*24771*

24771

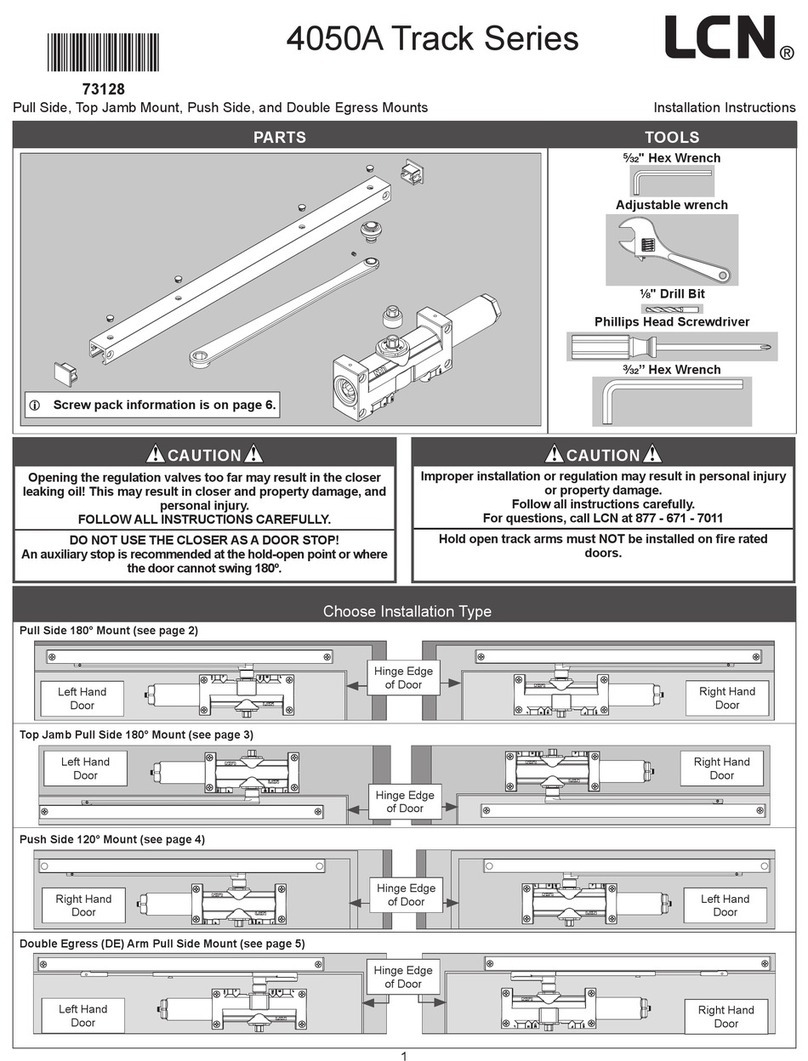

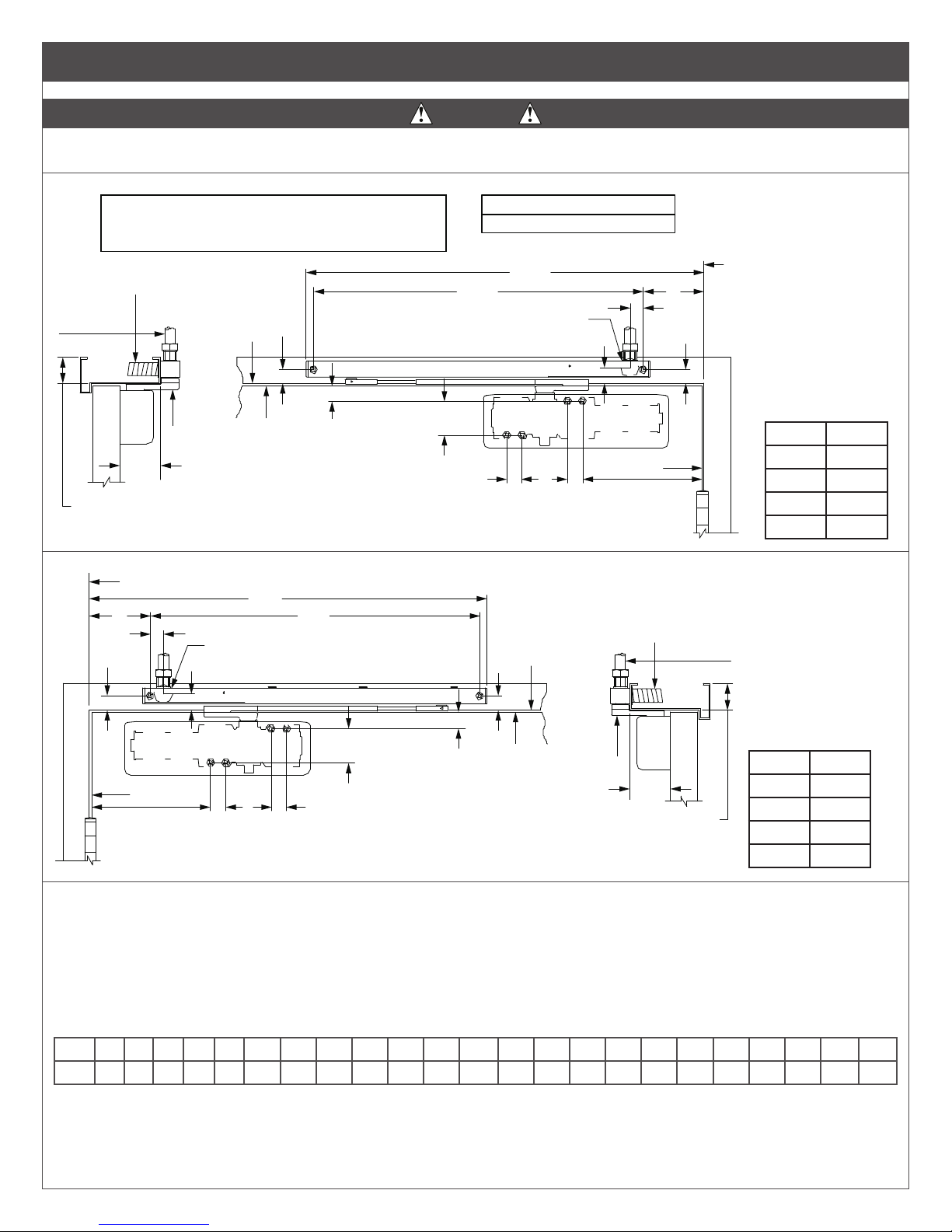

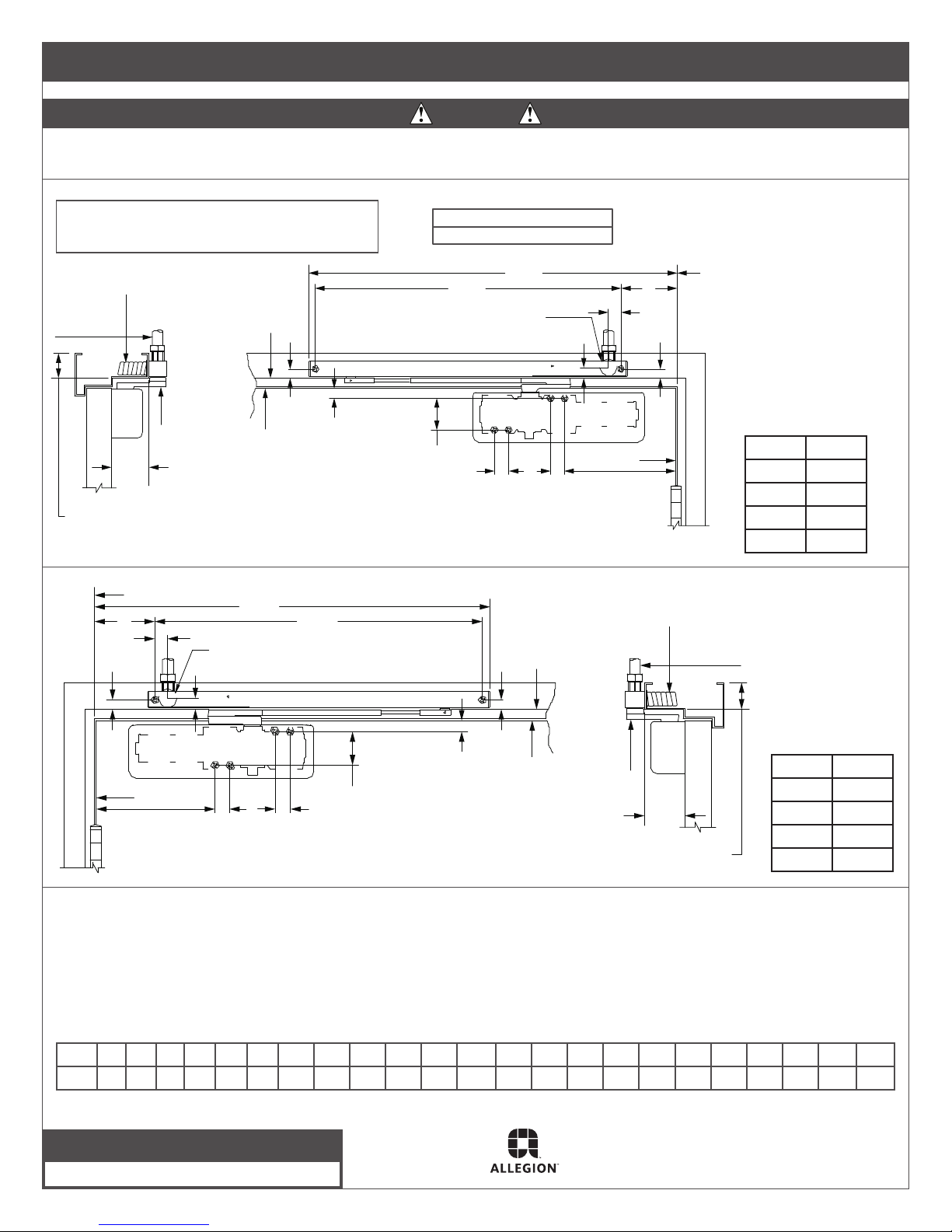

This closer features mounting options for both standard and step-down double egress frames. Before beginning, determine which type of

mounting best applies to your application, or has been specied for the job, then be sure to use the proper template.

