Assa Abloy Norton 6011 Series User manual

Other Assa Abloy Door Opening System manuals

Assa Abloy

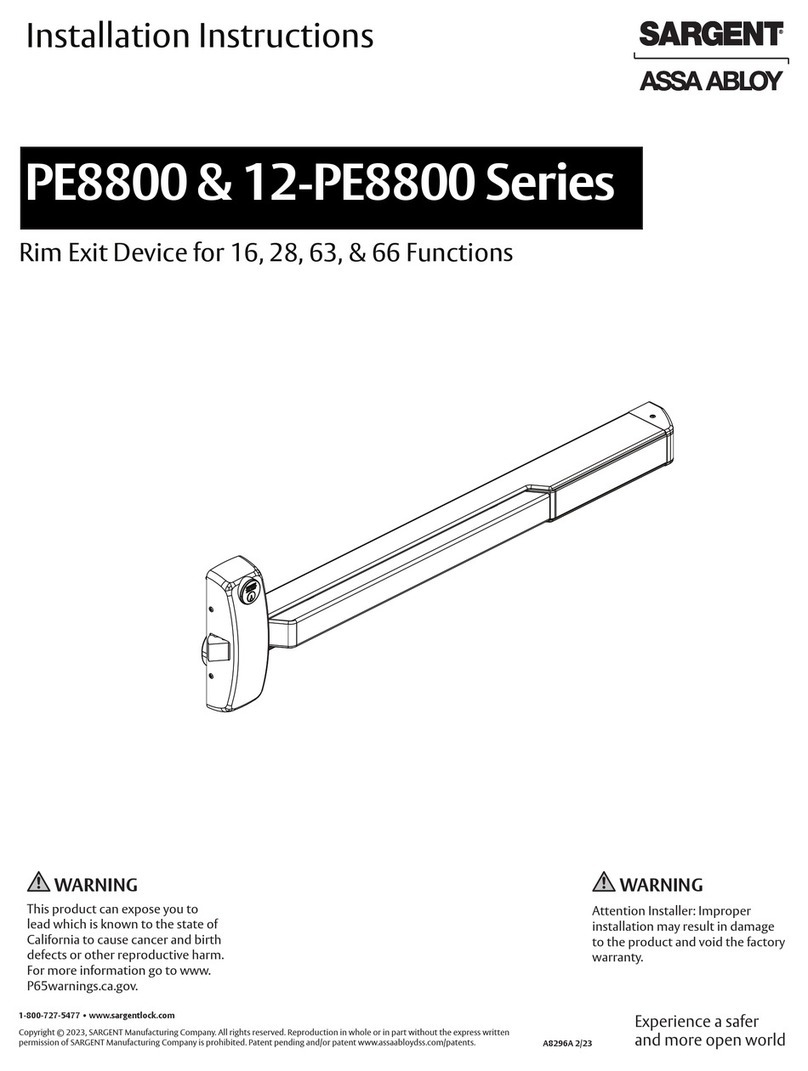

Assa Abloy Sargent PE8800 Series User manual

Assa Abloy

Assa Abloy G-CO-FMS User manual

Assa Abloy

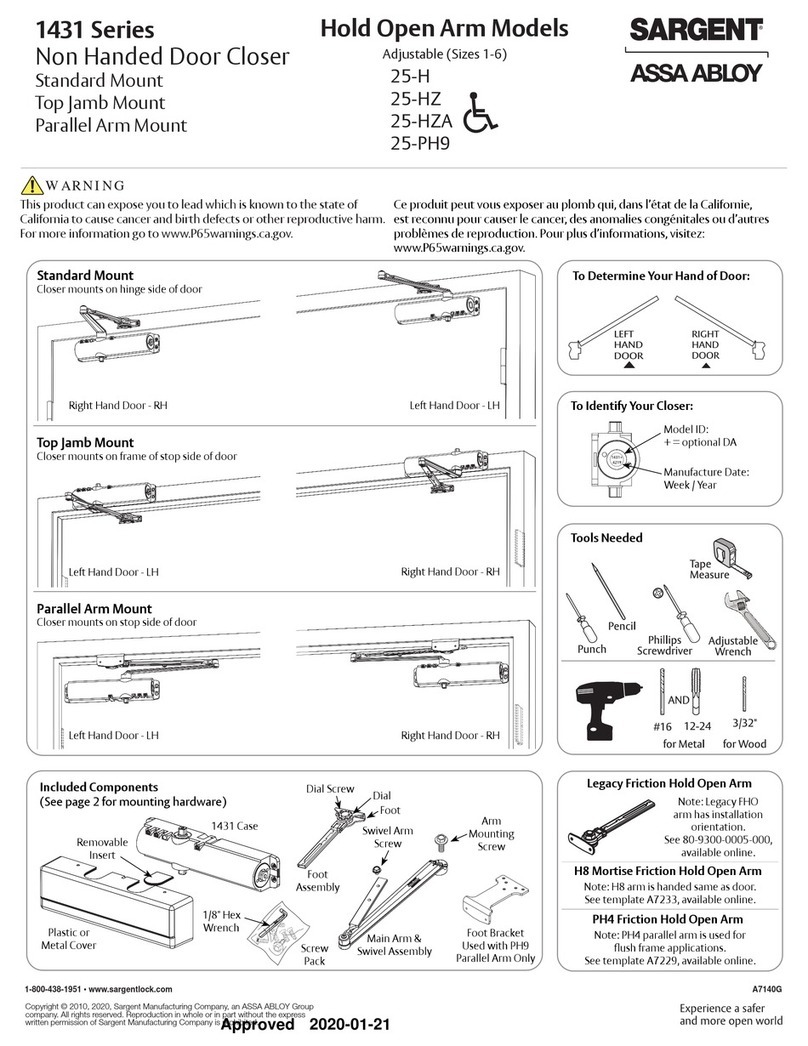

