Chapter 2: Installation and Removal Procedures and Notes

• Mounting Instructions

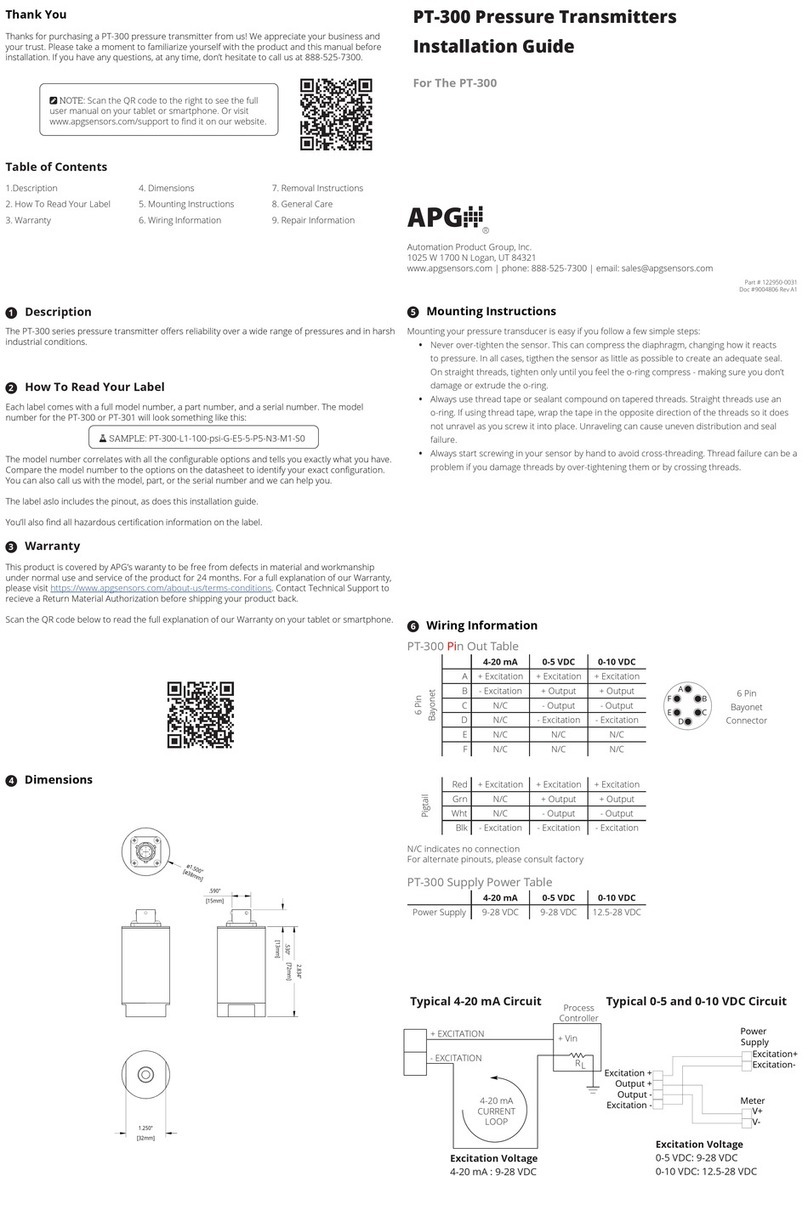

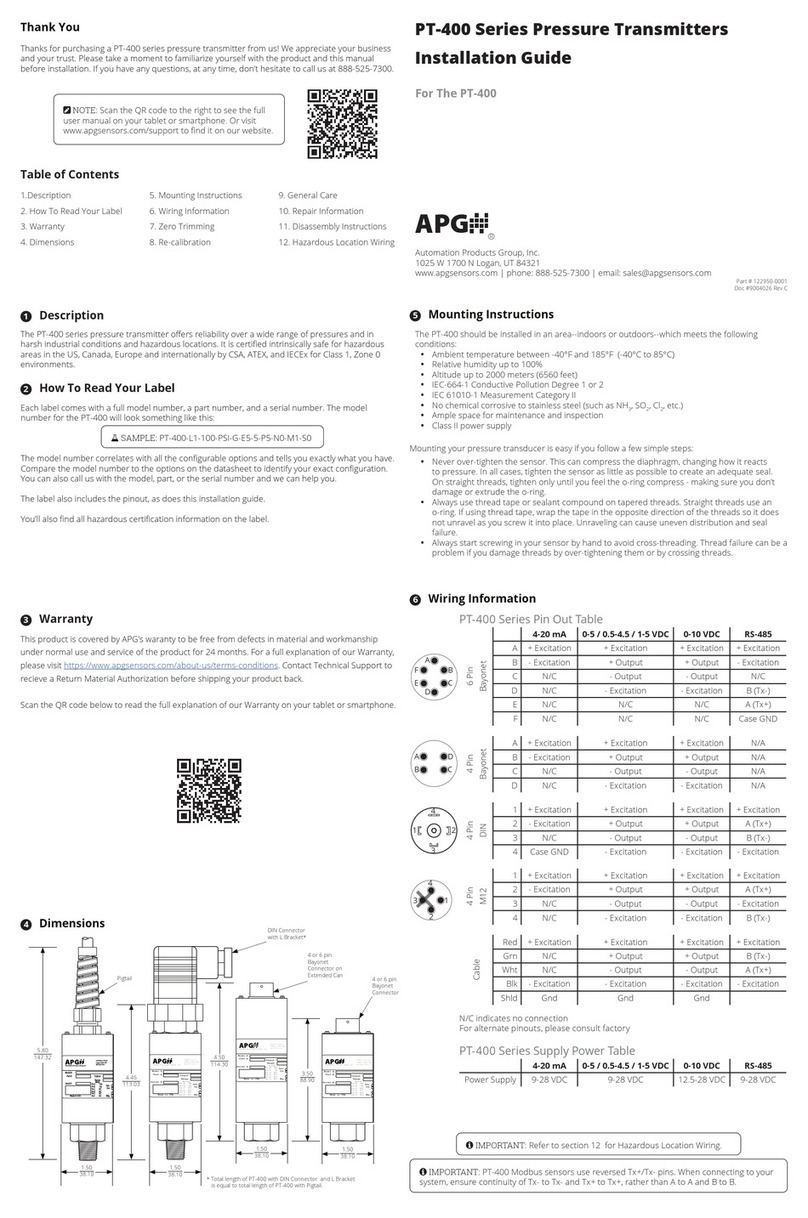

• Check the pinout table on your PT-300 against your order.

• Check that your electrical system wiring matches the pinout table on your PT-300.

• For instruments with connectors, make the connection. Otherwise, attach your wires to the provided

terminal strip.

• Electrical Installation

Removing your PT-300 from service must be done with care. It’s easy to create an unsafe situation, or

damage your sensor, if you are not careful to follow these guidelines:

• Make sure the pressure is completely removed from the line or vessel where your sensor is installed.

Follow any and all procedures for safely isolating any media contained inside the line or vessel.

• Remove the sensor with an appropriately sized wrench (per your process connection).

• Clean the sensor’s tting and diaphragm of any debris (see General Care) and inspect for damage.

• Store your sensor in a dry place, at a temperature between -17° and 70° C (0° - 158° F).

• Removal Instructions

Mounting your pressure transducer is easy if you follow a few simple steps:

• Never over-tighten the sensor. This can compress the diaphragm, changing how it reacts to pressure.

In all cases, tighten the sensor as little as possible to create an adequate seal. On straight threads,

tighten only until you feel the o-ring compress - making sure you don’t damage or extrude the o-ring.

• Always use thread tape or sealant compound on tapered threads. Wrap thread tape in the opposite

direction of the threads so it does not unravel as you screw the sensor into place. Unraveling can cause

uneven distribution and seal failure. For straight threads use an o-ring.

• Always start screwing in your sensor by hand to avoid cross-threading. Thread failure can be a problem

if you damage threads by over-tightening them or by crossing threads.

DANGER: Removing your PT-300 Pressure Transmitter while there is still pressure in

the line could result in injury or death.

• Wrench sized appropriately for your PT-300’s process connection.

• Thread tape or sealant compound for threaded connections.

• Tools Needed