Atmos Variotherm plus User manual

Variotherm plus

GA1GB.140302.0 2022-02 Index 31

0124

Operating Instructions

Valid for devices delivered after July 2002.

English

2

Contents

1.0 Introduction.........................................................3

1.1 Notes on operating instructions ............................3

1.2 Intended use .........................................................4

1.3 Function ................................................................4

1.4 Explanation of symbols.........................................4

2.0 For your safety....................................................5

2.1 Important instructions for the maintenance of the

hygiene status of warm water irrigation units........6

3.0 Setting up and starting up .................................7

3.1 Scope of supply ....................................................7

3.2 Illustrations............................................................8

3.3 Connections........................................................11

3.3.1 Electrical connection...........................................11

3.3.2 Connecting a nystagmograph.............................11

3.3.3 Equipotential bonding conductor connection ......11

3.3.4 Water connection ................................................12

3.3.5 Connection of the irrigation handle .....................12

3.4 Starting up...........................................................12

4.0 Operation...........................................................13

4.1 Adjusting temperatures.......................................13

4.2 Selecting temperature levels...............................13

4.3 Adjusting stimulation time ...................................13

4.4 Adjustingowquantity ........................................13

4.5 Description of operating modes ..........................14

4.5.1 Thermal process for reducing bacterial count.....14

4.5.2 Irrigation mode....................................................14

4.5.3 Stimulation mode ................................................14

4.5.4 Energy saving mode ...........................................14

5.0 Cleaning and care.............................................15

5.1 General information on cleaning and disinfection15

5.2 Recommended disinfectants...............................15

5.3 Cleaning method for handle with jet connection

for water irrigation tip ..........................................16

6.0 Maintenance and service .................................17

6.1 Decalcication.....................................................17

6.2 Replacementoflter...........................................17

6.3 Sending in the device..........................................17

7.0 Troubleshooting................................................18

8.0 Accessories and spare parts...........................19

8.1 Accessories.........................................................19

8.2 Spare parts .........................................................19

9.0 Technical data ...................................................20

10.0 Disposal.............................................................22

11.0 Notes on EMC....................................................23

12.0 Notes..................................................................26

3

1.0 Introduction

1.1 Notes on operating instructions

These operating instructions contain important notes on how

tooperatetheVariothermplussafely,correctly,andeec-

tively. Therefore, they are intended not only for new oper-

ating personnel to be instructed in its use, but also for use

as a reference manual. They help to avoid risks and also to

reduce repair costs and down-times. Furthermore, reliabil-

ity and service life of the equipment will be increased. For

these reasons, these operating instructions must always

be kept available near the device.

Priortorstuse,pleaseperusethechapter“Foryoursafety”

in order to be prepared for any possible dangerous situa-

tions. To do this during work would be too late.

The basic principles are:

Judicious and careful work provides best protection

against accidents!

Operational safety and readiness for use of the device de-

pend not only on your capabilities, but also on the care and

maintenance given to the Variotherm plus. For this reason,

regular cleaning and service work are a must. Major main-

tenance and repair work may be carried out only by expert

personnel authorized by ATMOS. In case of repairs, you

should insist that only original spare parts are used. You will

then have the warranty that operational safety, readiness for

work, and the value of your device will be preserved.

• The product Variotherm plus bears CE marking CE 0124

according to EU Council Directive 93/42/EEC concerning

medical devices and meets the basic requirements of

Annex I to this directive.

• The product Variotherm plus complies with all applicable

requirements of Directive 2011/65/EU restricting the use

of certain hazardous substances in electrical and elec-

tronicequipment(“RoHS”).

• The declarations of conformity and our general standard

terms and conditions can be obtained on our website at

www.atmosmed.com.

• The quality management system applied at ATMOS has

beencertiedaccordingtointernationalstandard

EN 13485.

• Reprints—also in extracts—only with permission in writ-

ten form by ATMOS.

Abbreviations/symbols contained in these operating

instructions:

• Indicates a list

- Subdivision of a list/activity

The recommended sequence must be followed in each

case!

)Indicates particularly important advice!

ªDescribestheeectofanactivity

ATMOS

MedizinTechnikGmbH&Co.KG

Ludwig-Kegel-Str.16

79853 Lenzkirch

Germany

Telephone: + 49 7653 689-0

Fax:

+ 49 7653 689-190

+497653689-393(ServiceCenter)

E-mail: [email protected]

Internet: www.atmosmed.com

4

1.0 Introduction

1.2 Intended use

Product name: Variotherm plus

Main functions: Stimulation of the vestibular organ

Irrigation of the external auditory

canal

Intended purpose: Stimulation of the vestibular organ

Irrigation of the external auditory

canal

Intended users /

User prole:

Doctors and medical specialists

Intended patient

target group:

Patients of all ages without

restrictions

Medical conditions

to be diagnosed,

treated or moni-

tored:

Vertigo due to a disorder of the

vestibular organ

Hearinglossduetocerumeninthe

ear canal

Application organ: External auditory canal to eardrum

Application peri-

od:

Transient(<60min)

Application envi-

ronment:

Outpatient medical facilities, e.g.,

ENT practices, hospital outpatient

departments, medical care centers

Patient selection

criteria:

Patients with intact, physiological

eardrum and external auditory

canal

Indications: Dierentialdiagnosticsforvertigo

Hearinglossthroughimpacted

cerumen

Medical contra-

indications:

Pathological eardrum

Other contra-

indications:

Pathological external auditory canal

Warnings: N/A

The product is: active

Sterility/specic

microbial

status:

Non-sterile

Single use product

/ reprocessing:

Not a single-use product. Repro-

cessing according to instructions

for use.

1.3 Function

• Operating the main switch on the treatment unit automat-

ically activates the thermal process for reducing bacterial

count(seesection4.5.1).Then,automaticchangeto

energy saving mode.

• When removing the irrigation handle from its holder, au-

tomaticchangetotheirrigationmode.Here,theauditory

canal can be rinsed with water warmed up to 37 °C and a

owofatleast400ml/min.

• Possibility to switch to the stimulation mode for stimulat-

ingthevestibularorganwithareducedowofwater.

