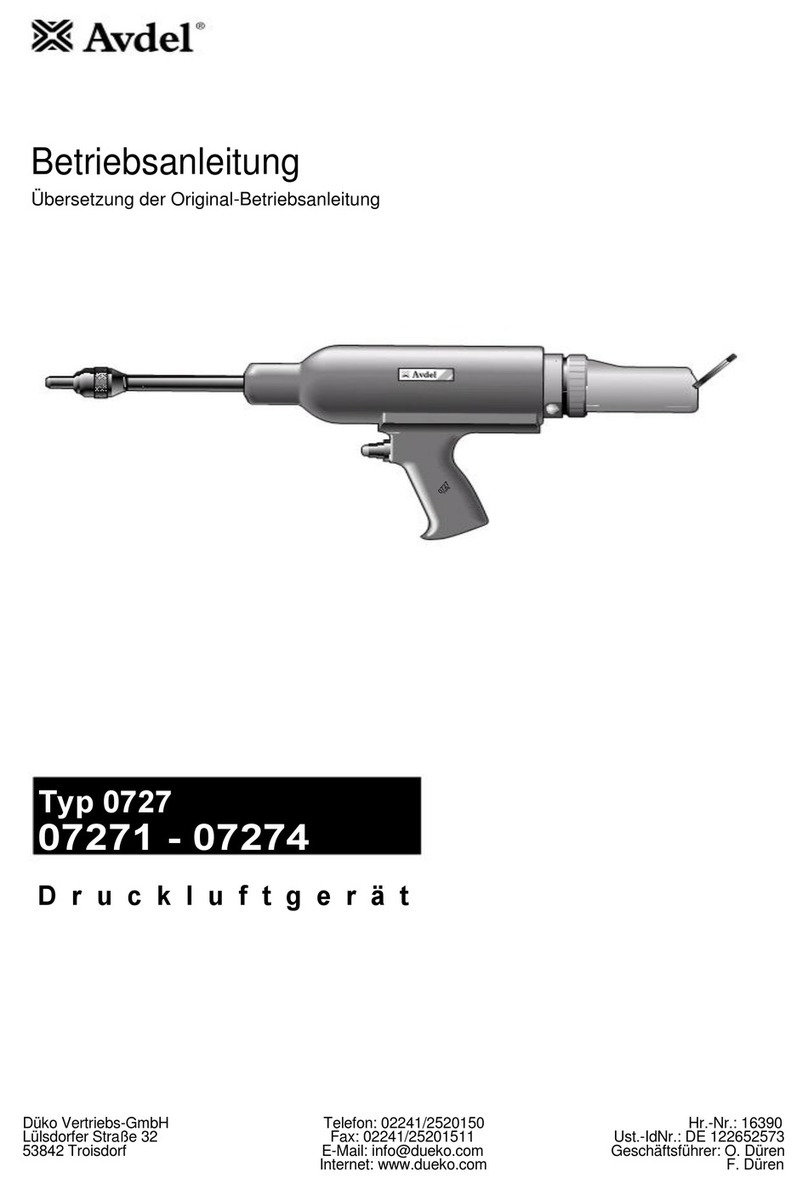

Avdel 07281 User manual

PA Avdel

An Acumenr Global Technologies Company

Instruction Manual

Pass onto user to

read and keep for reference

Jo-Bolt

&

Jo-Lok Power Tool

07281

07281

Jo-Bolt & Jo-Lok Power Tool

Pass onto user to read and keep for reference

07281

I n s t r u c t i o n M a n u a l

AVDEL

policy is one of continuous development. Specifications shown in this document may be subject to changes which

may be introduced after publication. For the latest information always consult Avdel.

SPECIFICATIONS FOR 07281 TOOL

AIR PRESSURE

Minimum - Maximum

-

5 - 8 bar

70 -

120 lbf/in

2

FREE AIR VOLUME REQUIRED

■

@

5.6 bar / 80 lbf/in

2

■

566 litres/ min

20

ft

3

/min

MOTOR SPEED

■

@ 70

lb/in

2

minimum

■

500 RPM

(clockwise)

CYCLE TIME

■

Approximately

■

5 seconds

NOISE LEVEL

■ ■

75 dB(A)

WEIGHT

■

Without nose equipment

■

1.5 kg

3.3 lb

VIBRATION

■

Less

than

■

2.5 m/ s

2

8 ft/s2

AVDEL policy is one of continuous development. Specifications shown in this document may be subject to changes which

may be introduced after publication. For the latest information always consult Avdel.

AIR PRESSURE Minimum - Maximum 5 - 8 bar 70 - 120 lbf/in2

FREE AIR VOLUME REQUIRED @ 5.6 bar / 80 lbf/in2566 litres/min 20 ft3 /min

MOTOR SPEED @ 70 lb/in2 minimum 500 RPM (clockwise)

CYCLE TIME Approximately 5 seconds

NOISE LEVEL 75 dB(A)

WEIGHT Without nose equipment 1.5 kg 3.3 lb

VIBRATION Less than 2.5 m/s28 ft/s2

S P E C I F I C A T I O N S F O R 0 7 2 8 1 T O O L

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

CONTENTS

SAFETY

Gene

ral

2

Specific to 07281 Tool

3

INTENT

OF USE

PUTTING IN TO SERVICE

NOSE

ASSEMBLIES

SERVICING

FAULT

DIAGNOSIS

General

4

I

Tool Dimensions / Selection

4 - 5

Air Supply

6

Operating Procedure

6

Accessories

7

Fitting/Servicing/Components

8-9

Fault Diagnosis Table

16

7

Regular Servicing

10

Maintenance

11 -13

General Assembly & Parts List

14-15

1

Fault Diagnosis Table 16

Fitting/Servicing/Components 8-9

Regular Servicing 10

Maintenance 11-13

General Assembly & Parts List 14-15

C

O N T E N T S

1

S A F E T Y

General 2

Specific to 07281 Tool 3

F AU L T D I A G N O S I S

N O S E A S S E M B L I E S

S E R V I C I N G

P U T T I N G I N T O S E R V I C E

General 4

I N T E N T O F U S E

Tool Dimensions / Selection 4 - 5

Air Supply 6

Operating Procedure 6

Accessories 7

AFETY

This instruction manual must be read with particular attention to the following safety rules,

by any person installing, operating, or servicing this tool.

DO NOT USE OUTSIDE THE DESIGN INTENT.

OD DO NOT USE EQUIPMENT WITH THIS TOOL/MACHINE OTHER THAN THAT

RECOMMENDED AND SUPPLIED BY AVDEL.

OD ANY MODIFICATION UNDERTAKEN BY THE CUSTOMER TO THE TOOL/MACHINE,

NOSE ASSEMBLIES, ACCESSORIES OR ANY EQUIPMENT SUPPLIED BY AVDEL OR THEIR

REPRESENTATIVES, SHALL BE THE CUSTOMER'S ENTIRE RESPONSIBILITY. AVDEL WILL BE

PLEASED TO ADVISE UPON ANY PROPOSED MODIFICATION.

OD THE TOOL/MACHINE MUST BE MAINTAINED IN A SAFE WORKING CONDITION AT

ALL TIMES AND EXAMINED AT REGULAR INTERVALS FOR DAMAGE AND FUNCTION BY

TRAINED COMPETENT PERSONNEL. ANY DISMANTLING PROCEDURE SHALL BE

UNDERTAKEN ONLY BY PERSONNEL TRAINED IN AVDEL PROCEDURES. DO NOT DISMANTLE

THIS TOOL/MACHINE WITHOUT PRIOR REFERENCE TO THE MAINTENANCE INSTRUCTIONS.

CONTACT AVDEL WITH YOUR TRAINING REQUIREMENTS.

IT THE TOOL/MACHINE SHALL AT ALL TIMES BE OPERATED IN ACCORDANCE WITH

RELEVANT HEALTH AND SAFETY LEGISLATION. IN THE U.K. THE "HEALTH AND SAFETY AT

WORK ETC. ACT 1974" APPLIES. ANY QUESTION REGARDING THE CORRECT OPERATION

OF THE TOOL/MACHINE AND OPERATOR SAFETY SHOULD BE DIRECTED TO AVDEL.

