33

The following tools (not included) are needed for making adjustments:

1

7

8

9

10

11

13

12

14

15

16

1718

19

20

21

22

31

24

25

26

28 29

27

COMBINATION SQUARECOMBINATION WRENCHFRAMING SQUARE HEX KEY

3MM

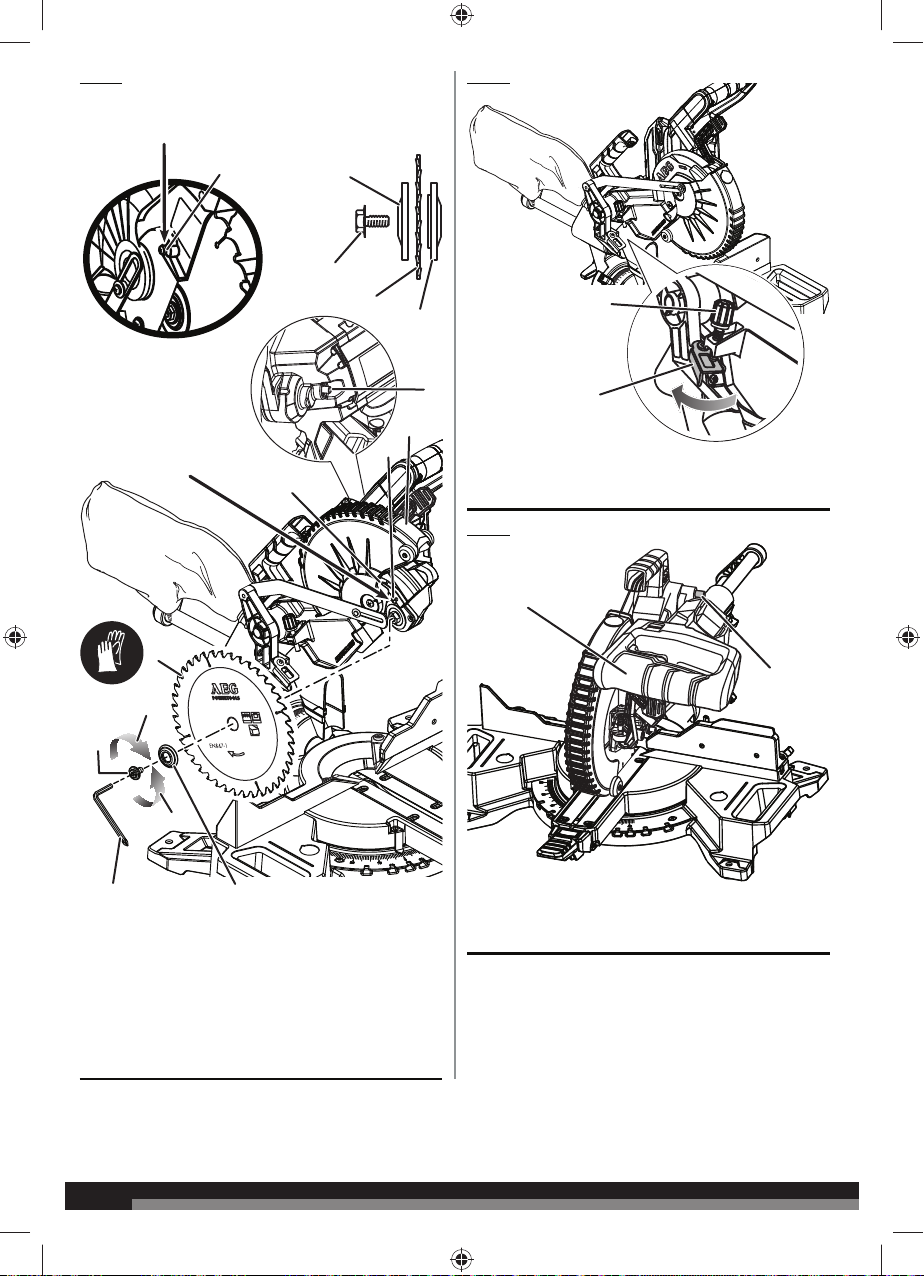

1 - “D” Handle

2 - Head lock pin

3 - Blade wrench storage

4 - Single/dual bevel selector

5 - Bevel lock knob

6 - Sliding fence adjustment knob

7 - Switch trigger

8 - Lower guard lock out lever

9 - Upper blade guard

10 - Lower blade guard

11 - Sliding fence

12 - Work clamp

13 - Lift handle

14 - “No hands zone” boundary line

15 - “No hands zone” label

16 - Mitre detent release button

17 - Mitre lock lever

18 - Control arm

19 - Throat plates

20 - Mitre scale/ Mitre scale detent plate

21 - Turning table

22 - Saw base

23 - Bevel stop turret

24 - Fixed fence

25 - Depth stop

26 - Slide bar

27 - Dust bag

28 - Carrying handle

29 - Depth control knob

30 - LED light button

31 - Fence extension

32 - Spindle lock button

33 - Saw blade

34 - Mounting holes

35 - Bevel scale

36 - Screws for adjusting mitre angle

37 - Bevel stop adjustment screw

38 - Sliding lock knob

30

32

2

645

23

3

23

34

36

34

13

34

35

37

33

Ø 184 mm

n

max.

7900

Ø 20 mm

40HW 1.6mm

38