Assa Abloy Sargent 1331 User manual

Assa Abloy

Assa Abloy Norton 8000H Series User manual

Assa Abloy

Assa Abloy Corbin Russwin DC8200 Series User manual

Assa Abloy

Assa Abloy DC140 User manual

Assa Abloy

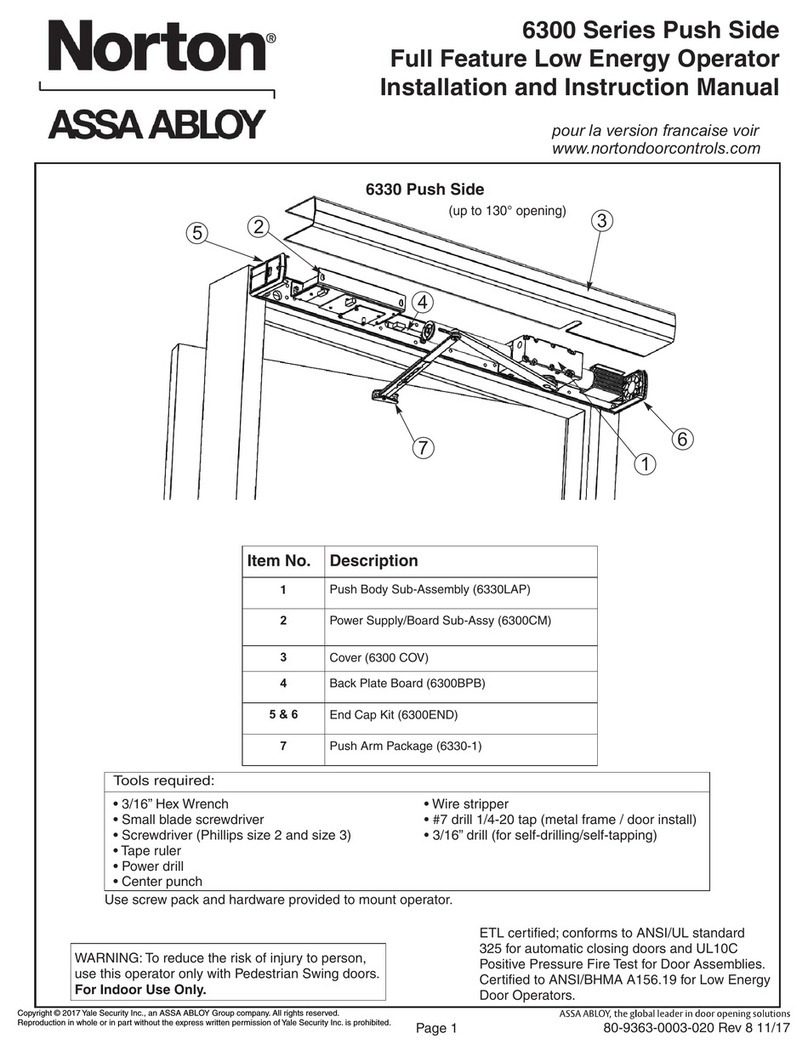