IT THE PRECAUTIONS TO BE OBSERVED WHEN USING THIS TOOL/MACHINE MUST BE

EXPLAINED BY THE CUSTOMER TO ALL OPERATORS.

IT ALWAYS DISCONNECT THE AIRLINE FROM THE TOOL/MACHINE INLET BEFORE

ATTEMPTING TO ADJUST, FIT OR REMOVE A NOSE ASSEMBLY.

Ts DO NOT OPERATE A TOOL/MACHINE THAT IS DIRECTED TOWARDS ANY PERSON(S).

ENSURE THAT VENT HOLES DO NOT BECOME BLOCKED OR COVERED AND THAT

HOSES ARE ALWAYS IN GOOD CONDITION.

2

S

A F E T Y

2

This instruction manual must be read with particular attention to the following safety rules,

by any person installing, operating, or servicing this tool.

DO NOT USE OUTSIDE THE DESIGN INTENT.

DO NOT USE EQUIPMENT WITH THIS TOOL/MACHINE OTHER THAN THAT

RECOMMENDED AND SUPPLIED BY AVDEL.

ANY MODIFICATION UNDERTAKEN BY THE CUSTOMER TO THE TOOL/MACHINE,

NOSE ASSEMBLIES, ACCESSORIES OR ANY EQUIPMENT SUPPLIED BY AVDEL OR THEIR

REPRESENTATIVES, SHALL BE THE CUSTOMER'S ENTIRE RESPONSIBILITY. AVDEL WILL BE

PLEASED TO ADVISE UPON ANY PROPOSED MODIFICATION.

THE TOOL/MACHINE MUST BE MAINTAINED IN A SAFE WORKING CONDITION AT

ALL TIMES AND EXAMINED AT REGULAR INTERVALS FOR DAMAGE AND FUNCTION BY

TRAINED COMPETENT PERSONNEL. ANY DISMANTLING PROCEDURE SHALL BE

UNDERTAKEN ONLY BY PERSONNEL TRAINED IN AVDEL PROCEDURES. DO NOT DISMANTLE

THIS TOOL/MACHINE WITHOUT PRIOR REFERENCE TO THE MAINTENANCE INSTRUCTIONS.

CONTACT AVDEL WITH YOUR TRAINING REQUIREMENTS.

THE TOOL/MACHINE SHALL AT ALL TIMES BE OPERATED IN ACCORDANCE WITH

RELEVANT HEALTH AND SAFETY LEGISLATION. IN THE U.K. THE “HEALTH AND SAFETY AT

WORK ETC. ACT 1974” APPLIES. ANY QUESTION REGARDING THE CORRECT OPERATION

OF THE TOOL/MACHINE AND OPERATOR SAFETY SHOULD BE DIRECTED TO AVDEL.

THE PRECAUTIONS TO BE OBSERVED WHEN USING THIS TOOL/MACHINE MUST BE

EXPLAINED BY THE CUSTOMER TO ALL OPERATORS.

ALWAYS DISCONNECT THE AIRLINE FROM THE TOOL/MACHINE INLET BEFORE

ATTEMPTING TO ADJUST, FIT OR REMOVE A NOSE ASSEMBLY.

DO NOT OPERATE A TOOL/MACHINE THAT IS DIRECTED TOWARDS ANY PERSON(S).

ENSURE THAT VENT HOLES DO NOT BECOME BLOCKED OR COVERED AND THAT

HOSES ARE ALWAYS IN GOOD CONDITION.

In

addition to the general safety rules opposite, the following specific safety points must also

be observed:

THE OPERATING PRESSURE SHALL NOT EXCEED 8 BAR - 120 LBF/IN

2

.

ID DO NOT OPERATE THE TOOL WITHOUT FULL NOSE EQUIPMENT IN PLACE.

WHEN USING THE TOOL, THE WEARING OF SAFETY GLASSES IS REQUIRED BOTH BY

THE OPERATOR AND OTHERS IN THE VICINITY TO PROTECT AGAINST FASTENER

PROJECTION, SHOULD A FASTENER BE PLACED 'IN AIR'. WE RECOMMEND WEARING

GLOVES IF THERE ARE SHARP EDGES OR CORNERS ON THE APPLICATION.

TAKE CARE TO AVOID ENTANGLEMENT OF LOOSE CLOTHES, TIES, LONG HAIR,

CLEANING RAGS ETC. IN THE MOVING PARTS OF THE TOOL WHICH SHOULD BE KEPT DRY

AND CLEAN FOR BEST POSSIBLE GRIP.

ID WHEN CARRYING THE TOOL FROM PLACE TO PLACE KEEP HANDS AWAY FROM THE

TRIGGER/LEVER TO AVOID INADVERTENT START UP.

ID ALWAYS ADOPT A FIRM FOOTING OR A STABLE POSITION BEFORE OPERATING THE

TOOL AND BE AWARE OF A TORQUE REACTION ON THE HANDS WHEN THE TOOL IS

OPERATING. GRIP THE TOOL FIRMLY TO BE ABLE TO COUNTER THE TORQUE REACTION,

BUT NOT TOO TIGHTLY.

ID KEEP HANDS AWAY FROM THE NOSE END OF THE TOOL.

THE TOOL IS NOT ELECTRICALLY INSULATED.

(!) THIS TOOL IS NOT DESIGNED FOR USE IN COMBUSTIBLE OR EXPLOSIVE

ATMOSPHERES.

3

3

In addition to the general safety rules opposite, the following specific safety points must also

be observed:

THE OPERATING PRESSURE SHALL NOT EXCEED 8 BAR - 120 LBF/IN2.

DO NOT OPERATE THE TOOL WITHOUT FULL NOSE EQUIPMENT IN PLACE.

WHEN USING THE TOOL, THE WEARING OF SAFETY GLASSES IS REQUIRED BOTH BY

THE OPERATOR AND OTHERS IN THE VICINITY TO PROTECT AGAINST FASTENER

PROJECTION, SHOULD A FASTENER BE PLACED ‘IN AIR’. WE RECOMMEND WEARING

GLOVES IF THERE ARE SHARP EDGES OR CORNERS ON THE APPLICATION.

TAKE CARE TO AVOID ENTANGLEMENT OF LOOSE CLOTHES, TIES, LONG HAIR,

CLEANING RAGS ETC. IN THE MOVING PARTS OF THE TOOL WHICH SHOULD BE KEPT DRY

AND CLEAN FOR BEST POSSIBLE GRIP.

WHEN CARRYING THE TOOL FROM PLACE TO PLACE KEEP HANDS AWAY FROM THE

TRIGGER/LEVER TO AVOID INADVERTENT START UP.

ALWAYS ADOPT A FIRM FOOTING OR A STABLE POSITION BEFORE OPERATING THE

TOOL AND BE AWARE OF A TORQUE REACTION ON THE HANDS WHEN THE TOOL IS

OPERATING. GRIP THE TOOL FIRMLY TO BE ABLE TO COUNTER THE TORQUE REACTION,

BUT NOT TOO TIGHTLY.

KEEP HANDS AWAY FROM THE NOSE END OF THE TOOL.

THE TOOL IS NOT ELECTRICALLY INSULATED.

THIS TOOL IS NOT DESIGNED FOR USE IN COMBUSTIBLE OR EXPLOSIVE

ATMOSPHERES.

223

8.75

C

<

)

< B >

46

>

1.81

27

1.06

t

40

1.57

I, Avdel

1

2

A

t

45

1.77

'L

146

5.75

133

5.25

Dimensions shown in bold are millimetres.

Other dimensions are in inches.

N TEN T OF USE

The pneumatic 07281 type tool is designed to place Avdel Jo-Bolt and Jo-Lock fasteners at high speed making it ideal for batch or flow-

line assembly in a wide variety of applications throughout all industries.

Use the selection table opposite to select a complete tool which will be fitted with the correct nose assembly for the fastener selected.

'A', 'B' and 'C' dimensions will help you assess the accessibility of your application.

It is also possible to order the base tool only (part number 07281-00300). For details of Nose Assemblies see pages 8 and 9.