The Variotherm plus is equipped with a timer for

preselecting the stimulation duration.

1.4 Explanation of symbols

Follow operating instructions

According to ISO 7000/0434

DIN 30600/1008, IEC 348

Type B applied part

Fuse according to IEC 417/5016,

DIN 30600/0186

°C Temperature in degree centigrade

sTimer adjustment in seconds

Start

Stop

Timer

Cold stimulation level

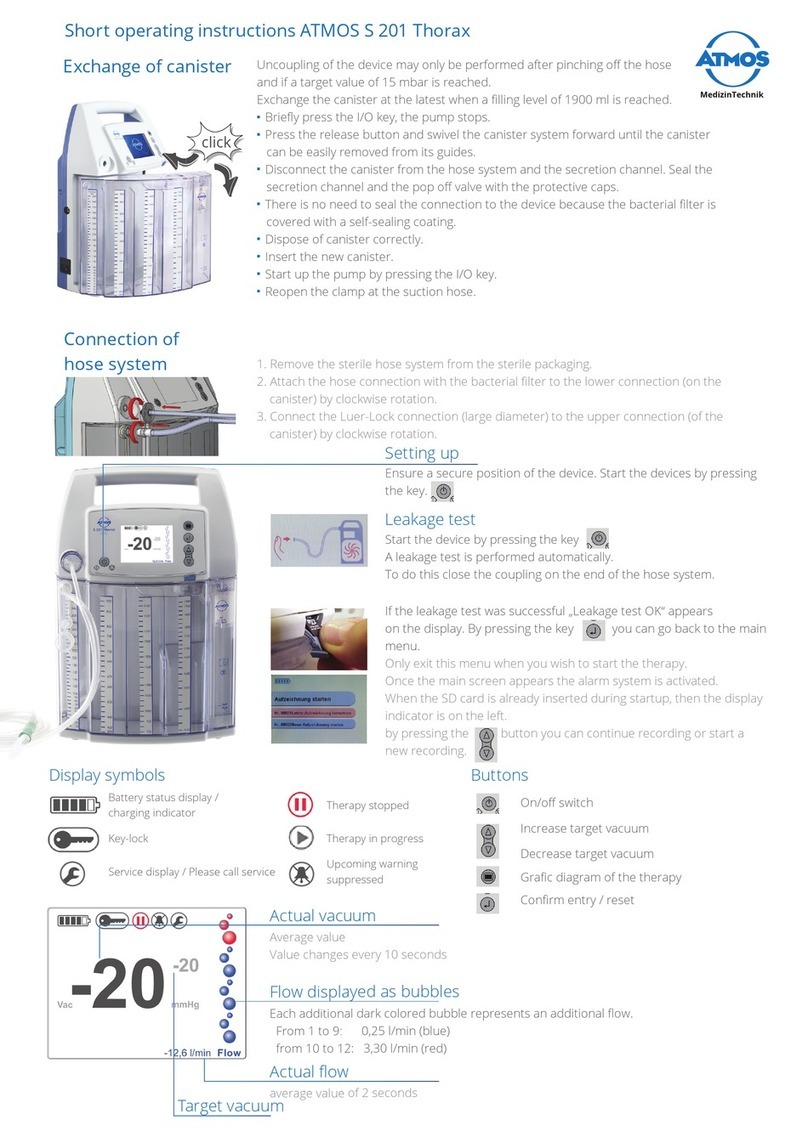

Warm stimulation level

37 °C Irrigation level (water at a temperature value

of37°C)

•HeatingON

•HeatingOFF(energysavingmode)

Control output for connecting a nystagmo-

graph (graphical recorder as per DIN 30600,

IEC4175192)

Equipotential connection

DIN 30600 495, ISO 417 5021

Connection for waste water

Connection for water

Low Reducedow(forstimulationofthe

vestibularorgan)

High Highow(forrinsingtheauditorycanal)

5

2.0 For your safety

• The Variotherm plus is produced according to IEC 601 /

EN 60601 and listed in the following classes:

- VDE Class of protection 1

- ClassIIa(93/42/EEC).

• WARNING: In order to avoid the danger of an elec-

tric shock, this device should only be connected to an

earthed power supply.

• The device must be installed by a specialist authorized by

ATMOS(seesection3.3).

• The Variotherm plus may only be used under the supervi-

sionofskilledstawhohavebeenauthorizedbyATMOS

andtrainedinitsoperation(IEC601-1/EN60601-1).

• The mains voltage indicated on the type plate must corre-

spond to the values of the supply network.

• Make sure prior to every application of the equipment that

it is technically safe and in proper condition. Damaged

cables must be replaced immediately!

• Correctcongurationinassemblyofcountry-specic

connections:

- green/yellow:protectiveconductor(PE)

- blue:neutralconductor(N)

- blackorbrown:phase(L)

• Itisessentialthatthecountry-specicrequirementsfor

connection of medical equipment to the public drinking

water supply are considered. When in doubt, please

contact your local ATMOS partner.

• The control panel must be clearly visible and accessible

fortheuser.Ensuresucientstabilityoftheinstallation

surface.

• In order to safely disconnect the device from the mains

power supply, the power cable must be removed from the

IEC power connector of the Variotherm plus!

)In the thermal process for reducing bacterial count, hot

water is conducted through the irrigation handle. Please

do not take the handle from its holder or spray water!

)Metal parts can be hot!

)Prior to spraying, the water temperature must be checked

bytheuser(display)!

• Switchothemainswitchafternishingworkintheprac-

tice and close the water valve of the water supply.

• The Variotherm plus may be operated only in rooms used

for medical purposes, but not in areas subject to explo-

sion hazards and not in oxygen-rich environments.

• All additional equipment that is connected to the analog

and digital interfaces of the device must meet the require-

mentsofrelevantENspecications(e.g.,EN60950for

data processing equipment and EN 60601 for electrical

medicalequipment).Inaddition,congurationsmust

satisfysystemspecicationEN60601-1-1.Whenaddi-

tional equipment is connected to the signal input or signal

output section on the device, the person carrying out the

connectionisdeemed“asystemcongurationoperator”

and as such is responsible for meeting the requirements

ofsystemspecicationEN60601-1-1.Ifyouhaveany

questions, please contact your local specialist supplier or

ATMOS Technical Service.