Assa Abloy Norton 6300 Series Quick guide

Assa Abloy

Assa Abloy Corbin Russwin PED5200 User manual

Assa Abloy

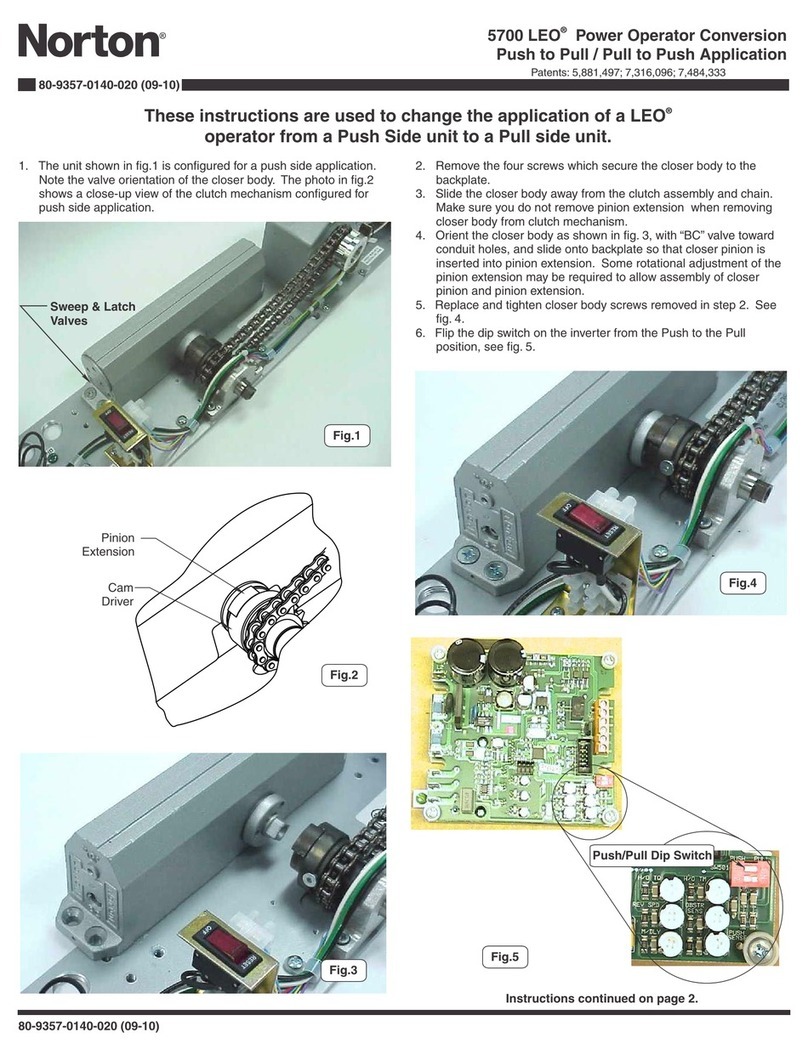

Assa Abloy Norton LEO 5700 Series User manual

Assa Abloy

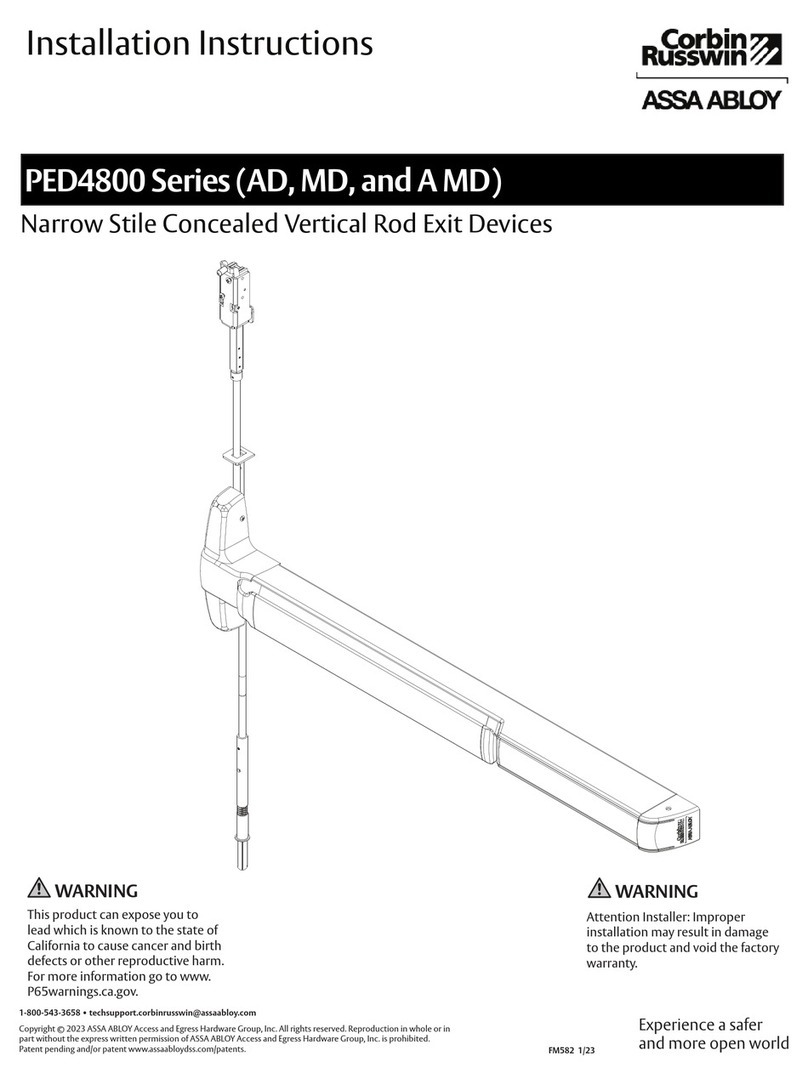

Assa Abloy Corbin Russwin PED4800 Series User manual

