1

Falcon IT (FIT)

Quick Installation and Adjustment Instructions

Medical Facility Responsibility

Preventive maintenance checks must be performed regularly to maintain the quality and performance of this product. Any parts that

may be broken, missing, worn, distorted, or contaminated in any way should not be used and all affected parts should be replaced

immediately. Should the necessity of any repair be suspected; please contact your local Amico distributor.

WARNING: It is the responsibility of the end user to ensure all aspects of the installation are covered by following the full

manual at: https://www.amico.com/sites/default/files/product/downloads/amico-aa-wall-mounted-computer-

workstation-falcon-manual.pdf

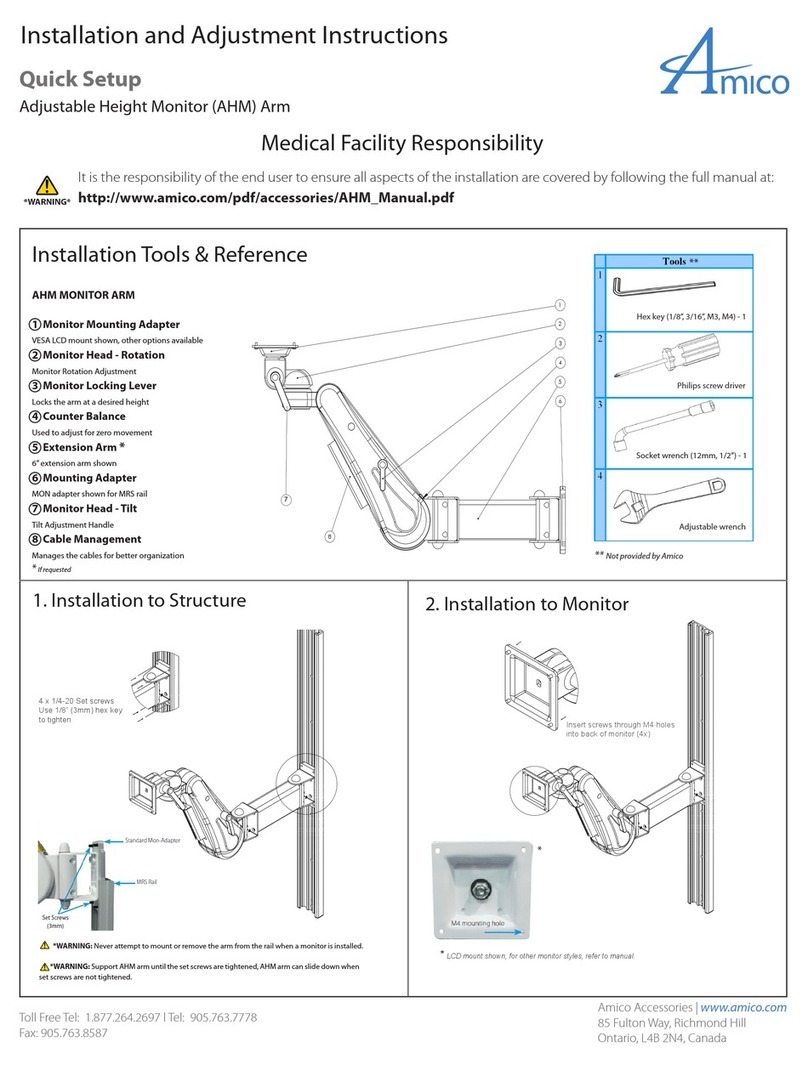

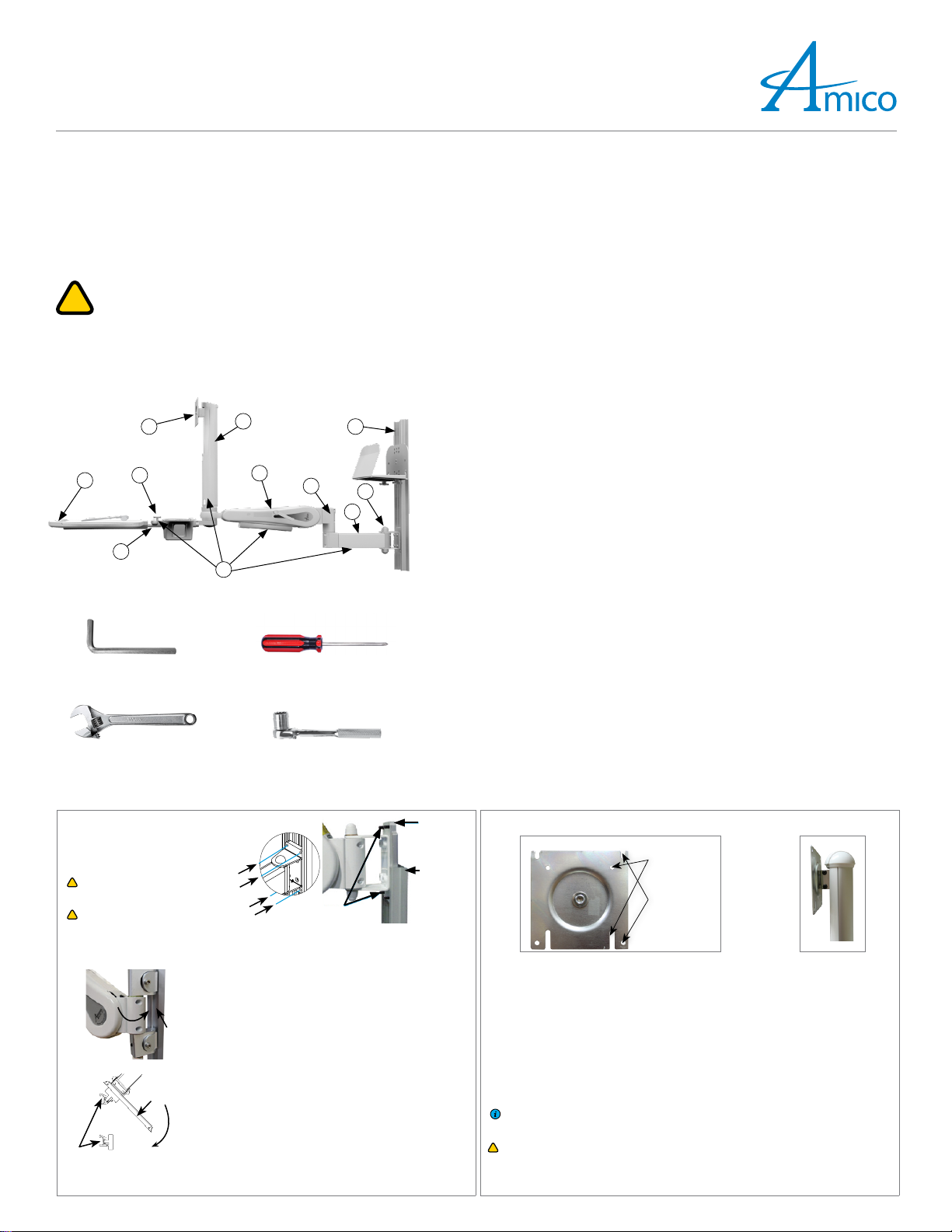

Installation Reference andTools

Hex Key (1/8", 3/16", M3, M4) #2 Phillips Head Screwdriver

AdjustableWrench SocketWrench (12 mm, 1/2")

FIT

1. Swivel Post

For mounting and positioning of monitor.

2. Extension Arm

Extension arm to increase movement range of AHM ARM (if applicable).

3. Mounting Adapter

Different mounting adapters will be provided based on the rail system used.

4. Cable Management

Manage cables for the FIT station for a clutter-free environment.

5. Height-locking Lever

Locks arm at the desired height.

6. Counter-balance Bolt

Balance the weight of the monitor on the AHM ARM of the FIT.

7. Negative Tilt Knob

Tilts the keyboard tray’s back downwards for proper ergonomics in certain cases.

8. Keyboard Tray

Locationforkeyboard& mouse. (2x mousepads, 12x duallock coins provided; wrist restif purchased).

9. Rail System

For mounting the FIT station, varies depending on user’s selection. Rail is packed separately and must

be installed first.

10.VESA Head

For mounting the monitor.

11.Mouse/Scanner Holder

For storing mouse and hand-held scanners.