4

The pneumatic 07281 type tool is designed to place Avdel Jo-Bolt and Jo-Lock fasteners at high speed making it ideal for batch or flow-

line assembly in a wide variety of applications throughout all industries.

Use the selection table opposite to select a complete tool which will be fitted with the correct nose assembly for the fastener selected.

`A’, `B’ and `C’ dimensions will help you assess the accessibility of your application.

It is also possible to order the base tool only (part number 07281-00300). For details of Nose Assemblies see pages 8 and 9.

4

IN T E N T O F U S E

Dimensions shown in bold are millimetres.

Other dimensions are in inches.

146

5.75

45

1.77

223

C

B

A

8.75

46

1.81

27

1.06

40

1.57

133

5.25

07281

7281 TOOL SELECTION

FASTEN ER TYPE

BODY

NOSE

(see

drawing

opposite

for A,Ei&C)

COMPLETE

JO-BOLT & JO-11)K BOLT

0

A (mm)

B(mm)

C (mm)

A (in)

B (in)

C (in)

NOSEASSY PAWN °

TOOL PART N°

HEXAGON HEAD

.164

12.45

22.94

31.52

1.24

07280-07000

07281-00005

(Alloy Steel &

.190

12.45

22.35

30.94

1.22

07280-07100

07281-00006

Stainless Steel)

.200

12.45

22.35

30.94

1.22

07280-07100

07281-00006

.249

13.46

22.35

30.94

1.22

07280-07300

07281-00008

.260

13.46

22.35

30.94

1.22

07280-07300

07281-00008

.312

15.75

24.13

32.71

.62

.95

1.29

07280-07400 07281-00010

90° & 100° CSK HEAD

.164

12.70

21.79

30.38

0

0

0

0

0 N

..

i

n i

n i

n i

n i

n i

n

•

•

•

•

•

•

*so

Co

Co

Co

Co

Co

0

Cr,

Ui

Ui

Ui

Os

1.20

07280-07500

07281-00025

(Alloy Steel &

.190

12.70

21.54

30.12

1.19

07280-07600

07281-00026

Stainless Steel)

.200

12.70

21.54

30.12

1.19

07280-07600

07281-00026

.249

12.70

21.67

30.25

1.19

07280-07700

07281-00028

.260

12.70

21.67

30.25

1.19

07280-07700

07281-00028

.312

14.35

22.86

31.44

1.24

07280-07800 07281-00030

5

5

7281 TOOL SELECTION

NOSE(see drawing opposite for A,B&C)

BODY

Ø

COMPLETE

TOOL PART Nº

NOSE ASSY PART N º

C (mm)A (mm)

FASTENER TYPE

JO-BOLT & JO-LOK BOLT B (mm) A (in) B (in) C (in)

.164 12.45 22.94 31.52 .49 .90 1.24 07280-07000 07281-00005

.190 12.45 22.35 30.94 .49 .88 1.22 07280-07100 07281-00006

.200 12.45 22.35 30.94 .49 .88 1.22 07280-07100 07281-00006

.249 13.46 22.35 30.94 .53 .88 1.22 07280-07300 07281-00008

.260 13.46 22.35 30.94 .53 .88 1.22 07280-07300 07281-00008

.312 15.75 24.13 32.71 .62 .95 1.29 07280-07400 07281-00010

.164 12.70 21.79 30.38 .50 .86 1.20 07280-07500 07281-00025

.190 12.70 21.54 30.12 .50 .85 1.19 07280-07600 07281-00026

.200 12.70 21.54 30.12 .50 .85 1.19 07280-07600 07281-00026

.249 12.70 21.67 30.25 .50 .85 1.19 07280-07700 07281-00028

.260 12.70 21.67 30.25 .50 .85 1.19 07280-07700 07281-00028

.312 14.35 22.86 31.44 .57 .90 1.24 07280-07800 07281-00030

HEXAGON HEAD

(Alloy Steel &

Stainless Steel)

90°& 100°CSK. HEAD

(Alloy Steel &

Stainless Steel)

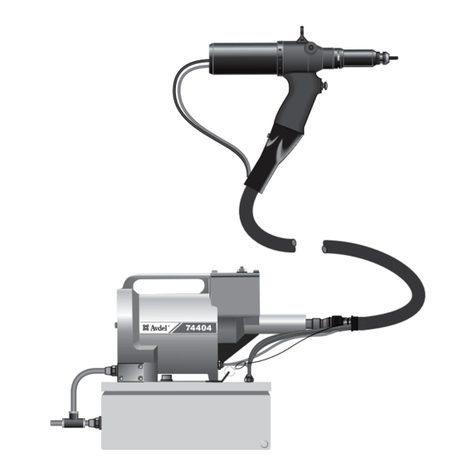

MAIN SUPPLY

DRAIN POINT

PRESSURE REGULATOR

AND FILTER

(DRAIN DAILY)

LUBRICATOR

STOP COCK

(USED DURING MAINTENANCE

OF FILTER/REGULATOR

OR LUBRICATION UNITS)

1

0

4

0

1

F

3

METRES

MAXIMUM

TAKE OFF POINT

FROM MAIN SUPPLY

UTTING INTO SERVICE

AIR SUPPLY

All tools are operated with compressed air at an optimum pressure of 5.5 bar. We recommend the use of pressure regulators and

automatic oiling/filtering systems on the main air supply. These should be fitted within 3 metres of the tool (see diagram below) to ensure

maximum tool life and minimum tool maintenance.

Air supply hoses should have a minimum working effective pressure rating of 150% of the maximum pressure produced in the system

or 10 bar, whichever is the highest. Air hoses should be oil resistant, have an abrasion resistant exterior and should be armoured where

operating conditions may result in hoses being damaged. All air hoses MUST have a minimum bore diameter of 6.4 millimetres or

1

/

4

inch.

Read servicing daily details page 10.

OPERATING PROCEDURE

OPTION 1

Ensure that the correct nose equipment is fitted.

•

Connect the tool to the air supply.

•

Place the fastener into the prepared hole of the application.

•

Locate the nose adaptor onto the head of the fastener, holding it

square to the application and applying slight pressure.

■

Operate the trigger. The tool will rotate the fastener bolt whilst

holding the nut stationary. At a predetermined load the bolt shears

leaving the fastener placed in the application.

OPTION 2

▪

Ensure that the correct nose equipment is fitted.

•

Connect the tool to the air supply.

•

Insert the fastener into the tool ensuring the fastener locates in the

nose adaptor.

With the fastener on the tool locate it into the prepared hole in the

application.

•

Operate the trigger. The tool will rotate the fastener bolt whilst

holding the nut stationary. At a predetermined load the bolt shears

leaving the fastener placed in the application.

6

6

P

U T T I N G I N T O S E R V I C E

A I R S U P P L Y

All tools are operated with compressed air at an optimum pressure of 5.5 bar. We recommend the use of pressure regulators and

automatic oiling/filtering systems on the main air supply. These should be fitted within 3 metres of the tool (see diagram below) to ensure

maximum tool life and minimum tool maintenance.

Air supply hoses should have a minimum working effective pressure rating of 150% of the maximum pressure produced in the system

or 10 bar, whichever is the highest. Air hoses should be oil resistant, have an abrasion resistant exterior and should be armoured where

operating conditions may result in hoses being damaged. All air hoses MUST have a minimum bore diameter of 6.4 millimetres or 1/4inch.

Read servicing daily details page 10.

OPTION 2

Ensure that the correct nose equipment is fitted.

Connect the tool to the air supply.

Insert the fastener into the tool ensuring the fastener locates in the

nose adaptor.

With the fastener on the tool locate it into the prepared hole in the

application.

Operate the trigger. The tool will rotate the fastener bolt whilst

holding the nut stationary. At a predetermined load the bolt shears

leaving the fastener placed in the application.

O P E R A T I N G P R O C E D U R E

■

■

■

■

■

07281

8

6

4

2

0

10

12

14

16

TAKE OFF POINT

FROM MAIN SUPPLY

STOP COCK

(USED DURING MAINTENANCE

OF FILTER/REGULATOR

OR LUBRICATION UNITS)

MAIN SUPPLY

DRAIN POINT

PRESSURE REGULATOR

AND FILTER

(DRAIN DAILY)

LUBRICATOR

3

M

E

T

R

E

S

M

A

X

I

M

U

M

OPTION 1

Ensure that the correct nose equipment is fitted.

