Damage or destruction of the sensor due to excessive operating voltage or

mounting error

•The applied operating voltage must not exceed the value specified in the data

sheet.

•Operate the sensor only within the limits specified in the data sheet.

•Connection to the power supply only by qualified personnel and in accordance with

the applicable safety regulations for electrical equipment.

•Do not connect or disconnect the sensor under tension!

Corrosion in the sensor due to moisture penetration

•Use the sensor only according to protection class.

•Avoid crossing the dew point.

•Cable outputs must be installed in such a way that no moisture can get into the

cable.

•The protection class of sensors with connector output is valid only if the electrical

plug is connected!

Damage of the sensor cable due to mechanical stress

•Use only M12 sockets approved in compliance with ATEX which allow

deinstallation only with tools, eg. EVC 04A or EVC 05A of ifm/Essen.

•Do not twist the M12 connector insert.

•It is important that the knurled nut on the connector is tightened to the correct

torque, according to the manufacturer’s instruction. Use a torque wrench, if

needed.

•Cable must be properly secured and protected against damage.

•Cable must be protected from UV-radiation!

•Installation according to DIN EN 60079-14.

•Do not strain the connection cable.

•A separate strain relief is recommended.

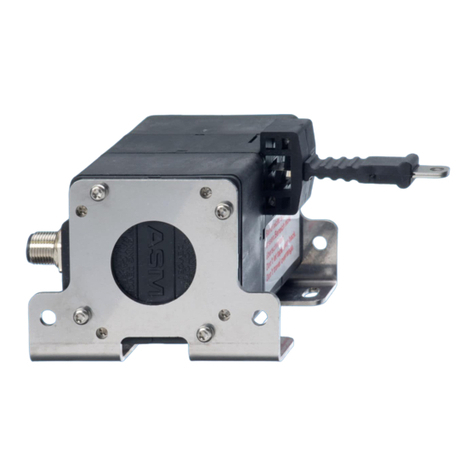

Connector Pin assignment

According to the definitions of the output types contained in the appendix. Observe different color code for

pre-assembled accessory cables. See catalog information for accessories.

Connect the cable screen - if present - to the local potential equalizer.

Follow the signal wiring table!

Supply voltage

See specification in the data sheet of the sensor. The maximum operating voltage must not be exceeded.

Pos: 23 /######## ### Seitenumbruch #### ########### ############## ###### @ 0\mod_13 53584168894_0.d ocx @ 336 @ @ 1