1

5

3

7

10

2

6

9

4

8

11

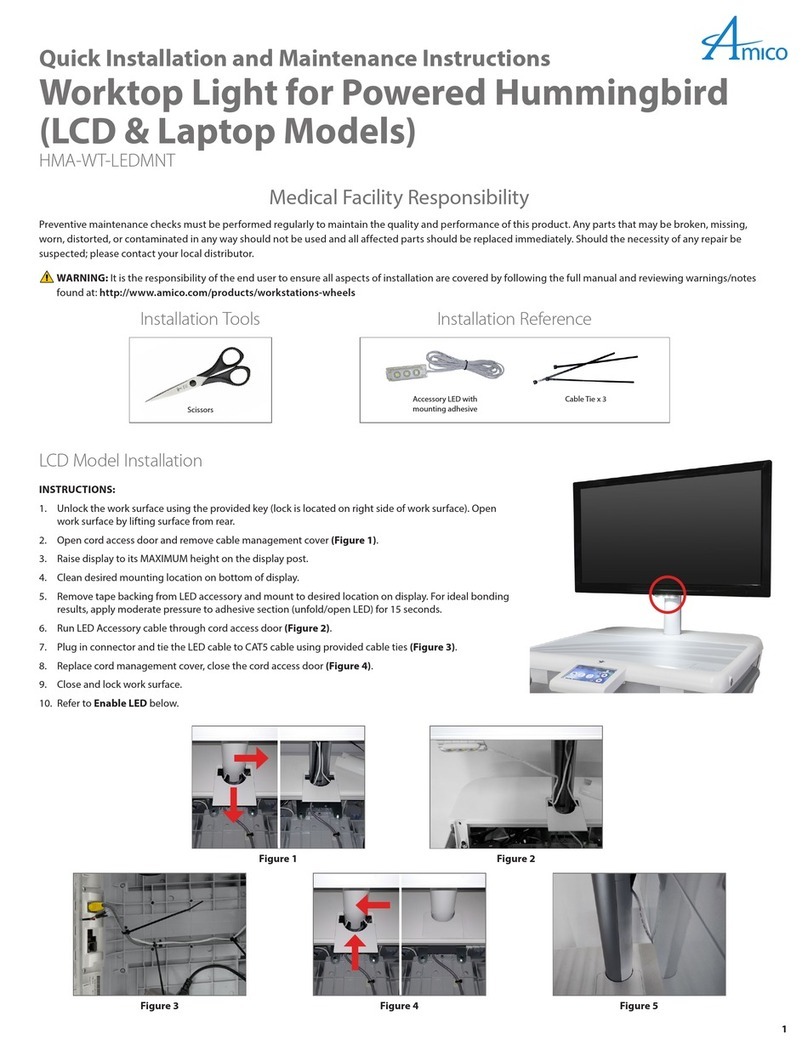

1. Installation to Structure 2. Installation to Monitor

Mounting on an MRS Rail

4x 1/4-20SET SCREWS. Use 1/8" (3 mm) Hex

Key to tighten.

WARNING: Never attempt to mount or

remove the AHMARM from the MRS RAIL

when a monitor is installed.

WARNING: Support AHM ARM until the SET

SCREWS are tightened, AHMARM can slide

down when SET SCREWS are not tightened.

VRS

RAIL

STANDARD

MONADAPTER

MRSRAIL

SETSCREWS

3 mm

ARSRAILS

MOUNTING

ADAPTER

CHANNEL

ARS

ADAPTERINSTALLED

Mounting on a VRS/Ohmeda Rail

Angle the AHM ARM from the left of the CHANNEL and guide the

ADAPTERS into the groove of the CHANNEL. Tighten SCREW with

a 3/16" Hex Key when V-ADAPTER is at the desired height. When

tightened, the SCREW will protrude from the other side. Fasten the

NUT to the SCREW to secure the V-ADAPTER. If the NUT cannot be

installed, the ADAPTER is not properly engaged. Check that all NUTS

and SCREWS are tightened to ensure the V-ADAPTER is locked.

Mounting on a Headwall

Pop out the cover from the MOUNTING ADAPTERCHANNEL to

access the SCREWS. Remove the 2x SCREWS and LOCK WASHERS to

free bottom MOUNTINGADAPTER. Install it into the bottom RAIL

by angling the upper lip into the inside lip of the ARSRAIL, pull the

lever back against the MOUNTINGADAPTER and push the ADAPTER

into the ARS RAIL. Once secure, release the lever.

Install the remaining MOUNTING ADAPTER into the top ARS RAIL

the same way as step 1, ensuring the 2xHOLES on the bottom

MOUNTING ADAPTER can be seen through the MOUNTINGADAPTER

CHANNEL. Secure the CHANNEL to the bottom MOUNTINGADAPTER

using the SCREWS and LOCKWASHERS you removed in step 1.

