Imprint

Copyright © 2018 Arnold & Richter Cine Technik GmbH & Co. Betriebs KG.

All rights reserved.

No parts of this document may be reproduced without prior written consent of Arnold & Richter Cine

Technik GmbH & Co. Betriebs KG. Specifications are subject to change without NOTE. Errors,

omissions, and modifications excepted.

ARRI, ALEXA, AMIRA, LDS and LENS DATA SYSTEM are trademarks or registered trademarks of

Arnold & Richter Cine Technik GmbH & Co. Betriebs KG.

All other brands or products are trademarks or registered trademarks of their respective holders and

should be treated as such. Original version.

For further assistance:

Arnold & Richter Cine Technik GmbH & Co. Betriebs KG

Türkenstr. 89

80799 München

Germany

www.arri.com

Document revision history

Version Order Nr Release Date

1.0 01.12.2019

Scope

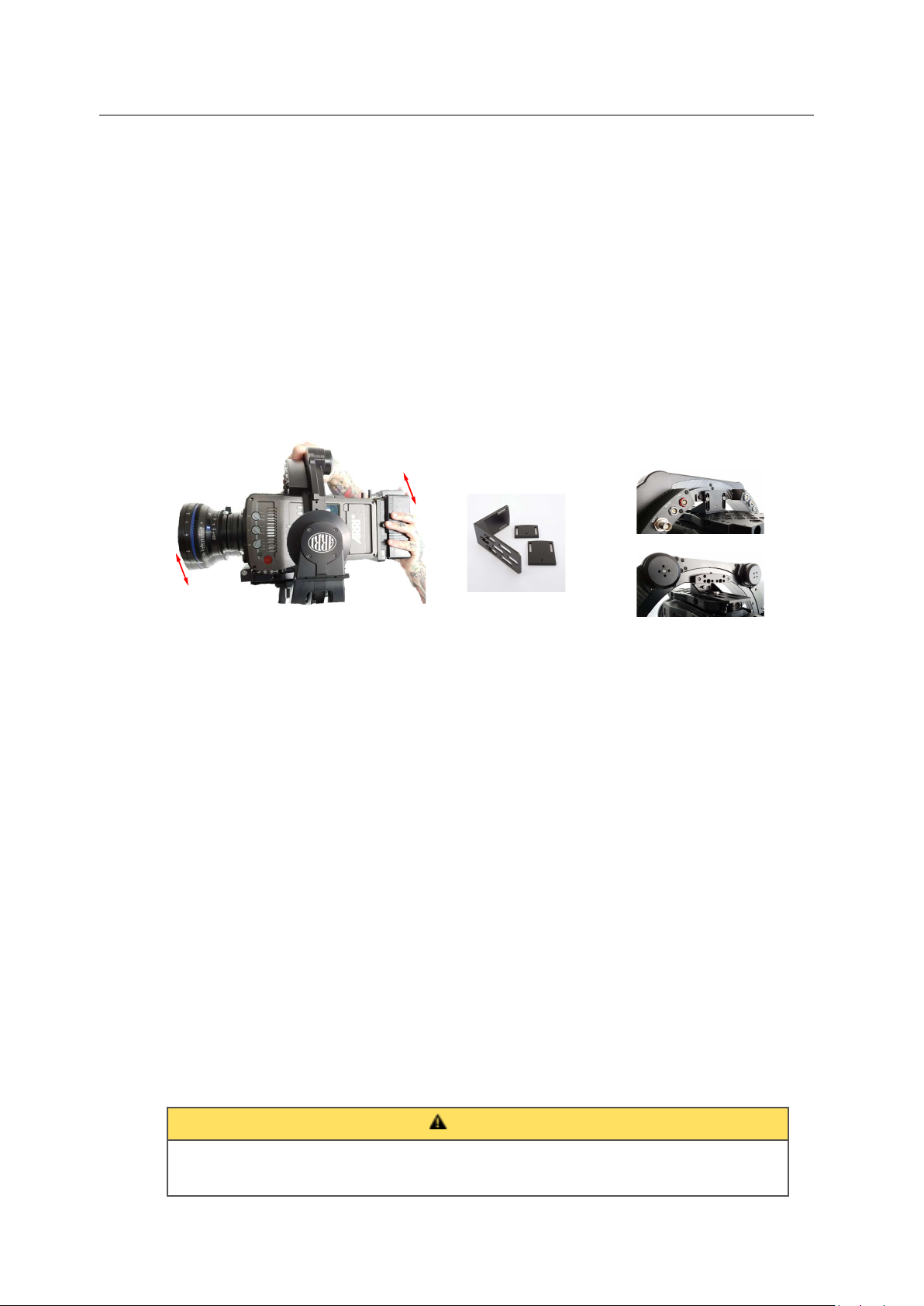

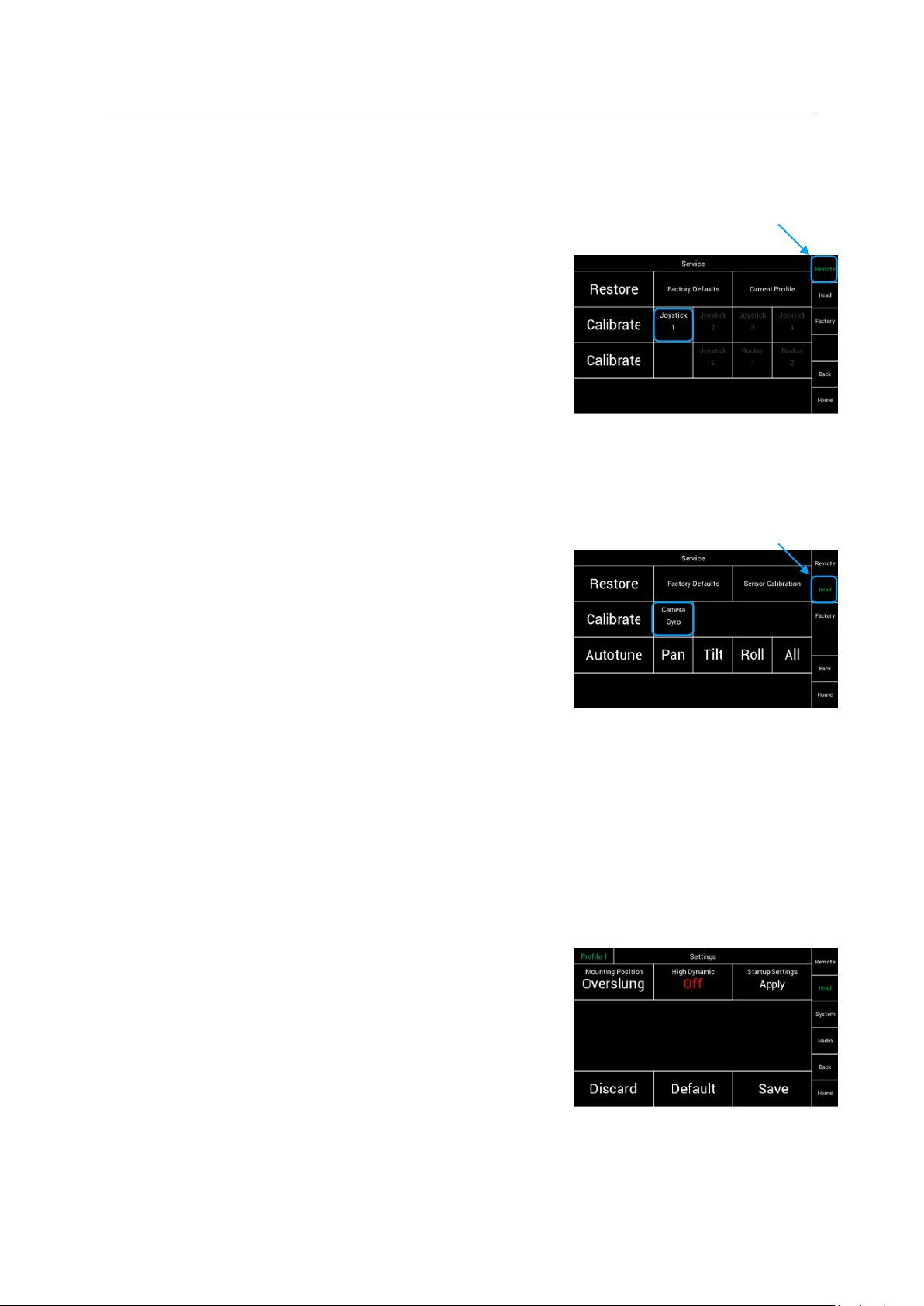

This document describes the components and the setup and programming of the SRH-3 Remote

Control.

Disclaimer

Before using the products described in this manual, be sure to read and understand all the respective

instructions.

Otherwise the customer must contact ARRI before using the product.

While ARRI endeavours to enhance the quality, reliability and safety of their products, customers

agree and acknowledge that the possibility of defects thereof cannot be eliminated entirely. To

minimize the risk of damage to property or injury (including death) to persons arising from defects in

the products, customers must incorporate sufficient safety measures in their work with the system and

heed the stated conditions of use.

ARRI or its subsidiaries do not assume any responsibility for losses incurred due to improper handling

or configuration of the TRINITY or other system components.

