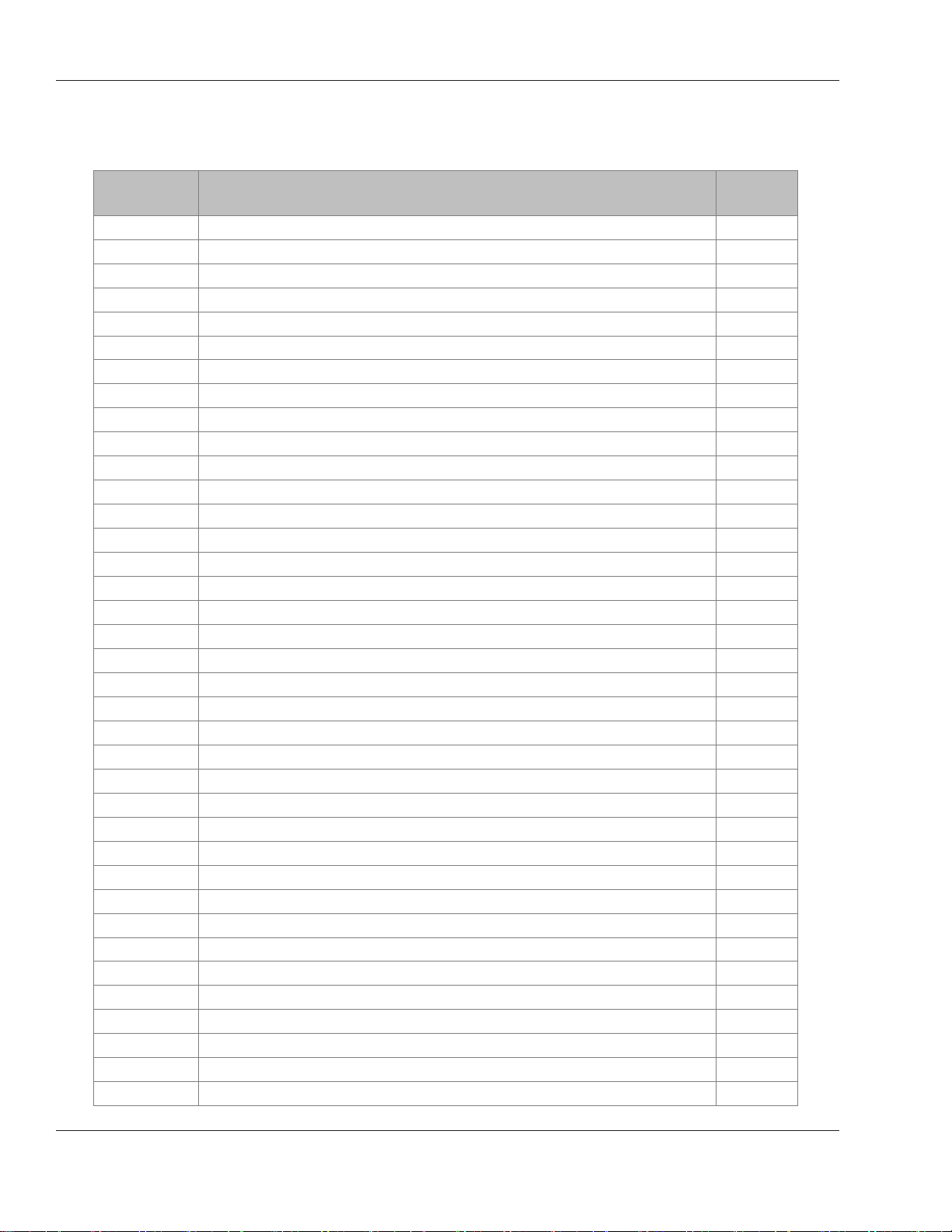

4. Off-Loading Conveyor System.............53

Before Using the OCS...................................54

Conveyor Safety............................................ 54

Using the Conveyor....................................... 56

Charging the OCS Hydraulics....................... 56

Conveyor Tracking........................................ 57

Conveyor Maintenance................................. 58

Using the Basket ..........................................59

Basket Maintenance.....................................61

Basket Covers..............................................62

Basket Safety Strut.......................................62

Troubleshooting............................................63

5. Controls and Adjustments....................65

Overview.......................................................67

Control and Adjustments..............................68

Adjustable Overhead Teeth..........................68

Retention Board Adjustment.........................69

CleaningAir Control......................................70

Tailboard Adjustment....................................71

ElevatorAir Control......................................72

Standard Pickup Header Speed Control.....73

Remote Auger Reverse...............................73

PTO Speed Adjustment...............................74

Pickup Header Height Adjustment ..............76

HeaderAugerAdjustment............................77

Rotor SpeedAdjustment..............................78

Variable Pitch Vine Spreaders.....................78

6. Performance.........................................81

Fine Tuning Operation..................................83

Achieving Maximum Ground Speed.............83

Increasing Picking Capacity..........................84

Harvesting Under Wet Conditions................85

Troubleshooting............................................86

Table of Contents (cont.)

7. Maintenance ...................................... 91

Belt Adjustment ......................................... 93

Chain Adjustment ...................................... 94

Lubrication ................................................ 95

PTO and Driveline ..................................... 96

Schedule & Lubricants .............................. 97

Lubrication Locations.................................98

Post Season Maintenance..........................99

Tire & Wheel Fasteners Torque.................100

8. “Peanut Tech”Monitoring and Control..........103

Key Features............................................104

Home Screen Functions and Controls.....106

Help/Basic Instruction Screens................107

Access Setup Screen .............................107

All Information Screen...................................108

Calibrating theActuator..................................109

CustomAir Pressure Settings.......................109

Warranty......................................................116

Introduction M2120A PT Peanut Combine

11/2/18 MAN152

ii