Edge trimmer with weed brush 2021 1

CONTENTS

1. FOREWORD ........................................................................................................................................ 4

Warning symbols used in this manual ...................................................................................................................................5

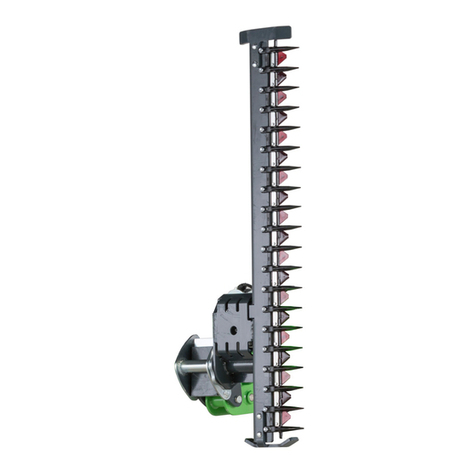

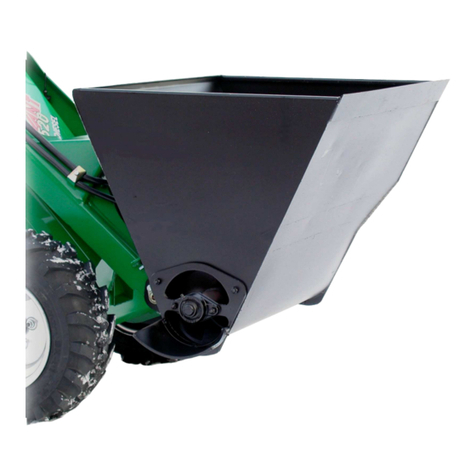

2. DESIGNED PURPOSE OF USE.......................................................................................................... 6

3. SAFETY INSTRUCTIONS FOR USING THE EDGE TRIMMER..................................................... 7

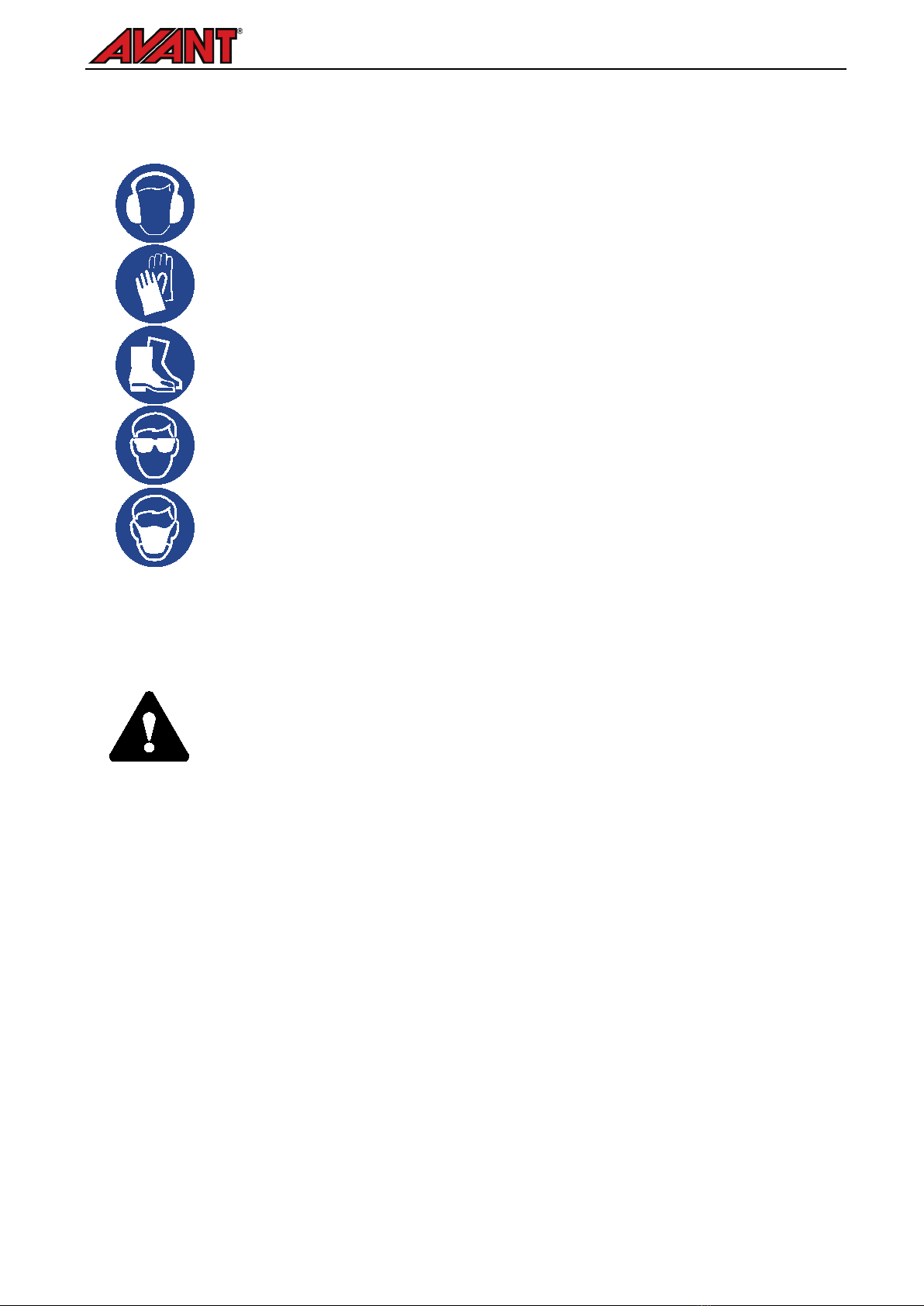

3.1 Personal protective equipment...............................................................................................................................9

3.2 Safe shutdown procedure ........................................................................................................................................9

4. TECHNICAL SPECIFICATIONS ....................................................................................................... 10

4.1 Safety labels and main components of the attachment ....................................................................................10

5. ATTACHING THE ATTACHMENT ................................................................................................. 12

5.1 Connecting and disconnecting hydraulic hoses..................................................................................................13

6. OPERATING THE ATTACHMENT .................................................................................................. 15

6.1 Safety distance.............................................................................................................................................................16

6.2 Checks before use .....................................................................................................................................................17

6.3 Operator qualification...............................................................................................................................................17

6.4 Use .................................................................................................................................................................................18

6.5 Adjustments.................................................................................................................................................................19

6.5.1 Orientation..........................................................................................................................................................19

6.5.2 Side reach adjustment.......................................................................................................................................20

6.5.3 Adjusting the cutting depth .............................................................................................................................21

6.5.4 Brush angle ..........................................................................................................................................................23

6.5.5 Support wheel.....................................................................................................................................................23

6.6 Transport position.....................................................................................................................................................24

6.7 Storage ..........................................................................................................................................................................24

7. MAINTENANCE AND SERVICE ....................................................................................................... 26

7.1 Inspection of hydraulic components .....................................................................................................................26

7.2 Cleaning the attachment...........................................................................................................................................27

7.3 Inspection of metal structures................................................................................................................................27

7.4 Lubrication ...................................................................................................................................................................27

7.5 Assembling cutting head on the left ......................................................................................................................28

7.5.1 Safety instructions for hydraulic assemblies................................................................................................28

7.5.2 Installation............................................................................................................................................................31

7.6 End of life disposal......................................................................................................................................................33

8. WARRANTY TERMS .......................................................................................................................... 34