• The irrigation jet must not get into contact with contami-

nated material.

• Only use the warm water jet when a hose tip is installed!

• Take caution to avoid injury to the eardrum when insert-

ing the water jet!

• For hygienic reasons, hose tips must be changed after

each patient. This also prevents retrograde contamination

of the warm water system.

• Use only for irrigation of the auditory canal!

• ATMOS is not liable for personal injury and damage to

property if

- no original ATMOS parts are being used,

- the advice for use in these operating instructions is

not being observed,

- assembly, new settings, alterations, extensions, and

repairs have been carried out by personnel not au-

thorized by ATMOS.

• Please note:

A medical isolation transformer with earth leakage

monitor or any similar safety system acc. to EN 60601-

1 is required if several devices are connected over one

common power supply. The transformer must correspond

to the power consumption of all the devices to be con-

nected.

• After switching on the device or at least once a week,

theowratemustbecheckedusingavolumemeasuring

funnel. The quantity of 500 ml/min may not be exceeded.

The water jet has to be straight.

6

2.0 For your safety

2.1 Important instructions for the maintenance of the hygiene status of warm water

irrigation units

Forlooseningcerumenintheauditorymeatusandforstimulatingthevestibularorgan,ATMOSoersthewarmwaterunits

Hygrothermplus(37°C)andVariothermplus(20°C‒47°C).

These units heat the drinking water that comes from the household connection to the preselected temperature. The operating in-

structionsmustbefollowed,orotherwisetheincreasednumberofpathogensintherinsewatercanaectthehealthofsensitive

patients.

Requirement for taking into use

ThewaterprovidedbythehouseholdconnectionmustatleastmeettheWHOguidelinesorthecountry-specicguidelines

for drinking water.

Connection

Freshwatermustowthroughthewallconnectionforaperiodofapprox.1minutepriortotheunitbeingconnected.*

Ensure that the installation is hygienically carried out! Disinfect the threaded connections with 70% alcohol before screwing

themintoplace.*

Weardisposablegloveswhencarryingoutmaintenanceworkonpartsthatcomeintocontactwiththewater.*

Carryoutthermalcleaningatleast3timesbeforeinitialoperation.*

*ThisworkiscarriedoutbytheATMOSservicetechnician.

Running operation

Before beginning everyday practice operations, switch on the unit and await the thermal cleaning process.

Afterthedevicehasbeenidleforalongperiodoftime(weekend,duringholidays,etc.),thethermalcleaningprocessmust

be initiated and repeated.

Werecommendthatthedevicebeswitchedoandonevery2hours,butnolaterthan4hours,tostartthethermalcleaning

mode.

Contactparts,e.g.,hosetips,mustbereplacedaftereverypatient(preventionofretrogradecontamination).

Before every use, spray water and check the temperature.

Service

Observehygienewhenchangingthesuspendedparticlelter(seecommissioning)(disposeoflterandcarefullycleanthe

lterglass).Ensurethatnocontactismadewithcontaminatedparts.

Carry out thermal cleaning after each service.

We recommend having regular germ count measurements of the water taken at the inlet and outlet of the unit. In the case of

acomplaint,datameasurementsmustprovewhetherthecontaminantsare“waterbacteria”or“skinbacteria.”

7

3.0 Setting up and starting up

3.1 Scope of supply

Quantity

1 Variotherm plus basic unit

1 Irrigation handle

1 Double-barrelled hose

3Jetconnectionshort,straight(80mm)

1 Splash guard

1 Rubber bushing for splash guard

2 Three-hole gasket

1Hosetipsforjetconnection(30pcs)

1 G3/4i-G1/4a-screwing (water tap G3/4 on

lterG1/4)

1 Cap nut G3/4

1Waterltercomplete

2Gasket(f.G1/4a)13x18x1

1G1/4a-G3/4a-reducer(lterG1/4on

waterhoseG3/4)

1 Water supply hose G3/4i, L = 3 m

1 Waste water hose G1/4i, L = 3 m

2Gasket(f.G1/4i)10x15x1

1 Cardboard box 455 x 340 x 250 mm

1 Padding for cardboard box

1 Operating Instructions

8

3.0 Setting up and starting up

3.2 Illustrations

Variotherm plus

3 0 3 7

—

11

3

[[

030 4

4

[

Fig. 1. Front view

1Main switch

2KeyswitchforheatingON/OFF(energysaving

mode)

3Coding switch for warm stimulation level

4Coding switch for cold stimulation level

5Coding switch for stimulation time

6Keyswitchforselectingtheirrigationlevel(37°C)

7Keyswitchforselectingthewarmstimulationlevel

(e.g.,44°C)

8Keyswitchforselectingthecoldstimulationlevel

(e.g.,30°C)

9Keyswitchforstart/stopofthestimulation

10Temperaturedisplay(two-gurenumber,increment

of1°C),actualvalueindication

11Displayofstimulationtime(two-gurenumber,incre-

mentof1s)

9

Fig. 3. Side view

1Holderforhandle

2Connection for double-barrelled hose

3Connectionforwastewaterhose*

4Connection for water supply hose

3.0 Setting up and starting up

F 14 AH

Fig. 2. Rear view

1Type plate

2Control output for controlling a nystagmograph

3Device socket with fuse compartment

4Equipotential bonding connection

p = +2000...+6000 hPa

t = +7...+19.5 °C

Press down ring

*

10

3.0 Setting up and starting up

Fig. 4. Irrigation handle

1Handle

2Connection for double-barrelled hose

3Three-hole gasket

4Adjusting screw

5Set screw

6Valve plunger

7Jet connection

8Splash guard

9Cap

10 Double-barrelled hose

The sprayer nozzle must be changed after each

patient.

!

11

3.0 Setting up and starting up

Fig. 5.

3.3 Connections

3.3.1 Electrical connection

• According to the directions of VDE 0107 and VDE 0100,

medically used rooms have to be equipped with a leak-

agecurrentprotectivecircuit(FIprotectivecircuit)with

a nominal leakage current of < 0.03 A. Installation must

correspond with VDE 0107.

