7

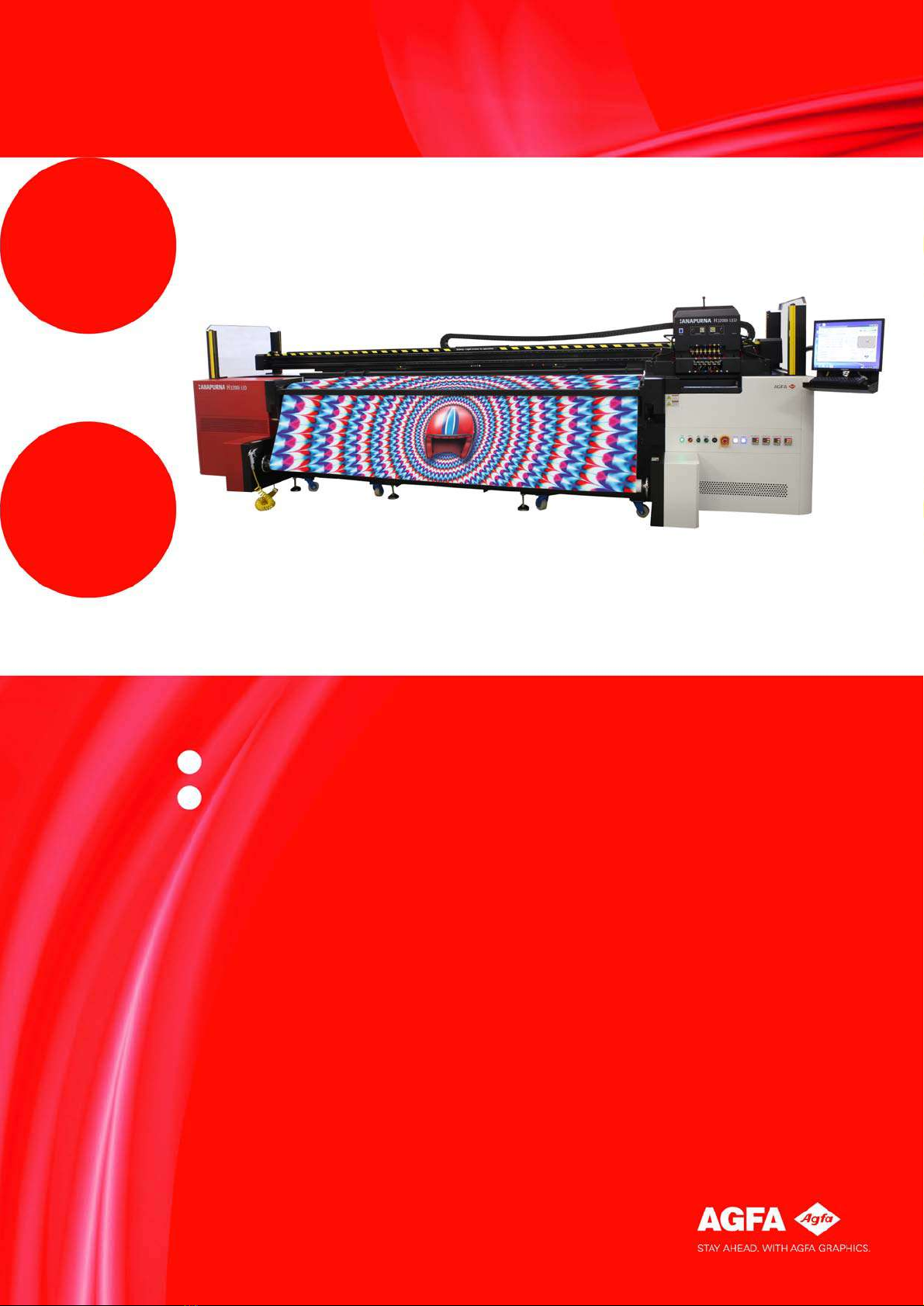

:Anapurna H3200i LED Advanced Operator Manual (v1.0)

Automatic Tension Compensation ........................................................................ 61

Using the Tension Compensation..................................................................... 62

Tips and tricks ...................................................................................................... 64

Chapter 7 Image quality procedures ............................................................................................. 67

Setting the Head Gap............................................................................................... 67

Head Gap Procedures.......................................................................................... 67

Automatic Head Gap setting ............................................................................. 67

Setting Media Thickness Manually .................................................................. 68

Checking and clearing inkjet nozzles................................................................... 69

Prime (nozzle) check print................................................................................. 69

Dripping the Heads.............................................................................................. 71

Purging the print heads with ink...................................................................... 72

Checking and draining color heads ....................................................................... 73

Checking an Ink Circuit for Air.......................................................................... 73

Draining a color head.......................................................................................... 74

Image Quality levels ................................................................................................ 76

High Definition Quality....................................................................................... 76

High Quality.......................................................................................................... 76

Standard Quality .................................................................................................. 76

Production Quality............................................................................................... 76

Express Quality..................................................................................................... 76

Draft ....................................................................................................................... 76

Calibration.................................................................................................................. 77

Ink dot placement ............................................................................................... 77