Connect the tool to the air supply.

Place the fastener into the prepared hole of the application.

Locate the nose adaptor onto the head of the fastener, holding it

square to the application and applying slight pressure.

Operate the trigger. The tool will rotate the fastener bolt whilst

holding the nut stationary. At a predetermined load the bolt shears

leaving the fastener placed in the application.

■

■

■

■

■

ACCESSO RI ES

Two different accessories are available to make the connection to your air supply:

Hose Connector

Hose Assembly

part n° 07005-00276

part n° 07008-000324

7

7

A C C E S S O R I E S

Two different accessories are available to make the connection to your air supply:

L = 137 cm

1/4” BSP

TO FIT 6.4 mm (1/4”) BORE PIPE

Hose Assembly

part nº 07008-000324

Hose Connector

part nº 07005-00276

\AAA*

t\i\i\i\i\i\i\i\i\i\i\i\i\i\i\i\i\i\i\

N

OSE ASSEM BLI ES

Nose assemblies are designed to place a specific size and type of head for either Jo-Bolt or Jo-Lok fasteners. If you have purchased

a complete tool, it will already be fitted with the correct nose assembly for your fastener.

It is essential that the correct nose assembly is fitted prior to operating the tool.

By

knowing your original complete tool part number

or the details of the fastener to be placed, you can select a new complete nose assembly using the selection table on page 5.

FITTING INSTRUCTIONS

IMPORTANT

The air supply must be disconnected when fifting or removing nose assemblies unless specifically instructed otherwise.

If still fitted, remove the housing from the base tool.

•

Insert spring

4

into front of the tool over pin of driving socket assembly the insert stop pin

3

into spring

4.

•

Locate wrench adaptor

2

so that the forked end locates in slots in driving socket assembly of base tool.

-

Screw housing onto front of tool and tighten with a spanner (left hand thread).

Screw nose adaptor 1 into housing and tighten with a spanner (left hand thread).

For applications with restricted access the nose assembly can be extended by 4 inches with the addition of a long wrench adaptor (item

6 below and opposite) and extension tube (item 5 below and opposite). This is only available when placing fasteners of diameters listed

in the table opposite.

To

fit extension unit to base tool.

•

Remove the housing from the base tool.

•

Insert spring

4

into front of the tool over pin of driving socket assembly, then insert stop pin

3 into spring 4.

•

Locate long wrench adaptor

2

into tool, ensuring forked end locates in slots of driving socket assembly of base tool.

Screw housing onto front of tool and tighten with a spanner (left hand thread).

Screw extension tube

2

into front of housing and tighten with a spanner.

Screw nose adaptor 1 into front of extension tube and tighten with a spanner (left hand thread).

1

5

I o

HOUSING

\i\i\i\i\i\i

4

8

8

NO S E A S S E M B L I E S

Nose assemblies are designed to place a specific size and type of head for either Jo-Bolt or Jo-Lok fasteners. If you have purchased

a complete tool, it will already be fitted with the correct nose assembly for your fastener.

It is essential that the correct nose assembly is fitted prior to operating the tool. By knowing your original complete tool part number

or the details of the fastener to be placed, you can select a new complete nose assembly using the selection table on page 5.

FITTING INSTRUCTIONS

I M P O R T A N T

The air supply must be disconnected when fitting or removing nose assemblies unless specifically instructed otherwise.

If still fitted, remove the housing from the base tool.

Insert spring 4into front of the tool over pin of driving socket assembly the insert stop pin 3into spring 4.

Locate wrench adaptor 2so that the forked end locates in slots in driving socket assembly of base tool.

Screw housing onto front of tool and tighten with a spanner (left hand thread).

Screw nose adaptor 1into housing and tighten with a spanner (left hand thread).

For applications with restricted access the nose assembly can be extended by 4 inches with the addition of a long wrench adaptor (item

6 below and opposite) and extension tube (item 5 below and opposite). This is only available when placing fasteners of diameters listed

in the table opposite.

To fit extension unit to base tool.

Remove the housing from the base tool.

Insert spring 4into front of the tool over pin of driving socket assembly, then insert stop pin 3into spring 4.

Locate long wrench adaptor 2into tool, ensuring forked end locates in slots of driving socket assembly of base tool.

Screw housing onto front of tool and tighten with a spanner (left hand thread).

Screw extension tube 2 into front of housing and tighten with a spanner.

Screw nose adaptor 1 into front of extension tube and tighten with a spanner (left hand thread).

■

■

■

■

■

■

■

■

■

■

■

34

HOUSING 2

1

634

15

HOUSING

SERVICING INSTRUCTION S

Nose assemblies should be serviced at weekly intervals.

Remove the complete nose assembly using the reverse procedure to the 'Fitting Instructions'.

■

Any worn or damaged part should be replaced.

■

Particularly check wear on nose adaptor.

■

Check springs are not distorted.

■

Lubricate wrench adaptor with high pressure grease (eg Shell Alvania E.P.I.)

■

Assemble according to fitting instructions.

NOSE ASSEMBLY COMPONENTS

The table below lists all nose assemblies available. Each nose assembly represents a unique assembly of components which can be

ordered individually. Components numbers refer to the text and illustration opposite. We recommend some stock as items will need

regular replacement. Read the nose assemblies servicing instructions above carefully.

NOSEASSY

1

2

3

4

07280-07000

07280-04005

07280-02105

07280-02001

07280-02002

07280-07100

07280-04006

07280-02106

07280-02001

07280-02002

07280-07300

07280-04008

07280-02108

07280-02001

07280-02002

07280-07400

07280-04010

07280-02110

07280-02001

07280-02002

07280-07500

07280-03005

07280-02105

07280-02001

07280-02002

07280-07600

07280-03006

07280-02106

07280-02001

07280-02002

07280-07700

07280-03008

07280-02108

07280-02001

07280-02002

07280-07800

07280-03010

07280-02110

07280-02001

07280-02002

Refer to the table below to order the correct long wrench adaptor and extension tube.

FASIEN ER BODY 0

5

6

.190

.200

.249

.260

07280-06106

07280-06106

07280-06108

07280-06108

07280-06001

07280-06001

07280-06001

07280-06001

9

9

Refer to the table below to order the correct long wrench adaptor and extension tube.

SERVICING INSTRUCTIONS

Nose assemblies should be serviced at weekly intervals.

Remove the complete nose assembly using the reverse procedure to the ‘Fitting Instructions’.

Any worn or damaged part should be replaced.

Particularly check wear on nose adaptor.

Check springs are not distorted.

Lubricate wrench adaptor with high pressure grease (eg Shell Alvania E.P.I.)

Assemble according to fitting instructions.

■

■

■

■

■

■

NOSE ASSEMBLY COMPONENTS

The table below lists all nose assemblies available. Each nose assembly represents a unique assembly of components which can be

ordered individually. Components numbers refer to the text and illustration opposite. We recommend some stock as items will need

regular replacement. Read the nose assemblies servicing instructions above carefully.

1

NOSE ASSY 243

07280-07000 07280-04005 07280-02105 07280-02001 07280-02002

07280-07100 07280-04006 07280-02106 07280-02001 07280-02002

07280-07300 07280-04008 07280-02108 07280-02001 07280-02002

07280-07400 07280-04010 07280-02110 07280-02001 07280-02002

07280-07500 07280-03005 07280-02105 07280-02001 07280-02002

07280-07600 07280-03006 07280-02106 07280-02001 07280-02002

07280-07700 07280-03008 07280-02108 07280-02001 07280-02002

07280-07800 07280-03010 07280-02110 07280-02001 07280-02002

5

FASTENER BODY Ø 6

.190 07280-06106 07280-06001

.200 07280-06106 07280-06001

.249 07280-06108 07280-06001

.260 07280-06108 07280-06001

ERVICING THE TOOL

Regular servicing should be carried out and a comprehensive inspection performed annually or every 200000 cycles, whichever is

soonest.