• Connect the power cable to the socket on the unit (,

Fig.2).

• Insert the power plug in a correctly installed socket with

earthing contact.

3.3.2 Connecting a nystagmograph

• WhencontrollinganENG(electro-nystagmograph)ora

CNG(computer-nystagmograph)atoutput(,Fig.2),

please connect only recording equipment approved by

ATMOS. Connecting cable available from ATMOS (see

chapter8.0).

• At the end of the stimulation time, a trigger signal for a

nystagmograph is available at the rear 3-pole DIN socket.

This outlet is an electrically isolated photo transistor.

The emitter connection that has to be connected to the

ground line of the trigger inlet on the nystagmograph is

attached to pin 3. The open-collector connection is locat-

ed on pin 1 and is to be connected to the positive supply

voltage(+5Vor+12V)bymeansofapull-upresistance.

The maximum collector voltage of the transistor may not

exceed 80 MA.

3.3.3 Equipotential bonding conductor connec-

tion

• Connection for potential equalization (,Fig.2).Con-

nectingcableavailablefromATMOS(seechapter8.0).

12

3.3.4 Water connection

• Local requirements:

- Water tap with G3/4" external thread.

- Drinking water!

- Input water pressure: +2000...+6000 hPa.

- Feedtemperature:+7...+19.5°C(recommended),

but at least 0.5 °C below the required lowest cold

stimulation value.

- Drainagettings(REF502.0880.0)

• Connection to water supply and waste water:

- Therearecountry-specicregulationsfortheinstal-

lation to be considered when the unit is connected

to the public water supply. To comply with the rules

according to EN 1717, an unpressurized water sepa-

rationwithoverowisrequired.

Therefore, ATMOS recommends installing the water

separationunitATMOSAquaClean(REF502.1200.0)

between the water supply and the device in order to

meet the connection requirements according to EN

1717.

- Prior to connecting the unit to the water supply, the

feedlinemustbeushedcleanbyopeningthewater

tapforaminuteandallowingfreeowofthetap

water.

- Connectthelterunittothewatertapbymeansof

adaptor and gasket.

- Insert the gaskets in the cap nuts of the water supply

hose.

- Jointhenutswiththelterconnectionandtheunit

connection (,Fig.3).

- Insert the gaskets in the cap nuts of the waste water

hose.

- Join the nuts with the unit connection (,Fig.3)and

thedrainagettings.

- Thereisnospecialcalcicationsafetydeviceinte-

grated in the water system. Such a system is to be

connected when the respective drinking water is of

hardness grade 3 (14‒21°dHor2.5‒3.8 mmol/l =

hardwater)andofhardnessgrade4(from21°dHor

from3.8mmol/l=veryhardwater).

Please contact your local water supplier and/or

plumber.

Water

hardness

Millimole per

liter

°dH

1(soft) ≤1.3 ≤7.3 Calcication

protection system

is not required

2 (medi-

um)

1.3 to 2.5 7.3 to 14

3(hard) 2.5 to 3.8 14 to 21.3 Calcication

protection system

is required

4 (very

hard)

> 3.8 > 21.3

Close the water tap when the unit is not in use!

!

3.0 Setting up and starting up

3.3.5 Connection of the irrigation handle

• Insert a three-hole gasket (,Fig.4)inthedouble

barrelled hose (,Fig.4)andscrewitontheunitcon-

nection (,Fig.3).

)Use only three-hole gaskets or otherwise the unit will not

function correctly!

• Insert a three-hole gasket in the irrigation handle and

screw it on the free end of the double-barrelled hose.

• Open the water tap. Check whether all connections are

tight.

3.4 Starting up

• Insert the handle in its holder; the jet must point to re-

verse side of the unit.

• Switch on the unit (,Fig.1).

• Automaticdisplaytestwithdigitalnumbers“88”and

acoustic warning signal.

• Automatic activation of the thermal process will begin for

reducing bacterial count. Duration: 5 min.

• Automaticchangetotheirrigationmode(37°C).

• When the irrigation mode is not being used (handle is

notremovedfromitsholder),theunitchangestoenergy

saving mode after 5 min.

13

4.0 Operation

Before switching on the unit, make sure that the handle is in

itsholder(jetmustpointtoreversesideoftheunit).

4.1 Adjusting temperatures

• Number of temperature levels: 3

- Onelevelxedto37°Cirrigationtemperature

- Two variable temperature levels

20 °C ‒47 °C

48 °C and 49 °C only for testing purposes

• Temperature setting by coding switch (, ,Fig.1)

- Leftswitch:foradjustingthe“ten”partition

- Rightswitch:foradjustingthe“one”partition

ªLowerkeys(+):temperatureincrease

ªUpperkeys(-):temperaturedecrease

• Standard settings:

- Levelforirrigationmode:37°Cxed

- Level for cold stimulation: 30 °C

- Level for warm stimulation: 44 °C

4.2 Selecting temperature levels

• After operating the main power switch, the automatic

activation of the thermal process begins for reducing

bacterial count, followed by the automatic activation of

thetemperaturelevel“irrigationmode”(37°C).

• For selecting the desired temperature level, use the

respective key (, , ,Fig.1).

ªDisplay of the active level by LEDs.

ªDisplayofthewatertemperature(currentvalue)in°C.

4.3 Adjusting stimulation time

• By means of coding switch (,Fig.1).

4.4 Adjusting ow quantity

• Prior to stimulation, turn the set screw (,Fig.6)tothe

postition "Low".

• 2 adjusting possibilities:

- High:owquantityforearirrigation

- Low:owquantityforstimulationofthevestibular

organ

Prior to ear irrigation, turn the set screw to the postition

"High",pushitintothehandle,andthenadjustitbyscrew-

ing it in further.

Forneadjustmentoftheow,turntheadjustingscrew(,

Fig.6)inorout.

)Periodicallycheckthewaterowforthestimulationofthe

vestibular organ and readjust if necessary.