Assa Abloy

Assa Abloy Norton 6300 Pull Side Series Quick guide

Assa Abloy

Assa Abloy Corbin Russwin PED4600 A Series User manual

Assa Abloy

Assa Abloy Lockwood 5831 Series User manual

Assa Abloy

Assa Abloy Corbin Russwin PED5400 FE User manual

Assa Abloy

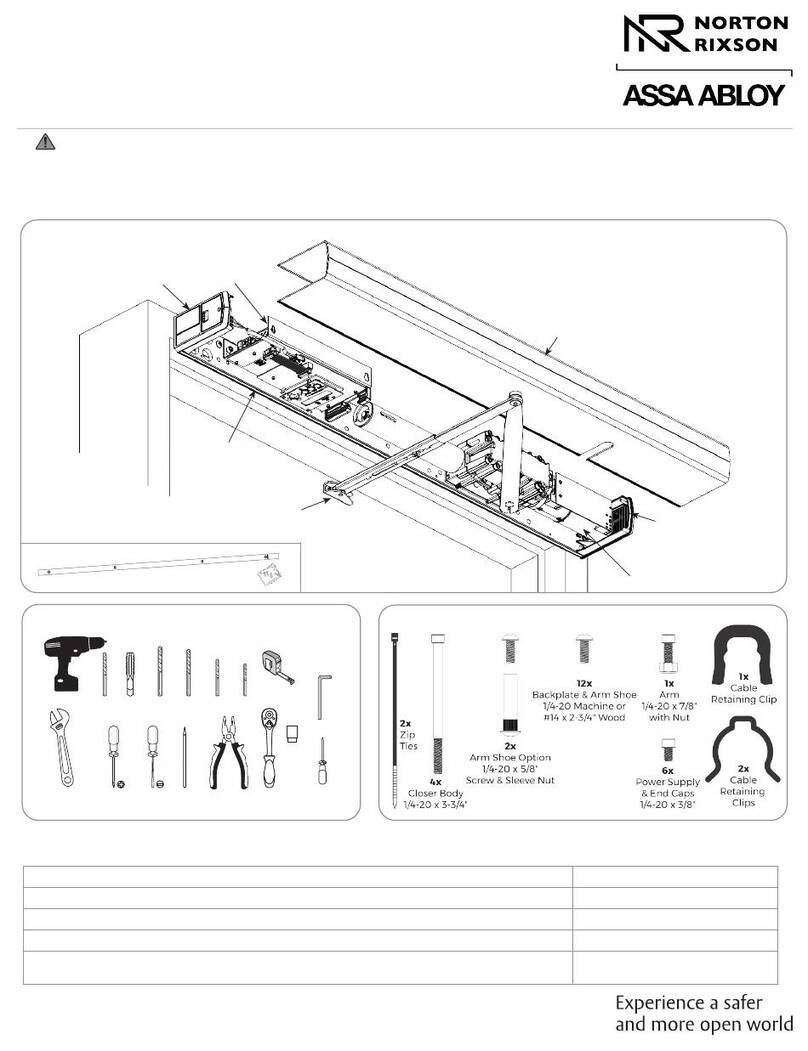

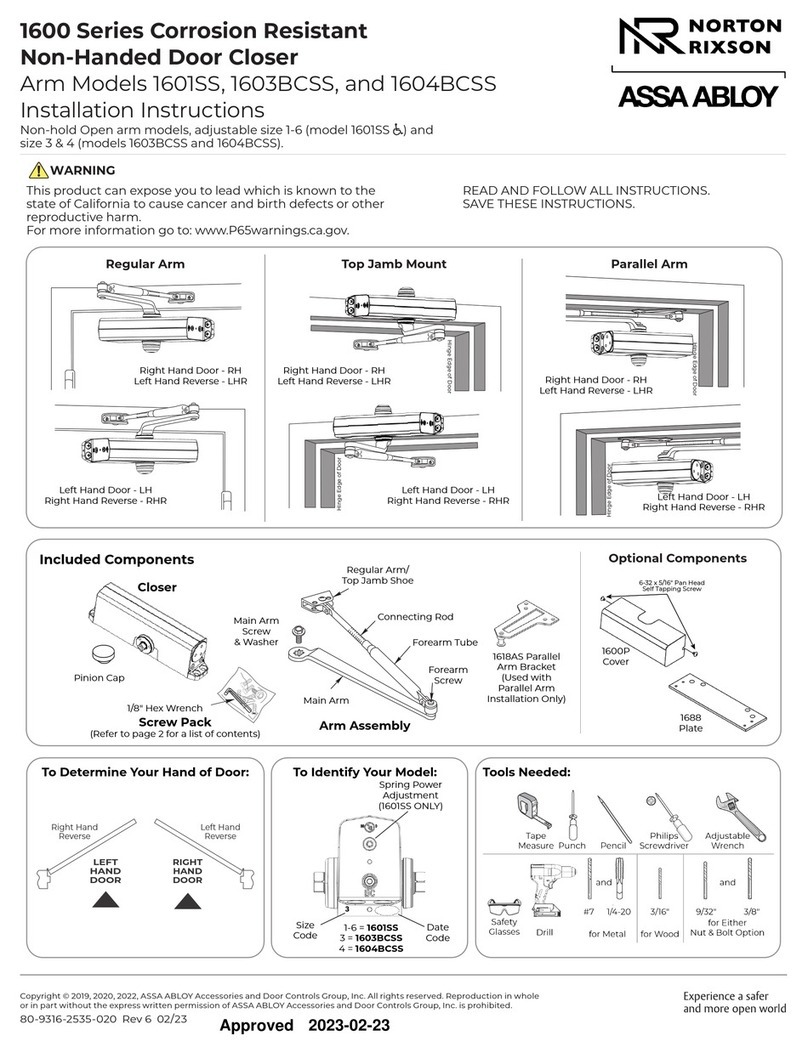

Assa Abloy NORTON RIXSON 1600 Series User manual

Assa Abloy

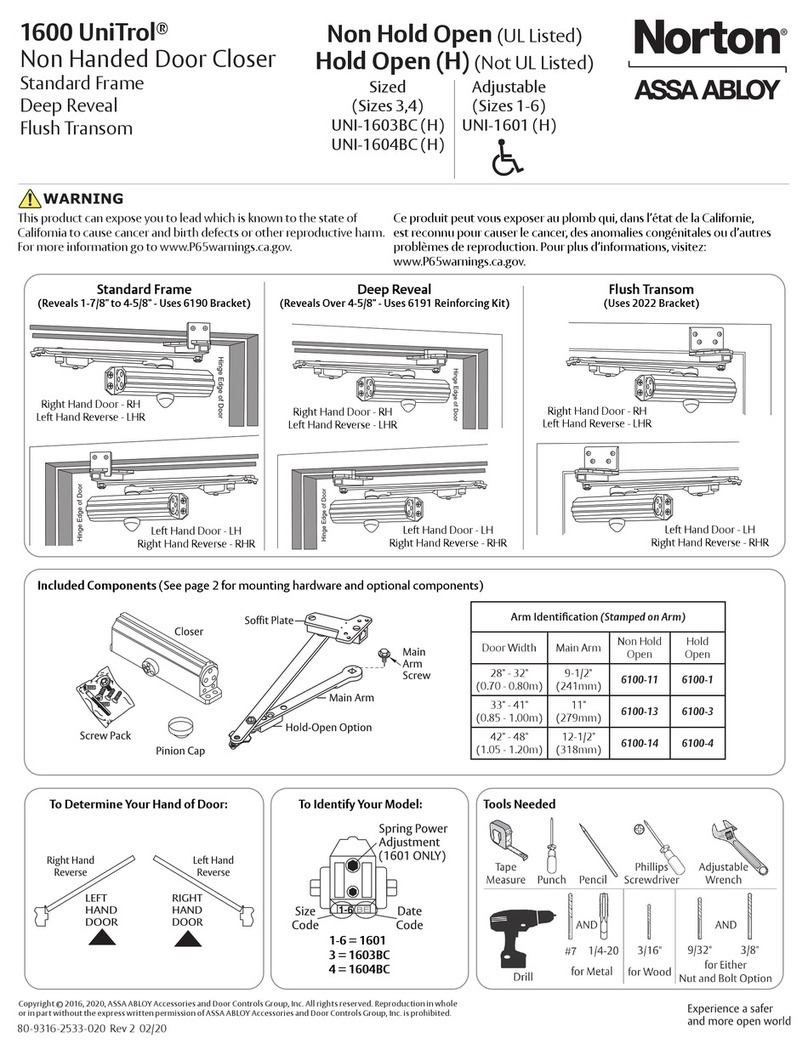

Assa Abloy Norton 1600 UniTrol User manual

Assa Abloy

Assa Abloy DC700 User manual

Assa Abloy