Double Egress

4040SE

Installation Instructions

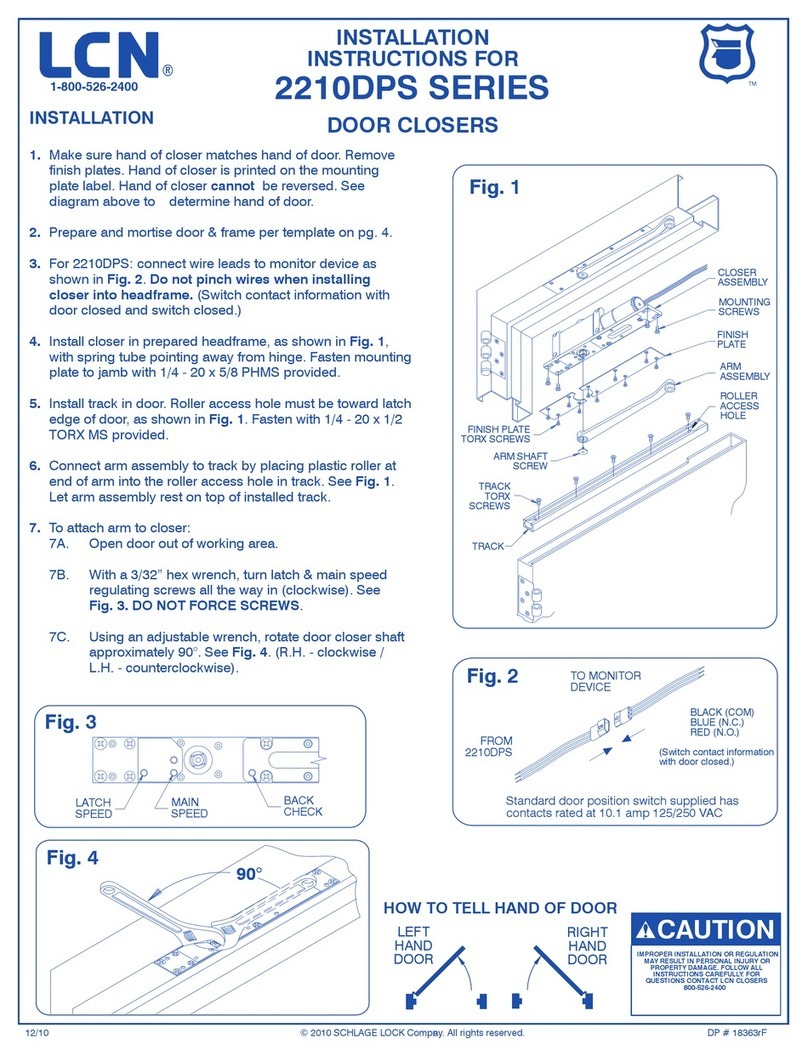

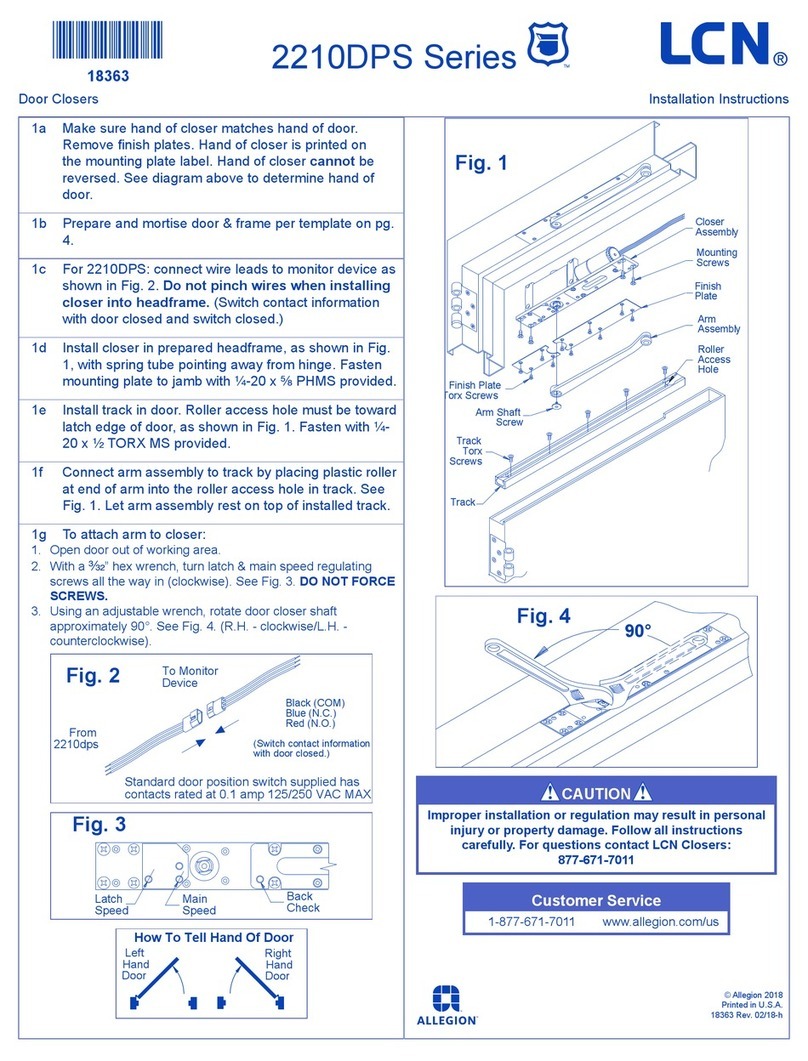

1 Voltage

The voltage shown on the track cover plate must match voltage

supplied to door frame (24V or 120V). If concealed wiring is

desired, prepare the frame to specications shown on the

corresponding template. If surface wiring is desired, be sure to

mount the track on the frame before running any EMT/conduit.

2 Track

Insert the proper track plugs into the top of the track. Using the

fasteners provided, mount the track on the frame to the template

dimensions being used. Make the electrical connections (see page

2).

3 Spring Power

Before mounting closer, the spring power may need adjusting.

Refer to the label on the closer spring tube. The 4040SE DE Series

comes preset at size 3. This will control a door up to 38”, adjust

the closer as shown (see illustration to the right) up to 7 full turns.

Starting the cover screws at this point is recommended. Using the

fasteners provided, mount the closer on the door to the dimensions

of the template being used.

4 Arm Installation

Place the arm spacer over the top shaft of the closer. Install the

arm as follows:

Place the arm spacer over the top shaft of the closer. Rotate the

arm from the door until ats in the arm hub line up with the rst

available ats of the shaft. Slide the arm hub onto the closer shaft.

Inser the shaft screw and tighten securely.

5 Arm Screw

Loosen the set screw in the arm. Connect the arm to the track

roller, and tighten the set screw rmly.

6 Door Position

To adjust the hold-open position of the door: Remove the screw

in the adjustable arm, and open the door to the desired position.

Reinsert the screw and tighten securely.