IMPORTANT

The employer is responsible for ensuring that tool maintenance instructions are given to the appropriate personnel. The

operator should not be involved in maintenance or repair of the tool unless properly trained.

DAILY

Daily, before use or when first putting the tool into service, pour a fewdrops of clean, light lubricating oil into the air inlet of the tool if no lubricator

is fitted on air supply. If the tool is in continuous use, the air hose should be disconnected from the main air supply and the tool lubricated every

two to three hours.

Check for air leaks. If damaged, hoses and couplings should be replaced by new items.

If there is no filter on the pressure regulator, bleed the air line to clear it of accumulated dirt or water before connecting the air hose to the tool.

If a filter is fitted, drain it.

Check that the nose assembly is correct.

WEEKLY

Fully dismantle and service the nose assembly (see instructions page 9).

Check for air leaks in the air supply hose and fittings.

For lubricating internal tool parts other than those described previously, use Moly Lithium Grease EP3753 (part number 07992-00020)

MO LY LITHIUM GREASE EP 3753

SAFETY

DATA

FIRST AID

FIRE

SKIN: As the grease is completely water resistant it is best

FLASH POINT: Above 220°C.

removed with an approved emulsifying skin cleaner.

Not classified as flammable.

Suitable extinguishing media: CO,, Halon or water spray

INGESTION: Make the individual drink 30m1 Milk of

if applied by an experienced operator.

Magnesia, preferably in a cup of milk.

EYES: Irritant but not harmful. Irrigate with water and

HANDLING

seek medical attention.

Use barrier cream or oil resistant gloves

ENVIRONMENT

STORAGE

Scrape up for burning or disposal on approved site.

Away from heat and oxidising agent.

10

10

S

E R V I C I N G T H E T O O L

■

■

■

■

Regular servicing should be carried out and a comprehensive inspection performed annually or every 200000 cycles, whichever is

soonest.

I M P O R T A N T

The employer is responsible for ensuring that tool maintenance instructions are given to the appropriate personnel. The

operator should not be involved in maintenance or repair of the tool unless properly trained.

D A I L Y

Daily, before use or when first putting the tool into service, pour a few drops of clean, light lubricating oil into the air inlet of the tool if no lubricator

is fitted on air supply. If the tool is in continuous use, the air hose should be disconnected from the main air supply and the tool lubricated every

two to three hours.

Check for air leaks. If damaged, hoses and couplings should be replaced by new items.

If there is no filter on the pressure regulator, bleed the air line to clear it of accumulated dirt or water before connecting the air hose to the tool.

If a filter is fitted, drain it.

Check that the nose assembly is correct.

W E E K L Y

Fully dismantle and service the nose assembly (see instructions page 9).

Check for air leaks in the air supply hose and fittings.

M O L Y L I T H I U M G R E A S E E P 3 7 5 3S A F E T Y D A T A

For lubricating internal tool parts other than those described previously, use Moly Lithium Grease EP3753 (part number 07992-00020)

FIRST AID

SKIN: As the grease is completely water resistant it is best

removed with an approved emulsifying skin cleaner.

INGESTION: Make the individual drink 30ml Milk of

Magnesia, preferably in a cup of milk.

EYES: Irritant but not harmful. Irrigate with water and

seek medical attention.

ENVIRONMENT

Scrape up for burning or disposal on approved site.

FIRE

FLASH POINT: Above 220°C.

Not classified as flammable.

Suitable extinguishing media: CO2, Halon or water spray

if applied by an experienced operator.

HANDLING

Use barrier cream or oil resistant gloves

STORAGE

Away from heat and oxidising agent.

■

■

MAINTENANCE

Every 200000 cycles the tool should be completely dismantled and components replaced where worn, damaged or when recommended.

All '0' rings and seals should be replaced with new ones and lubricated with Moly Lithium grease EP 3753 before assembling.

IMPORTANT

Safety Instructions appear on pages 2 & 3.

The employer is responsible for ensuring that tool maintenance instructions are given to the appropriate personnel.

The operator should not be involved in maintenance or repair of the tool unless properly trained.

The airline must be disconnected before any servicing or dismantling is attempted, unless specifically instructed not to.

It is recommended that any dismantling operation be carried out in clean conditions.

Item numbers in

bold

refer to the General Assembly drawing and parts list (pages 14 and 15).

Prior to dismantling the tool it is nesessary to remove the nose assembly. For simple removal instructions see the nose assemblies section,

pages 8 and 9.

For total tool servicing we advise that you proceed with the dismantling of sub-assemblies in the order shown on page 12.

11

11

M A I N T E N A N C E

Every 200000 cycles the tool should be completely dismantled and components replaced where worn, damaged or when recommended.

All ‘O’ rings and seals should be replaced with new ones and lubricated with Moly Lithium grease EP 3753 before assembling.

I M P O R T A N T

Safety Instructions appear on pages 2 & 3.

The employer is responsible for ensuring that tool maintenance instructions are given to the appropriate personnel.

The operator should not be involved in maintenance or repair of the tool unless properly trained.

The airline must be disconnected before any servicing or dismantling is attempted, unless specifically instructed not to.

It is recommended that any dismantling operation be carried out in clean conditions.

Item numbers in bold refer to the General Assembly drawing and parts list (pages 14 and 15).

Prior to dismantling the tool it is nesessary to remove the nose assembly. For simple removal instructions see the nose assemblies section,

pages 8 and 9.

For total tool servicing we advise that you proceed with the dismantling of sub-assemblies in the order shown on page 12.

HAN DIE ASSEMBLY

—

Grip the tool pistol grip handle in a vice fitted with soft jaws.

■

Unscrew nose assembly from housing

1.

■

Using a spanner on the flats of ring gear 10, remove front gear assembly

3

and by the use of the flats of housing 1, unscrew rear gear assembly

13.

■

Prise '0' ring

23

from handle assembly

36

and remove spacer

54.

•

Remove tool from vice and gently tap the front end of body assembly

36

on a wooden block. The motor assembly

24

will slide out. Return tool

to the vice.

■

Unscrew silencer retainer assembly 45and remove perforated washer

46,

silencer bodies

41

and silencer element

47.

•

Unscrew nipple

44

from adaptor

43,

and adaptor

43

from body assembly

36.

Remove filter

42.

■

Tap out roll pin

27

and carefully pull out the trigger assembly.

■

Drive out pin

52

from trigger

53

and pull off trigger

53

from valve

38.

•

Remove '0' rings

49

and

39

from valve

38

and '0' rings

50

and

40

from valve body

48.

IMPORTANT

Do NOT remove knob 37 from body assembly 36

FRONT GEAR ASSEM BLY (previously removed).

■■■■■■■

Unscrew driving socket assembly

34

from Adaptor

2.

Unscrew adaptor

2

from planet gear spindle

12.

Tap out internal assembly from ring gear 10.

Remove wave washer 11.

Remove bearings

4

and

7

and spacer

9

from planet gear spindle

12.

Tap out two planet gear shafts

6

and remove two planet gears

5

and bearings

8

from planet gear

5.

Press out bearing

8

from planet gears

5.

■

Assemble in reverse order of dismantling.

REAR GEAR ASSEMBLY

Pull off spacer

19.

Hold housing

15

and push out internal assembly from the front end.

Remove two bearings

21

and spacers

19

from planet gear spindle

14.

Push out two shafts

17

and slide out two planet gears

18

together with two bearings

20.

Press bearings out of planet gears

18.

Remove circlip

22

from housing

15.

Assemble in reverse order to dismantling.

12

12

HANDLE ASSEMBLY

Grip the tool pistol grip handle in a vice fitted with soft jaws.

Unscrew nose assembly from housing 1.

Using a spanner on the flats of ring gear 10, remove front gear assembly 3and by the use of the flats of housing 1, unscrew rear gear assembly 13.

Prise ‘O’ ring 23 from handle assembly 36 and remove spacer 54.

Remove tool from vice and gently tap the front end of body assembly 36 on a wooden block. The motor assembly 24 will slide out. Return tool

to the vice.

