posirot®

Magnetic Angle Sensors PRDS-CANOPR, PRDS-J1939R

Version 1.0.0

www.asm-sensor.com

Pos: 17 /Bedienungs anleitungen/Mo duleU niversal/Überschrift en/Montage, I nbetriebnahme UE @ 4\mod_1491474 694256_78.doc x@ 38 324 @ 1 @1

3 Installation and initial operation

Pos: 18 /Bedienungsanl eitungen/Posirot/PRD S/CANOPEN_PRDS/ Beschreibung_PRD S@ 3\ mod_14543189 26894_78.docx @ 22302 @ @ 1

Description of the PRDS sensors

The angle sensors PRDS of the posirot®product family perform non-contact or shaft-based angle

measurement. A position magnet rotates in front of the sensing area of the sensor head.

The sensor detects the angular position of the position magnet and outputs an absolute digital position value

(CANopen, SAE J1939).

Pos: 19 /Bedienungsanl eitungen/Posirot/PRD S/CANOPEN_PRDS/M ontage_Anordnu ng_PRDS @ 3\mod_14 54319689520_78.d ocx@ 223 14@ 2 @ 1

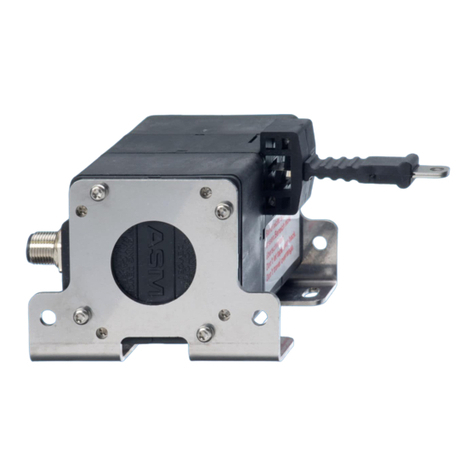

3.1 Mechanical installation

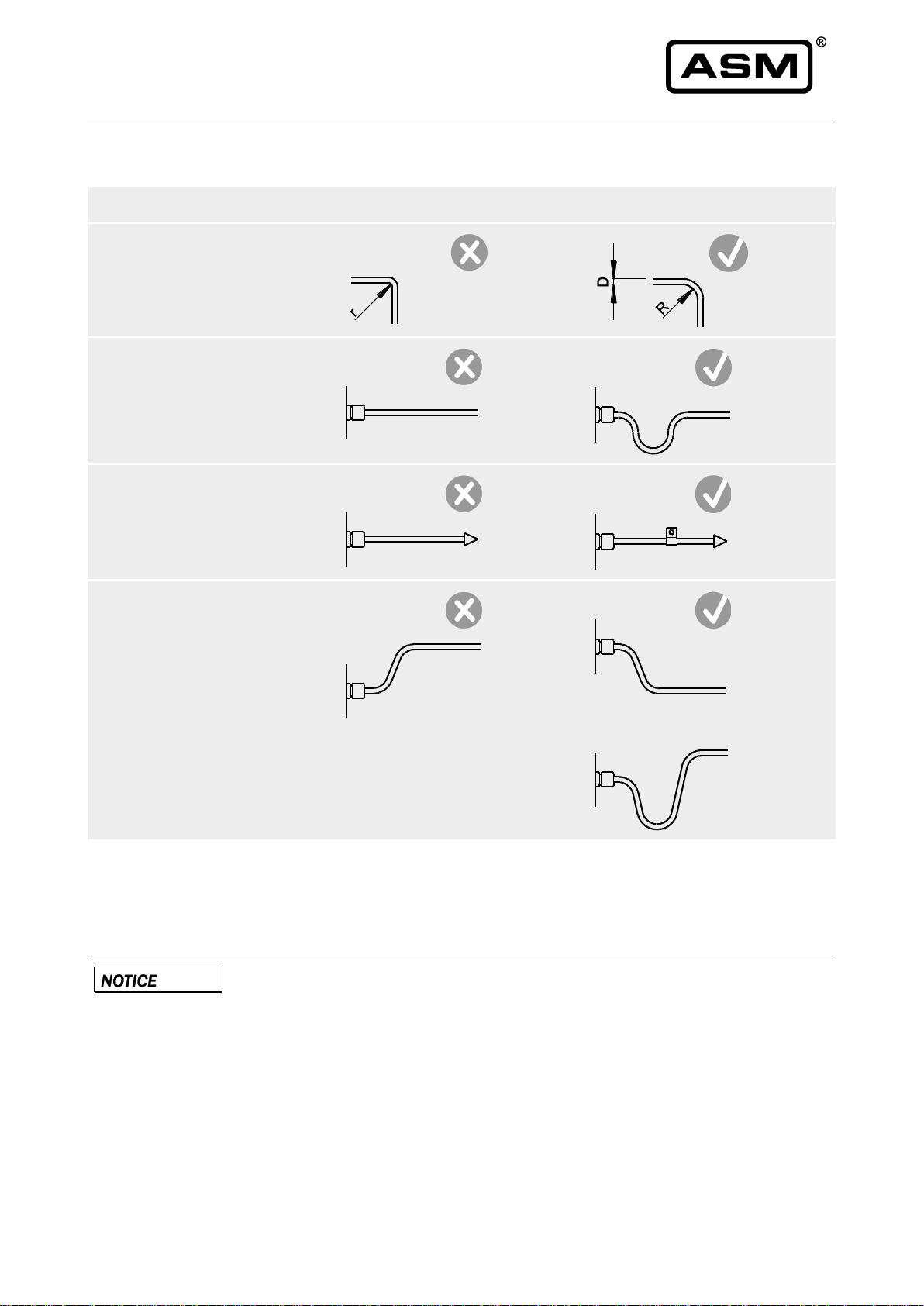

•Mount the sensor without mechanical strain.