Assa Abloy Rixson Smok-Chek VI Quick guide

Assa Abloy

Assa Abloy RD3 User manual

Assa Abloy

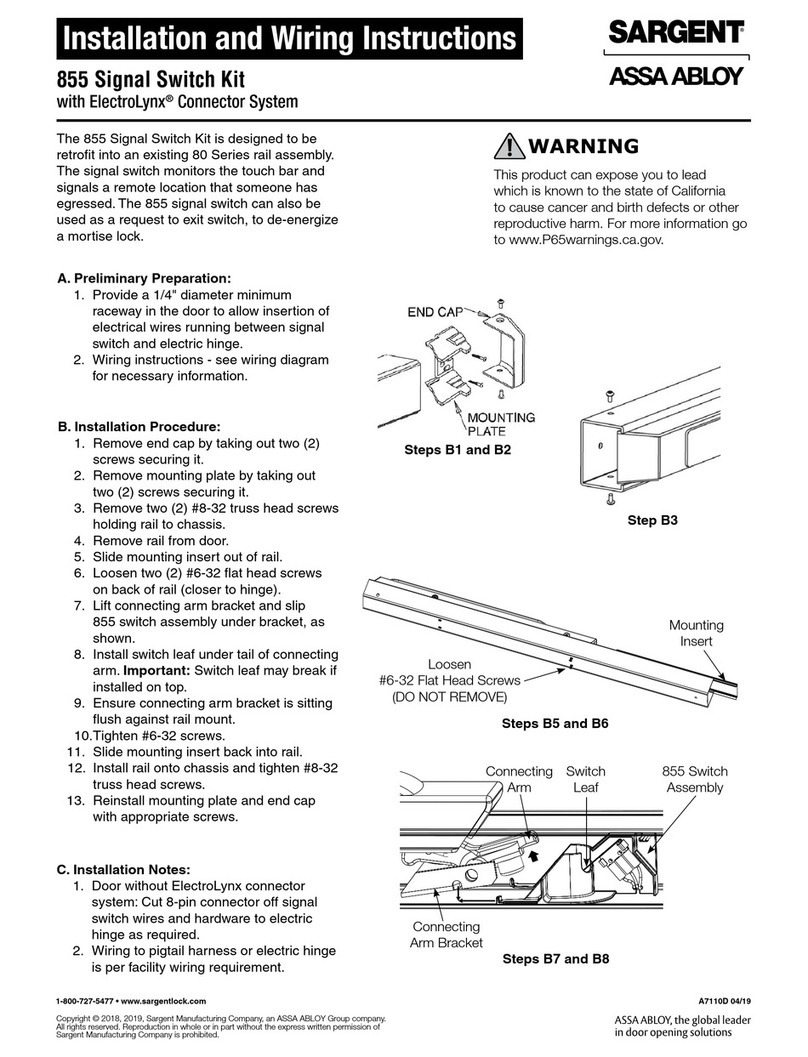

Assa Abloy Sargent 855 Assembly instructions

Popular Door Opening System manuals by other brands

Stanley

Stanley MA900ñ Installation and owner's manual

WITTUR

WITTUR Hydra Plus UD300 Instruction handbook

Alutech

Alutech TR-3019-230E-ICU Assembly and operation manual

MPC

MPC ATD ACTUATOR 50 ATD-313186 Operating and OPERATING AND INSTALLATION Manual

GEZE

GEZE ECturn user manual

Chamberlain

Chamberlain T user guide