Unscrew silencer retainer assembly 45and remove perforated washer 46, silencer bodies 41 and silencer element 47.

Unscrew nipple 44 from adaptor 43, and adaptor 43 from body assembly 36. Remove filter 42.

Tap out roll pin 27 and carefully pull out the trigger assembly.

Drive out pin 52 from trigger 53 and pull off trigger 53 from valve 38.

Remove ‘O’ rings 49 and 39 from valve 38 and ‘O’ rings 50 and 40 from valve body 48.

IMPORTANT

Do NOT remove knob 37 from body assembly 36

FRONT GEAR ASSEMBLY (previously removed).

Unscrew driving socket assembly 34 from Adaptor 2.

Unscrew adaptor 2from planet gear spindle 12.

Tap out internal assembly from ring gear 10.

Remove wave washer 11.

Remove bearings 4 and 7and spacer 9from planet gear spindle 12.

Tap out two planet gear shafts 6and remove two planet gears 5and bearings 8from planet gear 5.

Press out bearing 8from planet gears 5.

Assemble in reverse order of dismantling.

REAR GEAR ASSEMBLY

Pull off spacer 19.

Hold housing 15 and push out internal assembly from the front end.

Remove two bearings 21 and spacers 19 from planet gear spindle 14.

Push out two shafts 17 and slide out two planet gears 18 together with two bearings 20.

Press bearings out of planet gears 18.

Remove circlip 22 from housing 15.

Assemble in reverse order to dismantling.

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

M 010 R ASSEM BLY

Remove locating pin

35

from side of front end plate

25.

Hold front end plate

25

and tap splined end of rotor

28

with a soft hammer so as not to damage the splines and remove front end plate

25

and

bearing

26.

Remove

cylinder

29

complete with roll pin

27

and pin

31.

Remove

the five rotor blades

30

from rotor

28.

Support rear end plate

32

using a piece of tube with a bore diameter as close as possible to largest diameter of rotor

28,

then tap non-splined

end of rotor

28

to remove it from rear end plate

32

and bearing

33.

Using a suitable punch, tap out bearing

26

from front end plate

25

and bearing

33

from rear end plate

32.

When assembling, make sure that locating pin

35

in front end plate

25

locates in groove in the front bore of handle assembly

36.

Pay special attention to front end plate

25

and rear end plate

32,

ensuring they are free from burrs and surface marking. If necessary, lap faces

that abut cylinder

29

on a flat fine grade abrasive paper.

Press fit bearings

26 & 33

into front and rear end plates

25 & 32.

Support bearing

33

in rear end plate

32

on its inner ring and using a soft hammer, tap rotor

28

on its splined end until rotor

28

locates against

rear end plate

32.

Support inner face of rear end plate

32

as close as possible to largest diameter of rotor

28.

Tap non-splined end of rotor

28

until a clearance of 0.040 mm (0.0015 in) to 0.065 mm (0.0025 in) is obtained between inner face of rear

end plate

32

and rotor

28.

Check clearance by pulling rotor

28

away from rear end plate

32

and bearing

33.

■

Spin rotor

28

ensuring that it rotates freely in rear end plate bearing

32.

■

Locate cylinder

29

with pin

31

to rear end plate

32

and check ports in rear end plate

32

align with ports in cylinder

29.

■

Insert five rotor blades

30

into rotor

28.

■

Fit front end plate

25

to cylinder

29

with locating pin

27.

■

Ensure rotor 28

spins freely.

■

Refit motor in reverse order to removal.

F

Complete assembly in reverse order of dismantling.

IMPORTANT

Checked the tool against daily and weekly servicing.

13

MOTOR ASSEMBLY

Remove locating pin 35 from side of front end plate 25.

Hold front end plate 25 and tap splined end of rotor 28 with a soft hammer so as not to damage the splines and remove front end plate 25 and

bearing 26.

Remove cylinder 29 complete with roll pin 27 and pin 31.

Remove the five rotor blades 30 from rotor 28.

Support rear end plate 32 using a piece of tube with a bore diameter as close as possible to largest diameter of rotor 28, then tap non-splined

end of rotor 28 to remove it from rear end plate 32 and bearing 33.

Using a suitable punch, tap out bearing 26 from front end plate 25 and bearing 33 from rear end plate 32.

When assembling, make sure that locating pin 35 in front end plate 25 locates in groove in the front bore of handle assembly 36.

Pay special attention to front end plate 25 and rear end plate 32, ensuring they are free from burrs and surface marking. If necessary, lap faces

that abut cylinder 29 on a flat fine grade abrasive paper.

Press fit bearings 26 & 33 into front and rear end plates 25 & 32.

Support bearing 33 in rear end plate 32 on its inner ring and using a soft hammer, tap rotor 28 on its splined end until rotor 28 locates against

rear end plate 32.

Support inner face of rear end plate 32 as close as possible to largest diameter of rotor 28.

Tap non-splined end of rotor 28 until a clearance of 0.040 mm (0.0015 in) to 0.065 mm (0.0025 in) is obtained between inner face of rear

end plate 32 and rotor 28.

Check clearance by pulling rotor 28 away from rear end plate 32 and bearing 33.

Spin rotor 28 ensuring that it rotates freely in rear end plate bearing 32.

Locate cylinder 29 with pin 31 to rear end plate 32 and check ports in rear end plate 32 align with ports in cylinder 29.

Insert five rotor blades 30 into rotor 28.

Fit front end plate 25 to cylinder 29 with locating pin 27.

Ensure rotor 28 spins freely.

Refit motor in reverse order to removal.

Complete assembly in reverse order of dismantling.

13

I M P O R T A N T

Checked the tool against daily and weekly servicing.

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

1

36

L_I

24

15 17 23 25 35

28

30 32

20 54

21

53

52 51 50 49

40 48

47

46

45

34 12 11

42

43

44

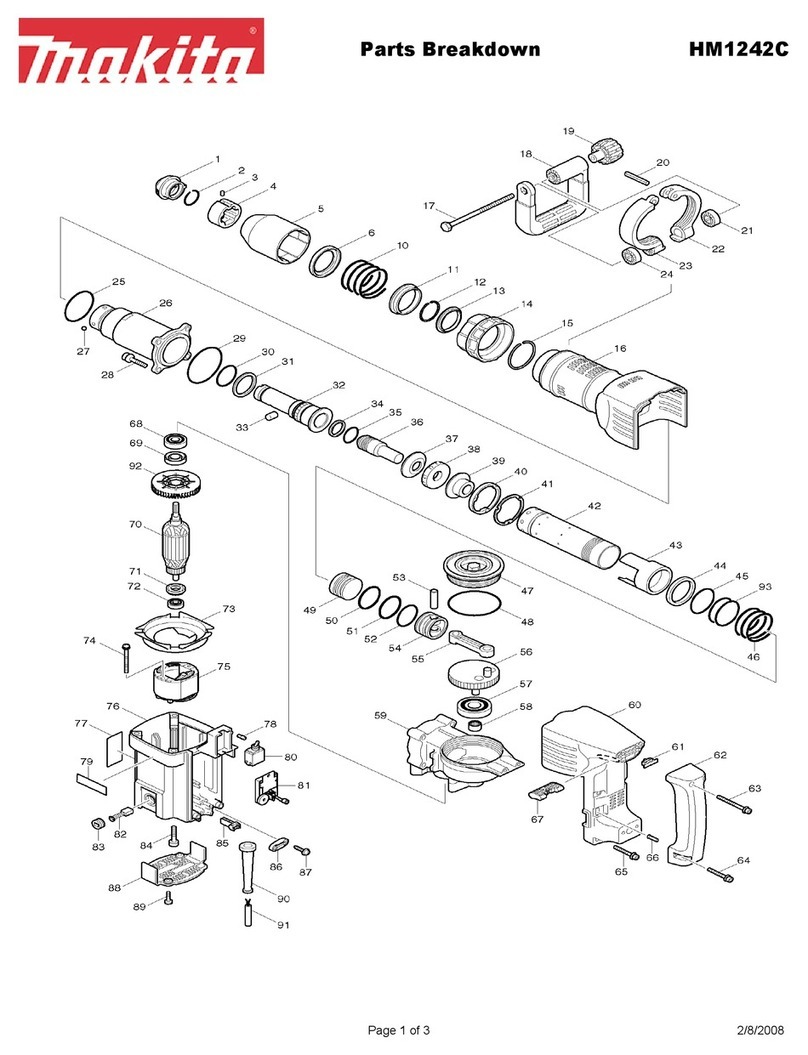

GEN ERAL ASSEMBLY OF BASE MOL 07281-00300

14

GENERAL ASSEMBLY OF BASE TOOL 07281-00300

40 48

5052 51 49

47

46

45

19 27 29

30

43

42

44

41

39

38

37

40

35 28

31 33 36

32

9101112 8 22 20 54

21 537

34

6

54

3

2114

13

16 18 26

15 23

17 25

24

07281-00300 PARTS LIST

MY!

