ASM GmbH MAN-PRAS-EX-E-13 9

www.asm-sensor.com

Torque Mounting method Material Torque

[Nm]

M2,5 screws for mounting brackets (PRAS2,

PRAS3) – 0.8

M3 screws for mounting ange (PRAS3) – 1.2

M8 screws (PRAS5) – <20

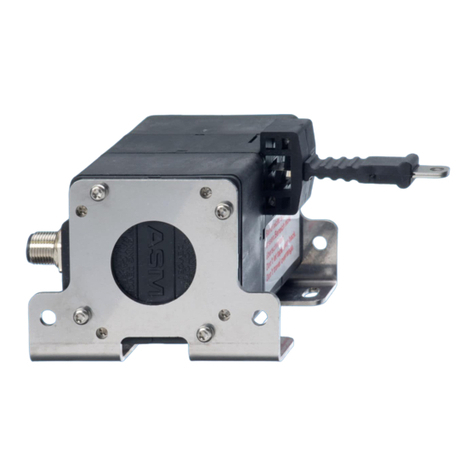

POSIROT®EX

Instruction Manual

• Optional to the locking clip an ATEX approved M12 connector /

socket can be used, which can removed only with special tools.

• Cables must be xed rmly and protected against damage.

• Protect cables against UV radiation.

• Do not turn the M12 connector insert.

• A separate cord grip is recommended.

Mechanical information

• Do not mount the sensor in dust condition.

• Avoid dust deposit.

• Do not expose the sensor to shocks, the housings have been

tested with low impact energy (DIN EN 61241-0).

PRAS2EX-M12A Impact energy 4J

PRAS2EX-M12R Impact energy 4J

PRAS3EX-M12A Impact energy 4J

PRAS3EX-M12R Impact energy 4J

PRAS5EX-M12A Impact energy 4J

PRAS5EX-M12R Impact energy 4J

PRAS5EX-V-M12A Impact energy 4J

PRAS5EX-V-M12R Impact energy 4J

• Do not expose the sensor to shocks or any kind of impacts.

• Tightening torque – see following table.

Torque of the xing screws

Mechanical information for PRAS3EX

• Mount the sensor mechanical strainless

• Use shaft couplings resp. torque arms (e.g. exible ones) to avoid

misalignment errors.

• Use electrically conductive shafts/torque arms.

• Provide protection devices to avoid blocking of sensor by strange

parts falling into the working area.

• The max. number of revolutions is 1000 1/min (1000 RPM)

Removal

Remove sensor only in de-energized condition.

Mounting

(continuation)