Fig. 6. Irrigation handle

1Set screw

2Adjusting screw

14

4.0 Operation

4.5 Description of operating modes

4.5.1 Thermal process for reducing bacterial

count

Purpose:

Reduction of bacteria count in the warm water circuit to

prevent or clear a contaminated system.

Activation:

Occurs each time the unit is switched on.

• Condition for starting the correct thermal process for

reducing bacterial count:

- The irrigation handle must be inserted in the holder

ontheside(jetpointingtoreversesideoftheunit).

ªIf not, a warning signal is given (warning also sounds

when the handle is removed during the thermal clean-

ingprocedure).

ªAdditionally,theerrorcode“F0”isshown(disappears

whenhandleisreturned).

)In the thermal process for reducing bacterial count, hot

water is conducted through the irrigation handle. Please

do not take the handle from its holder or spray water!

)Metal parts of the irrigation handle and of the double-

barrelled hose will be hot! Please do not touch metal

parts during the thermal cleaning procedure!

• During the thermal process for reducing bacterial count,

thetemperaturedisplayshowsa“d”ontherstseg-

mentandtheremainingtime(inminutes)onthesecond

segment.

• After cooling down to 37 °C, the unit will automatically

switch to irrigation mode.

4.5.2 Irrigation mode

Purpose:

Rinsing of the auditory canal.

Properties:

• Temperature: 37 °C, permanently set.

• Positionofthesetscrew:High(seeFig.6,page13).

Activation:

• Automatically after completion of thermal cleaning proce-

dure and taking out the handle or by key (,Fig.1).

• When the irrigation mode is not being used (handle re-

mainsinholder),theVariothermpluschangestoenergy

saving mode after 5 min.

• Reactivation of the irrigation mode by taking the handle

out of the holder or activating a key on the temperature

control unit.

• If the 37 °C push button is pressed repeatedly, the heat-

ingisswitchedo.

ªWater with feed temperature is available.

4.5.3 Stimulation mode

Purpose:

Stimulation of the vestibular organ.

Properties:

• Temperature: corresponds to the preselected cold or

warm stimulation level.

• Positionofthesetscrew:Low(seeFig.6,page13).

• Duration: as preset by the timer.

Activation:

• Initially select the type of stimulation by activating either

the warm stimulation or cold stimulation key (, , Fig.

1)(seesection4.1forpresettingoftemperature).

ªWaterwiththepresettemperaturevalueowstothe

handle.

• Wait for 20 seconds.

• Operatethe“timerstartˮkey.

• Preparation for stimulation:

- Operate unit 15 seconds in holding position so that

the jet can be positioned correctly in the auditory

canal.

)During this period, the water is directed via the handle

into the drain in order to guarantee optimum temperature

stability;opticalindicationbytheashinggureinthe

temperature display.

Do not start stimulation by operating the release lever on

the handle until you hear the audible signal!

• Carrying out the thermostimulation via the set screw on

the handle (,Fig.4).

• At the end of the stimulation period, a control signal for a

recording unit is issued at the nystagmograph output.

• After stimulation is completed, the unit remains in a hold-

ing position for 15 seconds so that the handle may be

removed from the auditory canal.

ªDuringthistime,waterowsintothedrain;again,an

opticalindicationismadebyashingtemperature

value.

• Repeatedactivationofthe“timerstartˮkeystopstimer

operation.

• Second activation of the currently active key deactivates

the corresponding level.

ªHeatingisswitchedocompletely.

ªStimulationwithcoldwater(feedtemperature).

4.5.4 Energy saving mode

Purpose:

Reduction of energy consumption.

Activation:

• Activationofkey“heatingon/o”(,Fig.1).

ªHeatingisswitchedo.

• Afterveminutesofnon-useoftheunit.

15

5.0 Cleaning and care

5.1 General information on cleaning and

disinfection

The jet connection, which comes into direct contact

with the patient, must be disinfected after each use.

The hose tips must be changed after each use.

The surfaces of the Variotherm plus resist most common

surface disinfectants.

However, do not use

• disinfectants that contain concentrated organic or inor-

ganic acids as they could cause corrosion damage.

• disinfectants containing chloramides, phenol derivatives,

or anionic surfactants, as these may cause stress cracks

in the material used for the housing of the unit.

You may also use disinfectant sprays or disinfectant wipes

for cleaning and disinfection.

)Set main switch of the device to OFF prior to cleaning

and disinfection!

Wipe the unit surface with a cloth moistened with a cleaning

or disinfecting solution. Take care that no liquid penetrates

the device. The cleaning agents and disinfectants listed in

section 5.2 are all suitable.

)Spilled liquid must immediately be wiped dry.

)Always observe the instructions for use by the manu-

facturer of the disinfectants, including all concentration

specications.

)The described actions relating to cleaning and disinfec-

tion or sterilization do not substitute the relevant instruc-

tions which must be adhered to prior to operation.

5.2 Recommended disinfectants

Manual disinfection of instruments

Disinfectant Ingredients in 100 g Manufacturer

Korsolexbasic

(Applicationconcentrate)

glutaral 15.2 g BodeChemie,Hamburg

(ethylenedioxy)dimethanol 19.7 g

surfactants, salts, corrosion inhibitors

Sekusept aktiv

(Applicationconcentrate)

sodiumpercarbonate, phosphonates Ecolab, Düsseldorf

nonionic surfactants

Gigasept FF new

(Applicationconcentrate)

succindialdehyde 11.0 g Schülke&Mayr,

Norderstedt

dimethoxytetrahydrofurane 3.0 g

corrosion inhibitors

nonionic surfactants and perfumes

Automatic disinfection of instruments

Disinfectant Ingredients in 100 g Manufacturer

Neodisher MediClean

forte

(Applicationconcentrate)

NTA 5–15 g Dr.Weigert,Hamburg

nonionic surfactants < 5 g

enzymes

preserving agents

Surfaces

Disinfectant Ingredients in 100 g Manufacturer

Dismozon pur

(Granulate)

End of product 12/2014

magnesium monoperoxyphthalate hexahydrate 80 g BodeChemie,Hamburg

Dismozon plus

(Granulate)

magnesium monoperoxyphthalate hexahydrate 95.8 g BodeChemie,Hamburg

Green&CleanSK

(Applicationconcentrate)

Alkyl dimethyl benzyl ammonium chloride < 1 g Metasys,Rum(Austria)

Dialkyldimethylammoniumchloride

Alkyl dimethyl ethyl benzyl ammonium chloride

Perform Pentapotassiumbis(peroxymonosulphate)-bis(sulphate) 45.0 g Schülke&Mayr,

Norderstedt

When using disinfectants containing aldehyde and amine on the same object, color changes may occur.