•For sensors with shaft use flexible coupling or torque arms to avoid misalignment errors (see page 12

“Couplings”).

Mechanical information for the PRDS27 sensor:

•Mount the sensor on a flat surface.

•Do not deform the sensor housing!

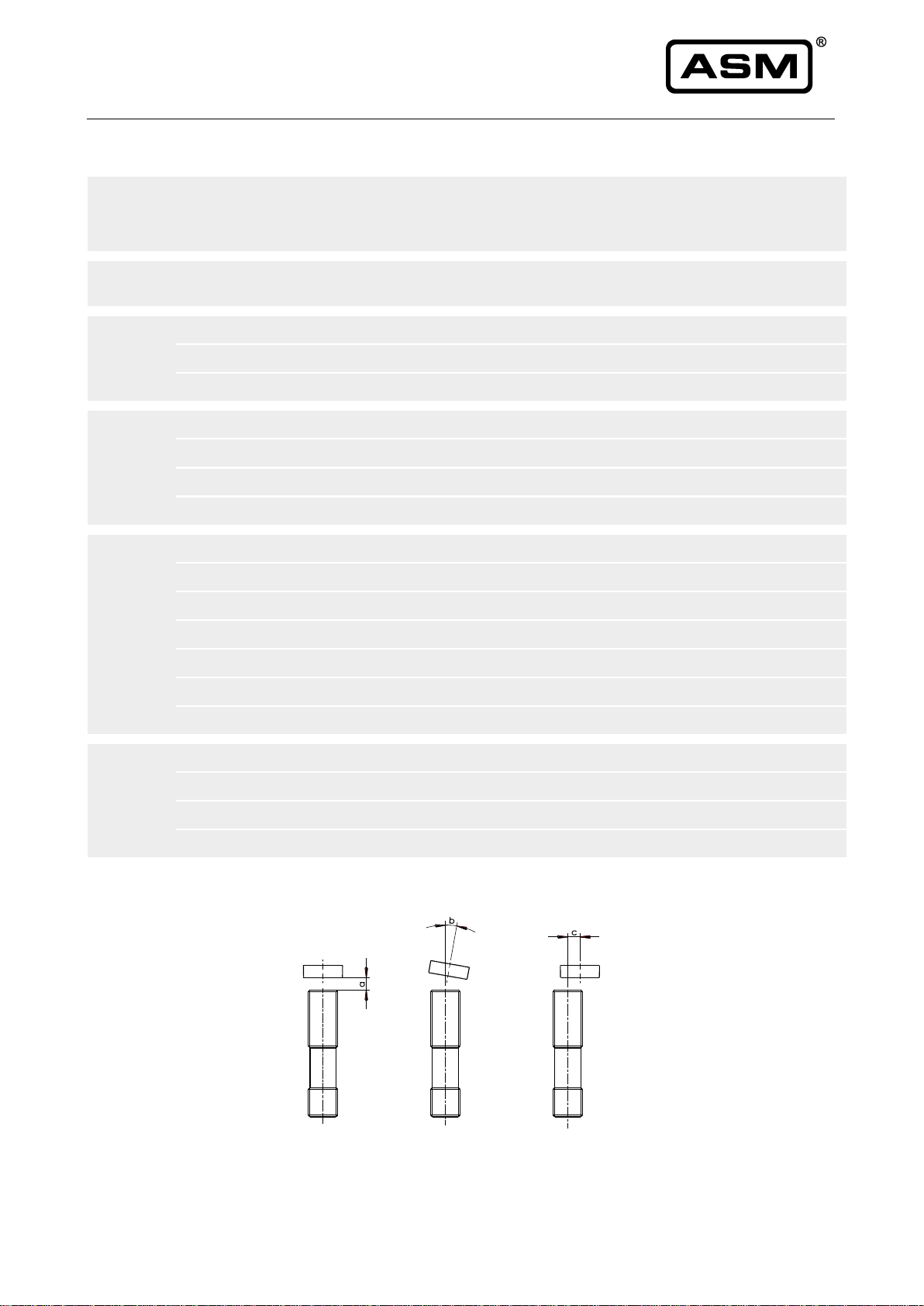

Placement and alignment of the position magnet

For non-contact sensor models air gap and alignment of sensor and position magnet has to be observed. The

linearity will degrade in case of misalignment.

Adjacent magnetic fields or ferromagnetic materials can influence the measurement results of the PRDS

sensors of the posirot®product family. Therefore, the angle sensors and position magnets should be mounted

solely with nonmagnetic / non magnetisable screws and washers.

The angle sensors PRDS1, PRDS2, PRDS3, PRDS5, PRDS6 and PRDS7 are equipped with an integrated

magnetic shield which minimizes the sensitivity against external magnetic fields.

An optional shield plate is available for the angle sensors PRDS27 and PRDS29. It can reduce the effect of

residual magnetizing in case the sensor has to be mounted on a ferromagnetic material.

It is however not possible to exclude the effect of lateral external magnetic fields.

Pos: 20 /Bedienungsanl eitungen/Posirot/PRD S/Elektrischer Anschluss _PRDS@ 8 \mod_1555 488531714_78.docx @ 63431 @ 2 @ 1