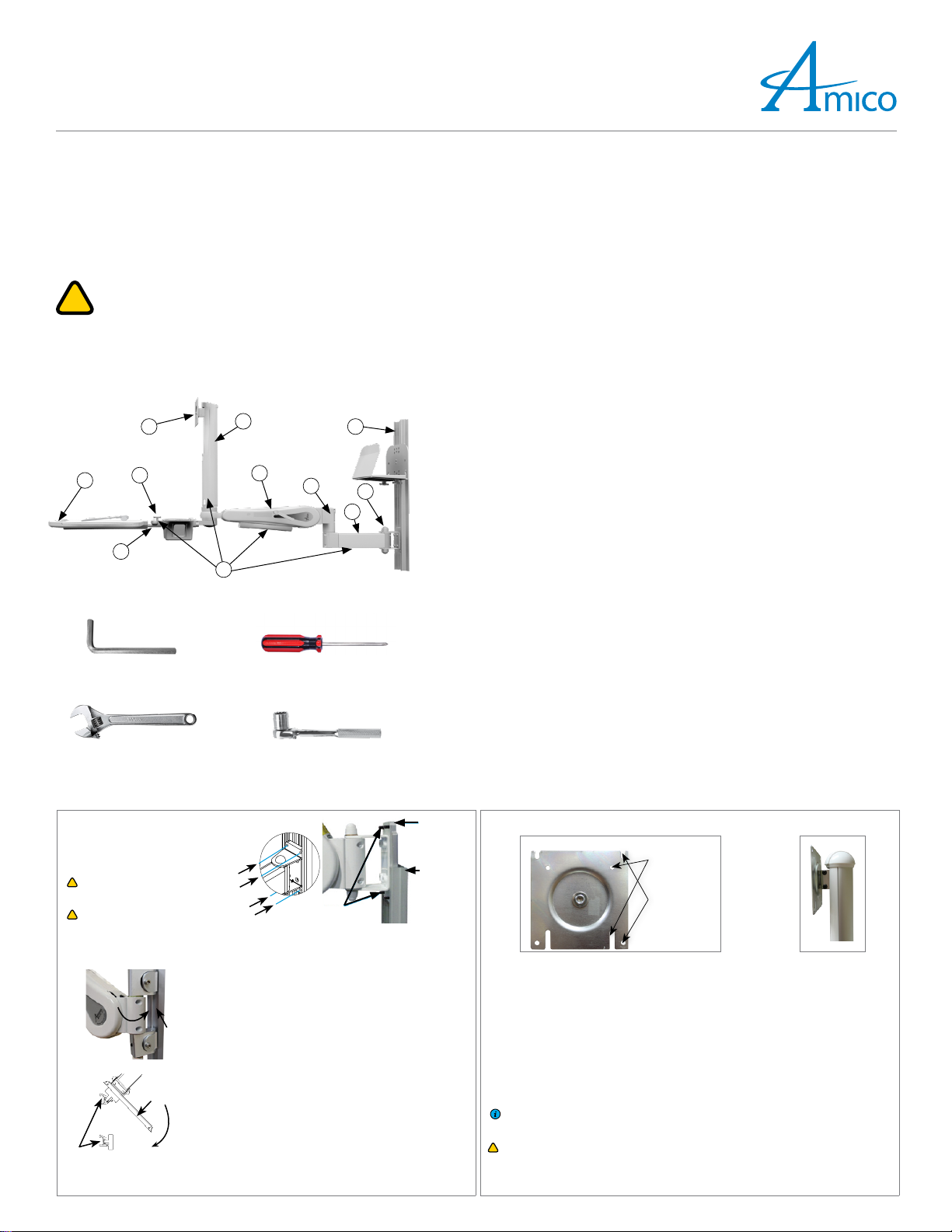

1. Determine the monitor mounting configuration. VESA75 (75 mm x 75 mm M4 thread) or VESA100

(100 mm x 100 mm M4 threads).

2. VESA 100 Configuration: 2x SCREWS are partially threaded into the top 2xHOLES in the back of the

monitor. The monitor can then be hung up on the VESAHEAD through the 2x slots at the top. Insert

2x more SCREWS through the VESA100MOUNTINGHOLESat bottom, tighten all SCREWS. (Figure 1)

3. VESA 75 Configuration: Rotate the VESAHEAD so the 2x slots for the VESA75 configuration are

located at the top. Partially thread 2x SCREWS into the top 2x HOLES in the back of the monitor.

The monitor can then be hung up on the VESAHEAD through the 2x slots at the top. Insert 2x more

SCREWS through the VESA 100 mounting holes at the bottom and tighten all SCREWS.

4. When removing the monitor, the monitor ARM and the monitor should be placed at the highest

position (Figure 2). Remove the 2x bottom SCREWS from the VESAPLATE, loosen the top 2x SCREWS,

and lift the monitor off the VESAPLATE.

NOTE: 4x M4SCREWS are provided for mounting the monitor to the VESAHEAD, different SCREWS

may be needed if the provided SCREWS are not the right size, standoffs may be needed

depending on the hole pattern on the monitor.

WARNING: Ensure that the AHM ARM is in the highest vertical position and locked before mounting

or removing devices from the FIT station.

FRONTOFTHE VESA75/100 M4MOUNTING

HOLEFORVESA75

M4MOUNTING

HOLEFOR

VESA100

Figure 1 Figure 2