2 MAN-PRDS-E-17 © by ASM GmbH

www.asm-sensor.com / USA: www.asmsensors.com

Contents

POSIROT®– PRDS

Contents

Safety instructions........................................................................ 3

Intended use...................................................................................4

Unintended use..............................................................................4

Delivery / shipment........................................................................5

Description..................................................................................... 6

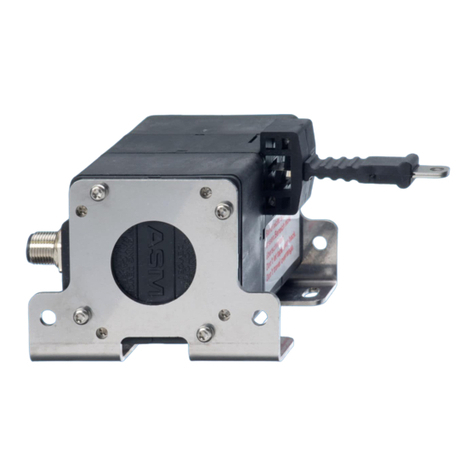

Mounting........................................................................................ 6

Placement and alignment of the position magnet..........................6

Reference position........................................................................ 7

Torque for the mounting screws.................................................... 7

Electrical installation.....................................................................9

.

Reference position.......................................................................10

PRDS27.................................................................................. 10

PRDS1.................................................................................... 11

PRDS2.................................................................................... 12

PRDS3.................................................................................... 12

PRDS5.................................................................................... 13

PRDS6.................................................................................... 14

PRDS7.................................................................................... 15

Specification of the outputs........................................................16

RS422..................................................................................... 16

HTL......................................................................................... 17

SSI.......................................................................................... 18

CANopen.................................................................................19

CAN SAE J1939......................................................................30

Accessories..................................................................................35

Accessory cables.................................................................... 35

Position magnets.................................................................... 37

Assembly of the magnets........................................................45

Mounting plates for PRDS2/PRDS3....................................... 46

Mounting possibilities PRDS2/PRDS3................................... 47

Coupling MK4..........................................................................48

Service, calibartion, disposal..................................................... 49

Reliability Characteristics...........................................................50

Declaration of conformity............................................................51