16

5.0 Cleaning and care

5.3 Cleaning method for handle with jet connection for water irrigation tip

TheATMOSdevicesVariothermplusandHygrothermplusareproperlyusedwithdisposablehosetips.Thesehosetipsmust

be disposed of after each application to the patient.

When using the hose tips, ATMOS recommends reprocessing according to the cleaning and disinfection plan below.

What How

Details

When Who

C D S

After each

application

Daily

Weekly

Monthly

Qualiedandtrained

stawhoarefamiliar

with reprocessing

(pleasellinthe

responsible person

-> use a water-based

overheadmarker)

Parts to be reprocessed Cleaning Disinfection Sterilization

Ear irrigation / Thermal nystagmus stimulation

Handle X X3Wipe cleaning and disinfection X

Jet connection X X2,4,5.6 Cleaning and disinfection (manual or

automatic) X

Splash guard X X2,4,5 Cleaning and disinfection (manual or

automatic) X

Hosetip(dis-

posable) Change after each application X

Rinsing attach-

ment X X2,4,5 Cleaning and disinfection (manual or

automatic) X

Hygienelter See operating instructions for hygiene

lter X

Recommended disinfectants

3)Surface disinfection for coat-

ed surfaces:

Other surfaces: 4)Manual disinfection of instru-

ments:

5)Automatic disinfection of instruments:

• Green&CleanSK(ATMOS)

• Dismozon®plus(BodeChemie)

• Kohrsolin®FF(BodeChemie)

• Perform®(Schülke&Mayr)

• Terralin®Protect(Schülke&Mayr)

• Dismozon®plus(BodeChemie)

• Kohrsolin®FF(BodeChemie)

• Bacillocid®rasant(BodeChemie)

• Mikrobac®forte(BodeChemie)

• Perform®(Schülke&Mayr)

• Terralin®Protect(Schülke&Mayr)

• Surface disinfectant FD 312 (Dürr

Dental)

• QuickdisinfectionB30(Orochemie)

• Korsolex®AF(BodeChemie)

• Korsolex®basic(BodeChemie)

• Korsolex®plus(BodeChemie)

• Korsolex®extra(BodeChemie)

• neodisher®SeptoMED(Dr.Weigert)

• neodisher®Septo3000(Dr.Weigert)

• Sekusept®PLUS(Ecolab)

• Sekusept®aktiv(Ecolab)

• Gigasept®InstruAF(Schülke&Mayr)

• Gigazyme®(Schülke&Mayr)

• GigaseptFFneu(Schülke&Mayr)

• Dismoclean®21clean(BodeChemie)

• Dismoclean®24Vario(BodeChemie)

• Dismoclean®28alkaone(BodeChemie)

• Dismoclean®twinbasic/twinzyme(BodeChemie)

• neodisher®FA(Dr.Weigert)

• neodisher®FAforte(Dr.Weigert)

• neodisher®MediCleanforte(Dr.Weigert)

• Thermosept®alkacleanforte(Schülke&Mayr)

• Thermosept®RKN-zym(Schülke&Mayr)

For concentrations, contact time, temperature and material compatibility, please see the relevant information from the manufacturer.

Important information

Wipecleaninganddisinfection:Allsurfacesmustbewipedwithaclean(disposable)wipewhichisdampenedwithdisinfectantsolution;the

entire surface must be wiped thoroughly and may not be dried afterwards.

1) Please observe the manufacturer’s instructions for use.

2) Preferred: machine cleaning and disinfection in a washer disinfector

6)Material dimensionally stable at 134 °C

17

6.0 Maintenance and service

• Decalcicationandchangingoflter(seesections6.1,6.2)shouldbecarriedoutimmediatelybytheuserwhenrequired.

Maintenance, repairs, and periodic tests may only be carried out by persons who have the appropriate technical knowledge and

are familiar with the product. To carry out these measures, the person must have the necessary test devices and original spare

parts.

ATMOS recommends: Work should be carried out by an authorized ATMOS service partner. This ensures that repairs and test-

ingarecarriedoutprofessionally,originalsparepartsareused,andwarrantyclaimsremainunaected.

• Carryoutaninspectionaccordingtothemanufacturer’sspecicationsevery12months.

• Please observe the corresponding service instructions.

6.1 Decalcication

Ifthetapwaterintheareawheretheunitisusedisknownformineralprecipitation,preventivedecalcicationshouldbecarried

out:

• Close water tap.

• Ifapplicable,dismantlelterwhenmountedverticallyonwatertap.

• Unscrewscrewedglassoflter.

• Fillglasswithapprox.100mlofdecalcieronacetic,citric,orlacticacidbasis(e.g.,CitrosterilbyFresenius).

• Screw glass on again.

• Installlterverticallyagain,ifapplicable.

• Open water tap again.

• Switch on the device.

ªDecalcicationtakesplaceautomaticallyinthethermalprocessforreducingbacterialcount.Aftertheunithasbeeninthis

modefor5minutes,thewaterpassageshavebeendecalciedandcleanedandalsosucientlyushed.TheVariotherm

plusisagainfullyreadyforoperation.Whenwaterpassagesareheavilycalcied,amodiedproceduremaybecome

necessaryhavingaprolongedreactionperiodforthedecalcier.

Recommendation:Calcicationsafetydevice(REF502.0995.0).

6.2 Replacement of lter

• Whentheltercartridgeisverydirty(darkcolor),thelter

cartridge is to be changed as follows:

- Close water supply tap.

- Switchonunittoreducepressureinthelterbody.

- Switchounitafter“F1”appears.

- Unscrew plexiglass cup (,Fig.7)fromlterbody

(,Fig.7)byturningcounterclockwise.