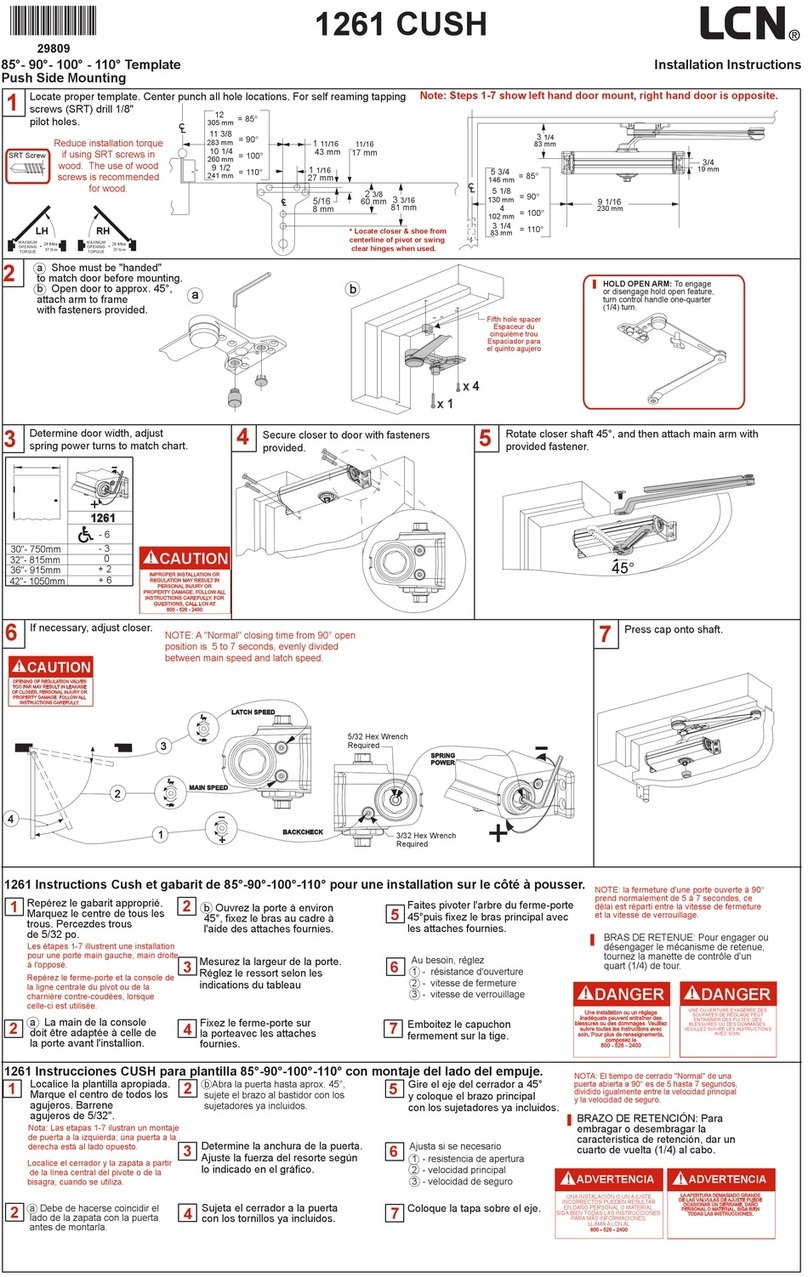

7 Regulation

Do not allow the door to slam into the frame. A “normal” closing

time from a 90° position is 5 to 7 seconds, evenly divided between

the Main and Latch Speed. If adjustments are needed, use a C\cx"

hex wrench. To adjust the Main Speed, turn the regulating screw

(see illustration) clockwise to slow the speed or c.c.w. to increase

the speed. Latch Speed is adjusted in the same way. When

adjusting, use the Backcheck the least amount necessary to slow

the swing of the door sufciently. To adjust the Backcheck, turn the

regulating screw clockwise to increase the amount of force or c.c.w.

to reduce the amount of force.

LNOTE: Do not use an abrupt backcheck setting or expect

the door closer to act as a stop!

8 Door Closer Cover

With regulation done, place the snap-on clip insert into the proper

cutout, then the snap cover assembly onto the spring tube.

CAUTION

Improper installation or regulation may result in personal

injury or property damage. Follow all instructions carefully.

For questions, call LCN at 877-671-7011.

Maximum Opening Force

=

35 ft-lbs

62 N

48 N-m

To

Increase

Power

Main

Speed

Latch

Speed

Backcheck

⁵⁄₃₂”

Hex

Wrench

Backcheck

Main

Speed

Latch

Speed