PARrN°

DESCRIPTION

Q1Y

SPARES

MY!

PARrN°

DESCRIPTION

Q1Y

SPARES

01

08281-00411

HOUSING

1

-

29

08281-00404

•

CYLINDER

1

-

02

08281-00418

ADAPTOR

1

-

30

08430-00608

. ROTOR BLADE

5

5

03

08281-00401

FRONT GEAR ASSEMBLY (04-12)

1

-

31

08435-00203

•

PIN

1

1

04

08433-00239

.

BEARING

1

-

32

08281-00403

. REAR END PLATE

1

05

08430-00702

.

PLANET GEAR

2

-

33

08430-00606

. BEARING

1

-

06

08430-00704

.

SHAFT

2

-

34

07280-00400

DRIVING SOCKET ASSEMBLY

1

-

07

08430-00705

.

BEARING

1

-

35

08435-00202

LOCATING PIN

1

-

08

08430-00703

.

BEARING

2

-

36

08281-00419

HANDLE ASSEMBLY

1

-

09

08281-00413

•

SPACER

1

-

37

08281-00410

KNOB

1

-

10

08281-00417

•

RING GEAR

1

-

38

08281-00408

VALVE

1

-

11

08281-00414

•

WAVE WASHER

1

1

39

08520-00209

'0' RING

1

1

12

08281-00415

•

PLANET GEAR SPINDLE

1

-

40

08415-00207

'0' RING

2

1

13

08430-00700

REAR GEAR ASSEMBLY (14-22)

1

-

41

08415-00205

SILENCER BODY

2

2

14

08430-00709

•

PLANET GEAR SPINDLE

1

-

42

08415-00201

FILTER

1

1

15

08430-00708

.

HOUSING

1

-

43

08415-00202

ADAPTOR

1

16

08430-00701

•

SPACER

1

-

44

08433-00221

NIPPLE

1

-

17

08430-00704

•

SHAFT

2

-

45

08415-00203

SILENCER RETAINER ASSEMBLY

1

1

18

08430-00702

•

PLANET GEAR

2

-

46

08432-00201

WASHER

1

1

19

08430-00706

•

SPACER

1

-

47

08415-00204

SILENCER

1

1

20

08430-00703

.

BEARING

2

-

48

08281-00407

VALVE BODY

1

21

08430-00705

•

BEARING

2

-

49

08441-00402

'0' RING

1

1

22

08430-00707

•

CI RCLIP

1

1

50

08520-00215

'0' RING

1

1

23

08522-00205

'0' RING

1

1

51

08524-00207

ROLL PIN

1

1

24

08281-00402

MOTOR ASSEMBLY (25-33)

1

-

52

08433-00233

PIN

1

1

25

08281-00416

.

LOWER END PLATE

1

-

53

08281-00405

TRIGGER

1

26

08430-00601

•

BEARING

1

-

54

08430-00215

SPACER

1

-

27

08433-00233

.

ROLL PIN

1

1

55

08415-00234

NAMEPLATE

2

NOT SHOWN

28

08430-00605

•

ROTOR

1

-

15

01 08281-00411 HOUSING 1 -

02 08281-00418 ADAPTOR 1 -

03 08281-00401 FRONT GEAR ASSEMBLY (04-12) 1-

04 08433-00239

●

BEARING 1 -

05 08430-00702

●

PLANET GEAR 2 -

06 08430-00704

●

SHAFT 2 -

07 08430-00705

●

BEARING 1 -

08 08430-00703

●

BEARING 2 -

09 08281-00413

●

SPACER 1 -

10 08281-00417

●

RING GEAR 1 -

11 08281-00414

●

WAVE WASHER 11

12 08281-00415

●

PLANET GEAR SPINDLE 1-

13 08430-00700 REAR GEAR ASSEMBLY (14-22) 1-

14 08430-00709

●

PLANET GEAR SPINDLE 1-

15 08430-00708

●

HOUSING 1 -

16 08430-00701

●

SPACER 1 -

17 08430-00704

●

SHAFT 2 -

18 08430-00702

●

PLANET GEAR 2 -

19 08430-00706

●

SPACER 1 -

20 08430-00703

●

BEARING 2 -

21 08430-00705

●

BEARING 2 -

22 08430-00707

●

CIRCLIP 1 1

23 08522-00205 'O' RING 1 1

24 08281-00402 MOTOR ASSEMBLY (25-33) 1-

25 08281-00416

●

LOWER END PLATE 1-

26 08430-00601

●

BEARING 1 -

27 08433-00233

●

ROLL PIN 1 1

28 08430-00605

●

ROTOR 1 -

29 08281-00404

●

CYLINDER 1 -

30 08430-00608

●

ROTOR BLADE 55

31 08435-00203

●

PIN 1 1

32 08281-00403

●

REAR END PLATE 1-

33 08430-00606

●

BEARING 1 -

34 07280-00400 DRIVING SOCKET ASSEMBLY 1-

35 08435-00202 LOCATING PIN 1 -

36 08281-00419 HANDLE ASSEMBLY 1-

37 08281-00410 KNOB 1 -

38 08281-00408 VALVE 1 -

39 08520-00209 'O' RING 1 1

40 08415-00207 'O' RING 2 1

41 08415-00205 SILENCER BODY 2 2

42 08415-00201 FILTER 1 1

43 08415-00202 ADAPTOR 1 -

44 08433-00221 NIPPLE 1 -

45 08415-00203 SILENCER RETAINER ASSEMBLY 11

46 08432-00201 WASHER 1 1

47 08415-00204 SILENCER 1 1

48 08281-00407 VALVE BODY 1 -

49 08441-00402 'O' RING 1 1

50 08520-00215 'O' RING 1 1

51 08524-00207 ROLL PIN 1 1

52 08433-00233 PIN 1 1

53 08281-00405

TRIGGER

1-

54 08430-00215 SPACER 1 -

55 08415-00234 NAMEPLATE 2

NOT SHOWN

ITEM PART Nº DESCRIPTION QTY SPARESITEM PART Nº DESCRIPTION QTY SPARES

07281-00300 PARTS LIST

AULT DIAGNOSIS

FAULT DIAGNOSIS TABLE

SYMPTOM

POSSIBLE CAUSE

REMEDY

Tool runs slowly

—

0 Incorrect bore of hose

—

0 Insufficient air volume

—

0 Tool not properly lubricated internally

—

0 Tool not properly lubricated

—

0 Restricted air pressure/volume

—

0 Ensure bore of hose is 6.4 mm minimum

—

0 Ensure there is no restriction in the air supply or connections

—

0 Lubricate as per instructions

—

0 Depress button several times after lubricating tool

—

0 Ensure there is no restriction in the air supply

Tool fails to start

16

16

F A U L T D I A G N O S I S T A B L E

F

A U L T D I A G N O S I S

SYMPTOM POSSIBLE CAUSE REMEDY

Tool runs slowly ➝Incorrect bore of hose ➝Ensure bore of hose is 6.4 mm minimum

➝Insufficient air volume ➝Ensure there is no restriction in the air supply or connections

➝Tool not properly lubricated internally ➝Lubricate as per instructions

➝Tool not properly lubricated ➝Depress button several times after lubricating tool

Tool fails to start ➝Restricted air pressure/volume ➝Ensure there is no restriction in the air supply

Declaration of Conformity

We,

Avdel UK Limited, Mundells, Welwyn Garden City, Herts, AL7 1EZ

declare under our sole responsibility that the product

type 07281

Serial N°

to which this declaration relates is in conformity with the following standards or other formative documents

EN292 part 1 and part 2

ISO 8662 part 1 and part 7

ISO 3744 and PNEUROP test code PN8TC1

ISO PREN792 part 6

following the provisions of the Machine Directive 98/37/EC

This box contains a power tool which is in conformity with Machines Directive

98/37/EC. The 'Declaration of Conformity' is contained within.