Calibration............................................................................................................. 77

Calibration zone................................................................................................... 78

Horizontal Calibration......................................................................................... 78

Bidirectional Calibration .................................................................................... 81

Feed calibration ................................................................................................... 84

White ink circuit ....................................................................................................... 87

Automatic filling of the white ink circuit with storage flush or ink.......... 87

Improved auditive alarm indication................................................................. 88

Improved visual alarm indication..................................................................... 89

Alarm warning...................................................................................................... 90

Activate the alarm reading ................................................................................ 90

Alarm indications and meaning........................................................................ 91

Purge time limitation.......................................................................................... 92

Vacuum switch off signal................................................................................... 92

Chapter 8 Printing............................................................................................................................. 93

Configurations overview.......................................................................................... 94

Chapter 9 Curing procedure ............................................................................................................ 95

Set UV light intensity............................................................................................... 95

UV Controls in the Printing Panel ......................................................................... 96

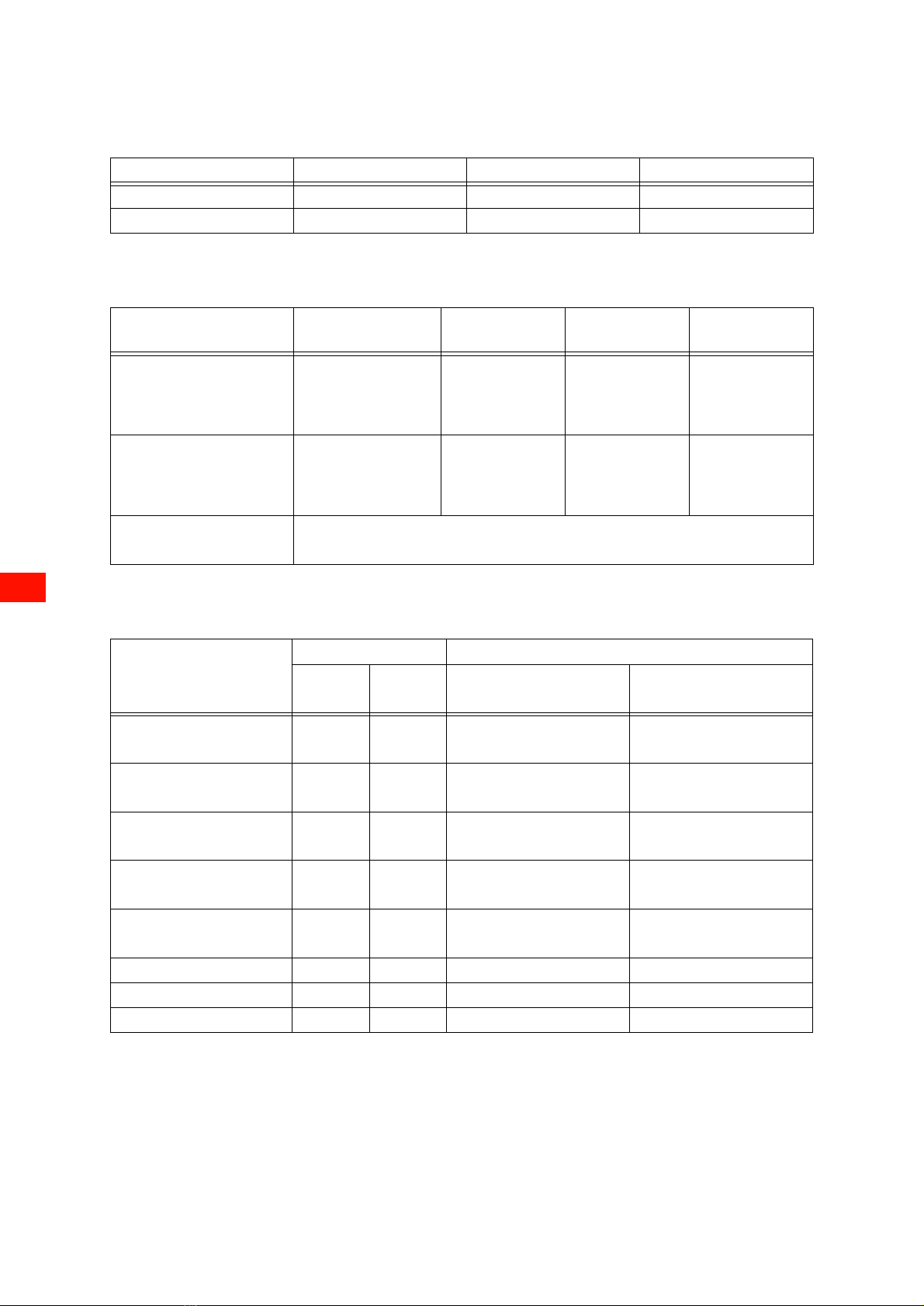

LED Combinations of the UV Modes................................................................ 96

Chapter 10 Maintenance procedure .............................................................................................. 101

Maintenance Schedule .......................................................................................... 101

Daily Maintenance ............................................................................................101

Weekly Maintenance........................................................................................101

Monthly Maintenance.......................................................................................101