ARRI assumes no responsibility for any errors that may appear in this document.

The information is subject to change without NOTICE.

For product specification changes after this manual was published, refer to the latest published ARRI

data sheets or release notes, etc., for the most up-to-date specifications.

Not all products and/or types are available in every country. Please check with an ARRI sales

representative for availability and additional information.

Neither ARRI nor its subsidiaries assume any liability for infringement of patents, copyrights or other

intellectual property rights of third parties by or arising from the use of ARRI products or any other

liability arising from the use of such products. No license, express, implied or otherwise, is granted

under any patents, copyrights or other intellectual property right of ARRI or others.

ARRI or its subsidiaries expressly exclude any liability, warranty, demand or other obligation for any

claim, representation, cause, action, or whatsoever, express or implied, whether in contract or not,

including negligence, or incorporated in terms and conditions, whether by statue, law or otherwise. In

no event shall ARRI or its subsidiaries be liable for or have a remedy for recovery of any special,

direct, indirect, incidental, or consequential damages, including, but not limited to lost profits, lost

savings, lost revenues or economic loss of any kind or for any claim by a third party, downtime, good-

will, damage to or replacement of equipment or property, any cost or recovery of any material or

goods associated with the assembly or use of our products, or any other damages or injury of the

persons and so on or under any other legal theory.

In the event that one or all of the foregoing clauses are not allowed by applicable law, the fullest

extent permissible clauses by applicable law are validated.