- Removeltercartridge(,Fig.7)andreplacewitha

new one.

• Thelterelementmustnotcomeintocontactwith

contaminated objects in order to prevent the ingress of

germs into the water system.

Filter body

Filter cartridge

Sealing ring

Plexiglass cup

Fig. 7. Water lter

6.3 Sending in the device

• Remove and properly dispose of consumables.

• Clean and disinfect the product and accessories according to the operating instructions.

• Place any used accessories with the product.

• FillintheformQD434“Deliverycomplaint/returnshipment”andtherespectiveDecontamination certicate.

)This form is enclosed with each delivery and can be found at www.atmosmed.com.

• The device must be well padded and packed in suitable packaging.

• PlaceformQD434“Deliverycomplaint/returnshipment”andtherespectiveDecontamination certicate in an envelope.

• Axtheenvelopetotheoutsideofthepackage.

• Send the product to ATMOS or to your dealer.

18

7.0 Troubleshooting

Error in temperature display

“F0” Handleisnotinitsholder • Insert handle in its holder to allow thermal process for reducing

bacterial count to start (jet connection must point to the back of

theunit).

• Replacehandle(REF502.0963.0).

“F1” Nowater(waterpressure<0.5bar) • Check whether the water supply delivers a pressure of at least

2bar(didyouopenthewatertap?).

• Filter clogged?

“F2” -5 V is missing (supply voltage on the control-

lerboard)

• Informtheservicesta.

“F3” Break of the safety NTC • Informtheservicesta.

“F4” Safety switching does not react (49 °C com-

parator)

• Havethesafetyswitching(temperaturecontroller)checkedbythe

servicesta.

“F5” Break of the regulating NTC • Informtheservicesta.

“F6” Dierentswitchsettingsinthehandleholder • Handlemustbecorrectlyinsertedinitsholder.

• Otherwise,informtheservicesta.

“F7” Temperaturetoohigh(>48°C);displayonlyin

the stimulation and irrigation mode but not in

the thermal cleaning procedure

• Check whether temperature setting is too high. If necessary,

adjust desired temperature to a value of < 48 °C by means of the

coding switches.

• Informtheservicesta.

“F8” Short-circuit of the regulating NTC • HavetemperaturefeeleroftheregulatingNTCcheckedbythe

servicesta.

“F9” No heating performance (excess temperature

switch,def.semi-conductorrelayorregulator)

• Informtheservicesta(internalexcesstemperatureswitchmight

havereleased).

)Iferrorscannotbecorrectedwiththeassistanceofthetroubleshootinglist,pleaseinformtheservicestaorsendinthe

device for repair. Do not start any attempts to repair the unit yourself!

19

8.0 Accessories and spare parts

8.1 Accessories

Description .....................................................................................................................................................REF

Calcicationsafetydevice................................................................................................................................502.0995.0

Jetconnectionextralong,straight(110mm) ...................................................................................................508.0429.0

Rinsingconnection(Teon)forstimulatingthevestibularorgan......................................................................501.0355.0

Extension of supply hose G3/4a-G3/4i, L =1,5 m.............................................................................................501.0315.6

Wastewaterhose,speciallength,G1/4a-G1/4a(pleaseindicatedesiredlength)...........................................502.0881.1

DrainagettingsastoDIN1988 ......................................................................................................................502.0880.0

Connecting cable for a nystagmograph ...........................................................................................................502.0850.0

Connecting cable for the equipotential compensation, L = 5m ........................................................................008.0596.0

8.2 Spare parts

Description .....................................................................................................................................................REF

Variothermplus,basicunit,220-240VAC,50/60Hz ......................................................................................502.0900.0

Variothermplus,basicunit,110-127VAC,50/60Hz.......................................................................................502.0900.1

Irrigation handle 4+ ..........................................................................................................................................502.0963.0

Double-barrelled hose......................................................................................................................................510.0412.0

Jetconnectionshort,straight(80mm)..............................................................................................................508.0427.0

Splash guard ....................................................................................................................................................501.0331.0

Rubber bush for splash guard..........................................................................................................................501.0331.1

Throttlingnozzle0.5mm(150ml/min).............................................................................................................502.0946.0

Throttlingnozzle0.7mm(250ml/min).............................................................................................................502.0946.1

Three-hole gasket ............................................................................................................................................501.0320.0

Hosetipsforjetconnection(30pcs)................................................................................................................502.0844.0

G3/4a-G3/4i, L =3 m.........................................................................................................................................502.0768.1

CapnutG3/4(tobeincludedinorder).............................................................................................................052.0035.1

Waterltercomplete ........................................................................................................................................502.0890.0

Filterelementforwaterlter.............................................................................................................................502.0891.0

Gasket(forG1/4a)13x18x1.............................................................................................................................055.0018.0

G1/4a-G3/4a-reducer(lterG1/4onwaterhoseG3/4)....................................................................................502.0724.1

Supply hose with connection G3/4i, L = 3 m ....................................................................................................501.0315.7

Waste water hose with connection G1/4, L = 3 m ............................................................................................502.0882.0

Gasket(forG1/4i)10x15x1..............................................................................................................................055.0003.0

Powercablewithprotectivecontactsocket(Germany),L=3m ......................................................................507.0859.0

PowercablewithBritishplugBS1363A(UK),L=2.5m...................................................................................008.0762.0

FuseF8A(quick-acting)250VbreakingcapacityH(1500A)........................................................................008.0767.0

Fuseforspecialvoltage(110-127VAC):F15A(quick-acting)breakingcapacity10kA008.0766.0

Front foil Variotherm plus ................................................................................................................................060.0357.0

20

9.0 Technical data

Voltage 220-240V~±10%;50/60Hz

Special voltage 100-127V~±10%;50/60Hz

Current consumption max.6.8A(220-240V~);14.8A(100-127V~)

Power consumption max. 1500 W

Connections Power connection via IEC socket; control output for a nystagmograph; equi-

potential equalization; water supply G 3/4" external thread; water drainage

G 1/4" external thread; connection for double-barrelled hose

Fuses F8A(f.220-240V~);F15A(f.110-127V~)

Stimulation time Adjustable by timer from 1 up to 99 sec.

