ASM GmbH MAN-PRAS-E-15 3

www.asm-sensor.com

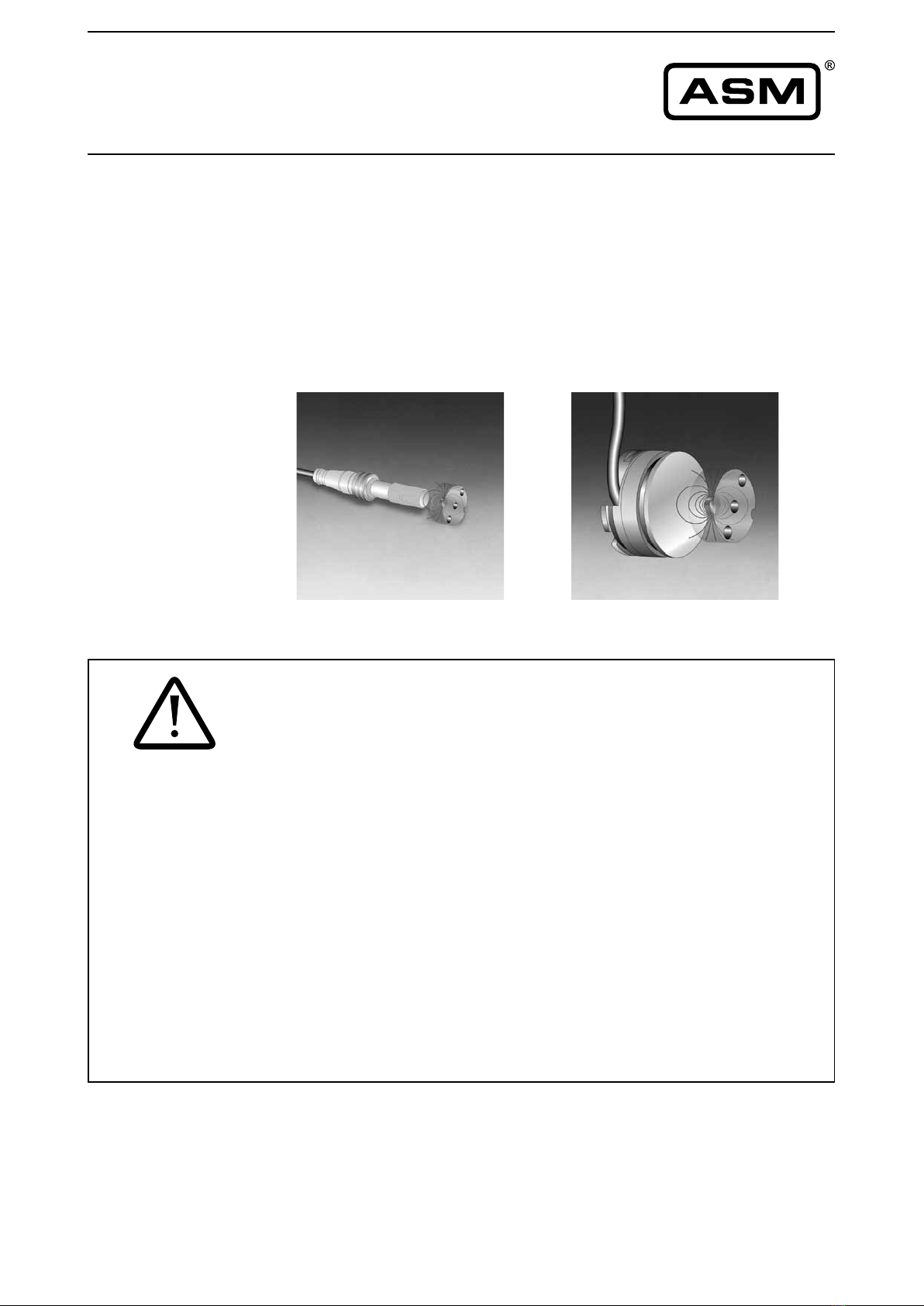

POSIROT®

Instruction Manual

Do not use POSIROT®position sensors in safety critical appli-

cations where malfunction or total failure of the sensor may

cause danger for man or machine.

For safety related applications additional mechanisms (de-

vices) are necessary to maintain safety and to avoid damage.

Disregard of this advice releases the manufacturer from pro-

duct liability.

The sensor must be operated only within values specied in

the catalog or datasheet.

Connection to power supply must be performed in accordance

with safety instructions for electrical facilities and performed

only by trained staff.

Safety

instructions

Explanation of used

safety signs and

signal words

WARNING, Risk of Injury:

Indicates a potentially hazardous situation, which,

if not avoided, could result in serious injury or

property damage.

WARNING, Risk of Personal Injury or Death:

Indicates a situation that can result in serious personal

injury or death if not properly avoided.

DANGER

WARNING, Risk of Personal Injury or Death:

Indicates a situation that can result in moderate

personal injury or death if not properly avoided.

WARNING

WARNING, Risk of Personal Injury:

Indicates a situation that can result in minor personal

injury if not properly avoided.

CAUTION

WARNING, Risk of Property Damage:

Indicates a situation that can result in minor to major

property damage if not properly avoided.

NOTICE