Welwyn Garden City - date of issue

A. Seewraj

Product Engineering Manager - Automation Tools

Engineered Fastening and Assembly Systems

C

E

®

TM

Products mentioned and /or illustrated within this publication are subject to patent, design or copyright protection in many countries.

® © ™ Products mentioned and /or illustrated within this publication are subject to patent, design or copyright protection in many countries.

Engineered Fastening and Assembly Systems

Declaration of Conformity

We, Avdel UK Limited, Mundells, Welwyn Garden City, Herts, AL7 1EZ

declare under our sole responsibility that the product

type 07281

Serial Nº ..............................................

to which this declaration relates is in conformity with the following standards or other formative documents

EN292 part 1 and part 2

ISO 8662 part 1 and part 7

ISO 3744 and PNEUROP test code PN8TC1

ISO PREN792 part 6

following the provisions of the Machine Directive 98/37/EC

This box contains a power tool which is in conformity with Machines Directive

98/37/EC. The ‘Declaration of Conformity’ is contained within.

Welwyn Garden City - date of issue A. Seewraj

Product Engineering Manager - Automation Tools

Avdel

An Acument'" Global Technologies Company

AUSTRALIA

Acument Australia Pty Ltd.

891 Wellington Road

Rowville, Victoria 3178

Tel: +61 3 9765 6400

Fax: +61 3 9765 6445

CANADA

Avdel Canada, a Division of Acument

Canada Limited

87 Disco Road

Rexdale

Ontario M9W 1M3

Tel: +1 416 679 0622

Fax: +1 416 679 0678

CHINA

Acument China Ltd.

RM 1708, 17/F., Nanyang Plaza,

57 Hung To Rd., Kwun Tong

Hong Kong

Tel: +852 2950 0631

Fax: +852 2950 0022

FRANCE

Avdel France S.A.S.

33 bis, rue des Ardennes

BP4

75921 Paris Cedex 19

Tel: +33 (0) 1 4040 8000

Fax: +33 (0) 1 4208 2450

GERMANY

Avdel Deutschland GmbH

Klusriede 24

30851 Langenhagen

Tel: +49 (0) 511 7288 0

Fax: +49 (0) 511 7288 133

ITALY

Avdel Italia S.r.l.

Viale Lombardia 51/53

20047 Brugherio (MI)

Tel: +39 039 289911

Fax: +39 039 2873079

JAPAN

Acument Japan Kabushiki Kaisha

Center Minami SKY,

3-1 Chigasaki-Chuo, Tsuzuki-ku,

Yokohama-city, Kanagawa Prefecture

Japan 224-0032

Tel: +81 45 947 1200

Fax: +81 45 947 1205

SINGAPORE

Acument Asia Pacific (Pte) Ltd.

#05-03/06 Techlink

31 Kaki Bukit Road 3

Singapore, 417818

Tel: +65 6840 7431

Fax: +65 6840 7409

SOUTH KOREA

Acument Korea Ltd.

212-4, Suyang-Ri,

Silchon-Eup, Kwangju-City,

Kyunggi-Do, Korea, 464-874

Tel: +82 31 798 6340

Fax: +82 31 798 6342

SPAIN

Avdel Spain S.A.

C/ Puerto de la Morcuera, 14

Poligono Industrial Prado Overa

Ctra. de Toledo, km 7,8

28919 Leganes (Madrid)

Tel: +34 (0) 91 3416767

Fax: +34 (0) 91 3416740

UNITED KINGDOM

Avdel UK Limited

Pacific House

2 Swiftfields

Watchmead Industrial Estate

Welwyn Garden City

Hertfordshire

AL7 1LY

Tel: +44 (0) 1707 292000

Fax: +44 (0) 1707 292199

USA

Avdel USA LLC

614 NC Highway 200 South

Stanfield,

North Carolina 28163

Tel: +1 704 888-7100

Fax: +1 704 888-0258

© Av

de

l UK Lim

ite

d

2007

Manual No.

Issue

Change Note No.

07900-00658

B

07/325

www.avdel-global.com

Manual No. Issue Change Note No.

07900-00658

B07/325

© Avdel UK Limited 2007

AUSTRALIA

Acument Australia Pty Ltd.

891 Wellington Road

Rowville, Victoria 3178

Tel: +61 3 9765 6400

Fax: +61 3 9765 6445

Email: [email protected]

CANADA

Avdel Canada, a Division of Acument

Canada Limited

87 Disco Road

Rexdale

Ontario M9W 1M3

Tel: +1 416 679 0622

Fax: +1 416 679 0678

Email: [email protected]

CHINA

Acument China Ltd.

RM 1708, 17/F., Nanyang Plaza,

57 Hung To Rd., Kwun Tong

Hong Kong

Tel: +852 2950 0631

Fax: +852 2950 0022

Email: [email protected]

FRANCE

Avdel France S.A.S.

33 bis, rue des Ardennes

BP4

75921 Paris Cedex 19

Tel: +33 (0) 1 4040 8000

Fax: +33 (0) 1 4208 2450

Email: [email protected]

GERMANY

Avdel Deutschland GmbH

Klusriede 24

30851 Langenhagen

Tel: +49 (0) 511 7288 0

Fax: +49 (0) 511 7288 133

Email: [email protected]

ITALY

Avdel Italia S.r.l.

Viale Lombardia 51/53

20047 Brugherio (MI)

Tel: +39 039 289911

Fax: +39 039 2873079

Email: [email protected]

JAPAN

Acument Japan Kabushiki Kaisha

Center Minami SKY,

3-1 Chigasaki-Chuo, Tsuzuki-ku,

Yokohama-city, Kanagawa Prefecture

Japan 224-0032

Tel: +81 45 947 1200

Fax: +81 45 947 1205

Email: [email protected]

SINGAPORE

Acument Asia Pacific (Pte) Ltd.

#05-03/06 Techlink

31 Kaki Bukit Road 3

Singapore, 417818

Tel: +65 6840 7431

Fax: +65 6840 7409

Email: [email protected]

SOUTH KOREA

Acument Korea Ltd.

212-4, Suyang-Ri,

Silchon-Eup, Kwangju-City,

Kyunggi-Do, Korea, 464-874

Tel: +82 31 798 6340

Fax: +82 31 798 6342

Email: [email protected]

SPAIN

Avdel Spain S.A.

C/ Puerto de la Morcuera, 14

Poligono Industrial Prado Overa

Ctra. de Toledo, km 7,8

28919 Leganés (Madrid)

Tel: +34 (0) 91 3416767

Fax: +34 (0) 91 3416740

Email: [email protected]

UNITED KINGDOM

Avdel UK Limited

Pacific House

2 Swiftfields

Watchmead Industrial Estate

Welwyn Garden City

Hertfordshire

AL7 1LY

Tel: +44 (0) 1707 292000

Fax: +44 (0) 1707 292199

Email: [email protected]

USA

Avdel USA LLC

614 NC Highway 200 South

Stanfield,

North Carolina 28163

Tel: +1 704 888-7100

Fax: +1 704 888-0258

Email: [email protected]

www.avdel-global.com

Table of contents

Other Avdel Power Tools manuals

Popular Power Tools manuals by other brands

MK Diamond Products

MK Diamond Products MK-370 Owner's manual & operating instructions

Milwaukee

Milwaukee 1680-20 Operator's manual

PCB Piezotronics

PCB Piezotronics 027137-07051 Installation and operating manual

Weston

Weston 05-0101 manual

HIKOKI

HIKOKI CJ 18DA Handling instructions

Munsch

Munsch GMAK-420 operating instructions