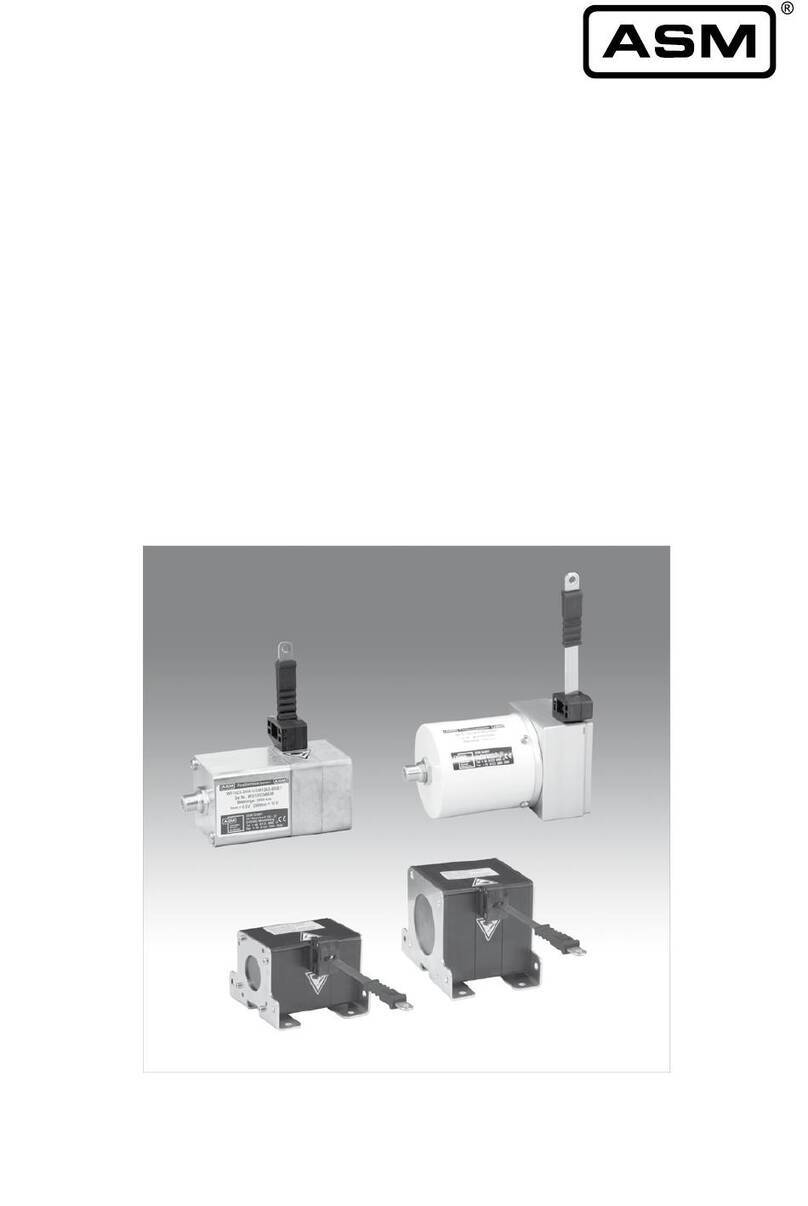

positilt®

Inclination Sensors PTM series

Gyro-compensated Inclination Sensors PTK series

4

www.asm-sensor.com

Pos: 6/Be di en ungs a nlei tung en /Mo d ule U ni ver sal /Ü ber schr if te n/Si ch er heits hi nw eis e U E @ 6\mod_1507630884828_78.docx@ 48429@ 1 @ 1

1 Safety instructions

Pos: 7 / Si ch er hei ts hi nwei s e/ Si g nal wör t er und Sym b ol e UE @1\m od_1400140467807_78.docx@ 9166 @ 2 @ 1

1.1 Signal words and symbols

Pos: 8 / Si ch er hei ts hi nwei s e/ Si g nal wör t er @1 \mod_1400240492762_78.docx@ 9385 @ @1

WARNING, Risk of Injury:

Indicates a potentially hazardous situation, which, if not avoided, can result in serious

injury or property damage.

WARNING, Risk of Personal Injury or Death:

Indicates a situation that can result in serious personal injury or death if not properly

avoided.

WARNING, Risk of Personal Injury or Death:

Indicates a situation that can result in moderate personal injury or death if not properly

avoided.

WARNING, Risk of Personal Injury:

Indicates a situation that can result in minor personal injury if not properly avoided.

WARNING, Risk of Property Damage:

Indicates a situation that can result in minor to major property damage if not properly

avoided.

Product liability

•Disregarding the following instructions may result in malfunction, damage to property and personal injury

and releases the manufacturer from product liability.

Safety regulations

•National safety regulations must be observed!

Pos: 9/Si ch er hei ts hi nwei s e/ All g_Si c h erh eits hi nw ei se U E @ 0\mod_1385398033298_78.docx @ 2610@ 2 @ 1

1.2 General safety instructions

Pos: 10 /Sich erh eit s hinw ei s e/Sic h er hei ts hinw ei s e_ PT @8\mod_1557828733936_78.docx@63907 @ @1

Danger of injury to the operator or damage to the property

•Connection to power supply must be performed in accordance with safety

instructions for electrical facilities and performed only by qualified personnel.

•Any alteration, reconstruction or extension of the sensor is not allowed!

•The sensor must be operated only within values specified in the datasheet.

•The danger of personal injury and danger of property damage due to a

malfunction of the sensor in machines or systems must be excluded by

additional safety measures.

•In safety-relevant applications, additional facilities must be provided for

maintaining safety and preventing damage.

•Check whether the protection class of the sensor is suitable for the application.

Mechanical damage or destruction of the sensor

•Do not open the sensor.

•Avoid impact and shock to the sensor.

Pos: 11 / ##### ##### # Seite numbr uch ###################################@ 0\mod_1353584168894_0.docx@ 336 @ @1