Timer indication Indication accuracy ± 0.5 s ± ½ digit

Water temperature 20°C - 47°C

Temperature indication Indication accuracy ± 0.6°C ± ½ digit (can only be guarantee with un-

changedambientconditions)

Feed temperature of the water +7...+19.5 °C

Water quality Drinking water

Waterowintheirrigationmode

(highow)

450 ml/min: Standard unit and variant 250/450 ml/min

400 ml/min: Variant 400/400 ml/min

500 ml/min: Variant 500/500 ml/min

Waterowinthestimulationmode

(lowow)

150ml/min:Standardunit150/450ml/min(adjustable)

250ml/min:Variant250/400ml/min(adjustable)

400ml/min:Variant400/400ml/min(adjustable)

500ml/min:Variant500/500ml/min(adjustable)

Operating time Continuous operation

Operating pressure Atleast:+2000hPa(2bar);max.:+6000hPa(6bar)

Protective earth conductor resistance

Earth leakage current

Enclosure leakage current

Patient leakage current

max.0,1Ω

max. 0.5 mA

max. 0.1 mA

max. 0.1 mA

Ambient conditions

Transport / storage

-20...+50°C

5...90 % air humidity without condensation

air pressure of 700...1060 hPa

Ambient conditions

Operation

+10...+35°C

20...80 % air humidity without condensation

air pressure of 700...1060 hPa

Maximum operational altitude ≤3000m(NN)

Contamination level Class 2

Overvoltage category II

DimensionsHxWxD 14.5 x 37 x 31.5 cm

Weight Approx. 5,5 kg

Period tests Inspectionaccordingtothemanufacturersspecicationsevery12months.

Safetyclass(EN60601-1) I

Degree of protection Type B

Protection class IPX0

Furtherclassicationsaccordingtootherregu-

lations

VDEprotectionclass1(IEC601/EN60601)

ClassicationaccordingtoAppendixIXEC

Directive 93/42/EEC

Class IIa

CE marking CE 0124

Other manuals for Variotherm plus

2

Table of contents

Other Atmos Medical Equipment manuals

Atmos

Atmos Record 55 User manual

Atmos

Atmos i View 21 COLPO User manual

Atmos

Atmos S 351 User manual

Atmos

Atmos A 161 User manual

Atmos

Atmos LC 16 User manual

Atmos

Atmos LS 21 LED User manual

Atmos

Atmos S 41 Gyne User manual

Atmos

Atmos AtmoSafe User manual

Atmos

Atmos S 351 NATAL User manual

Atmos

Atmos C 11 User manual

Atmos

Atmos Scope User manual

Atmos

Atmos S 042 NPWT User manual

Atmos

Atmos Record 55 User manual

Atmos

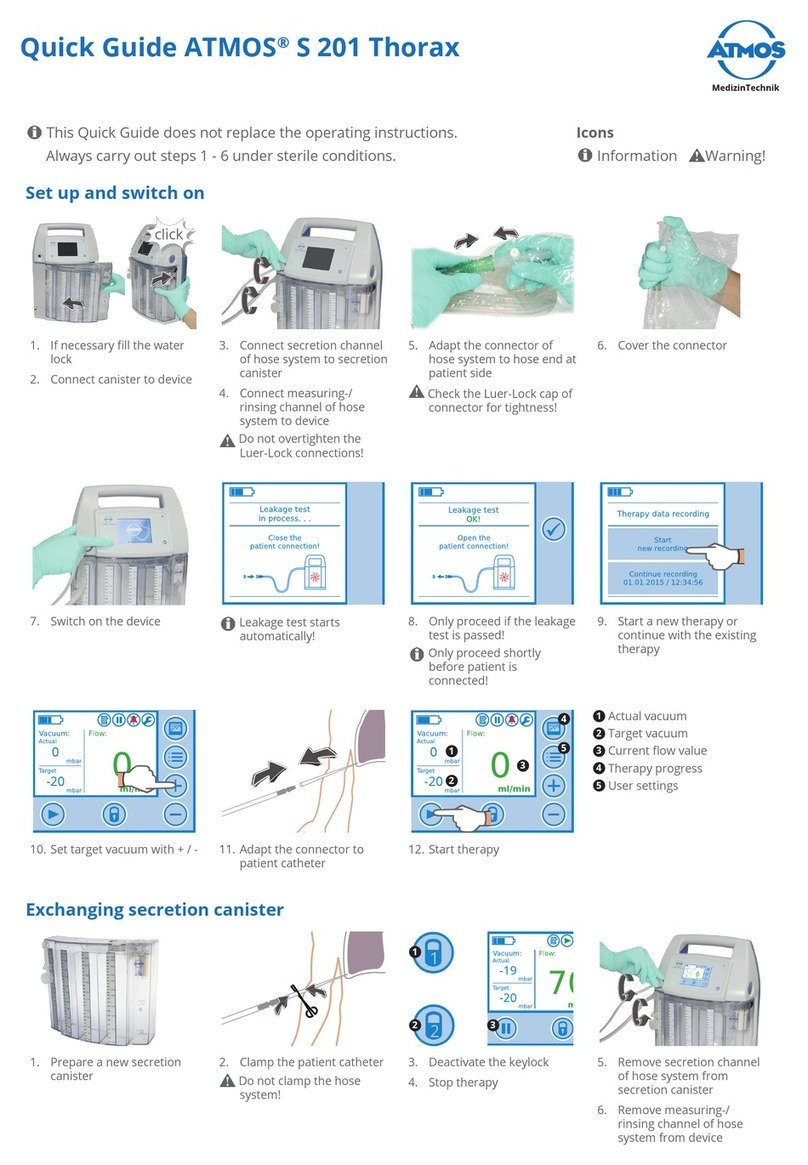

Atmos S 201 Thorax User manual

Atmos

Atmos Chair 41 Gyne User manual

Atmos

Atmos S 201 Thorax User manual

Atmos

Atmos C 31 User manual

Atmos

Atmos Record 55 DDS User manual

Atmos

Atmos S 351 User manual

Atmos

Atmos S 201 Thorax User manual