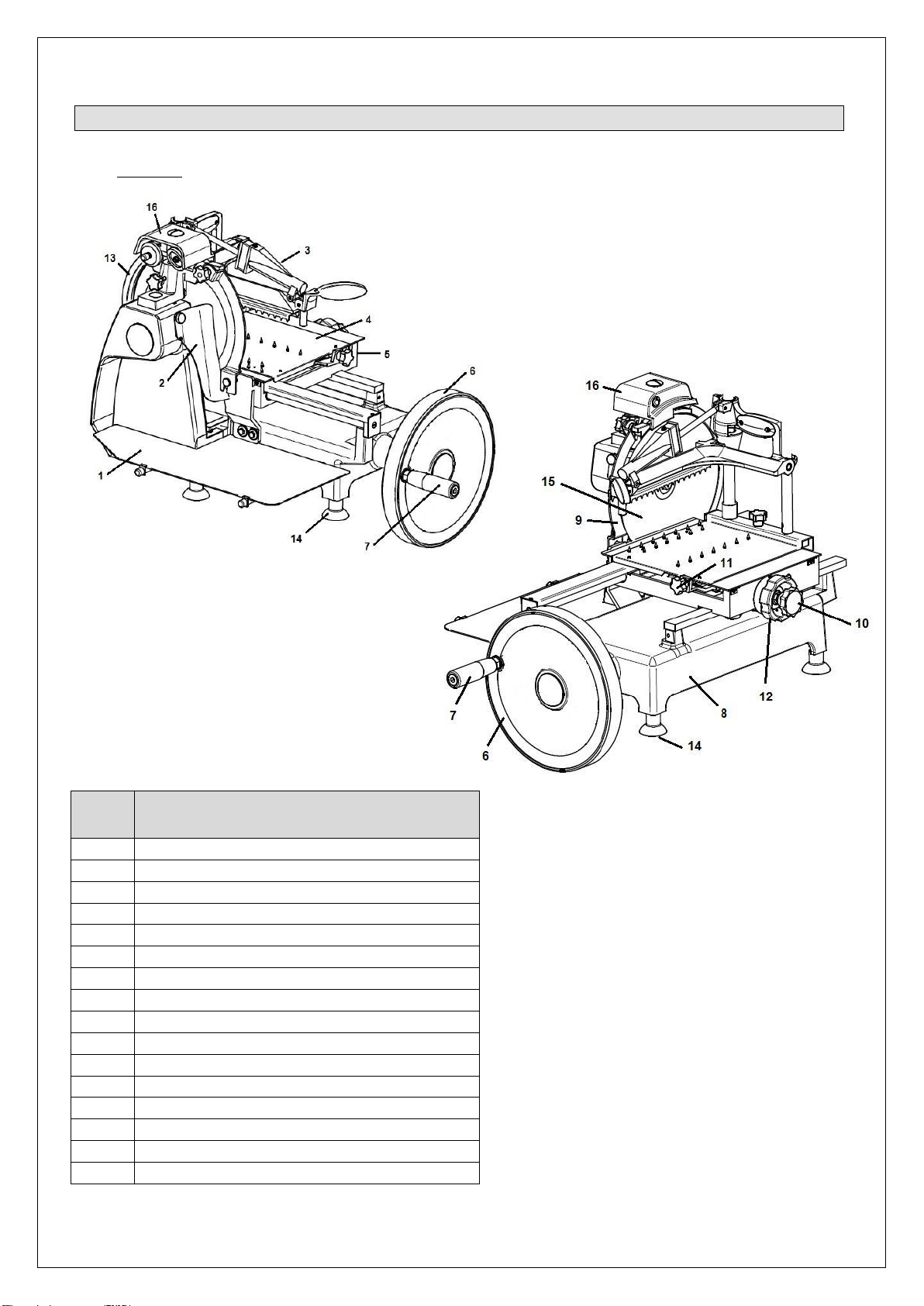

1.2 General description of the machine

The slicing machine has been designed and made to offer maximum safety when in use, during cleaning and

ordinary maintenance; maximum hygiene from the use of inoxidisable materials or adequately protected

against oxidation together with an attentive design of all the parts that come into contact with food;

maximum cutting precision and capacity together with sturdiness and reliability of the structure.

The machine is essentially made up of a base that holds a circular blade that is vertically mounted and a

sliding carriage on bars, parallel to the cutting edge of the blade, which in turn holds a food plate.

The food plate is made up of a base plate and an overplate which slides at right angles to the edge of the

blade for slicing the food; the overplate also has an appropriate self-stopping device, which can be

regulated in height, to keep the product in its proper place during cutting operations (food press).

Carriage movement and blade rotation are completely manual; by activating rotation of the flywheel with

the special handle, the carriage is put into motion and the blade is turns at the same time with a chain

transmission.

The product is cut during the forward movement of the carriage, parallel to the blade; the thickness of the

slice is regulated by a mechanical device which is automatically started every time the carriage comes back,

making the sliding overplate transversally towards the blade, with a value which is pre-determined by the

graduated handwheel.

All the components of the machine are made of a light aluminium alloy, in stainless steel and plastic for food

products as according to the sanitary regulations in force.

The machine has a sharpener which is extremely easy and safe to use. The food plate, sharpener and blade

cover can be removed for cleaning.