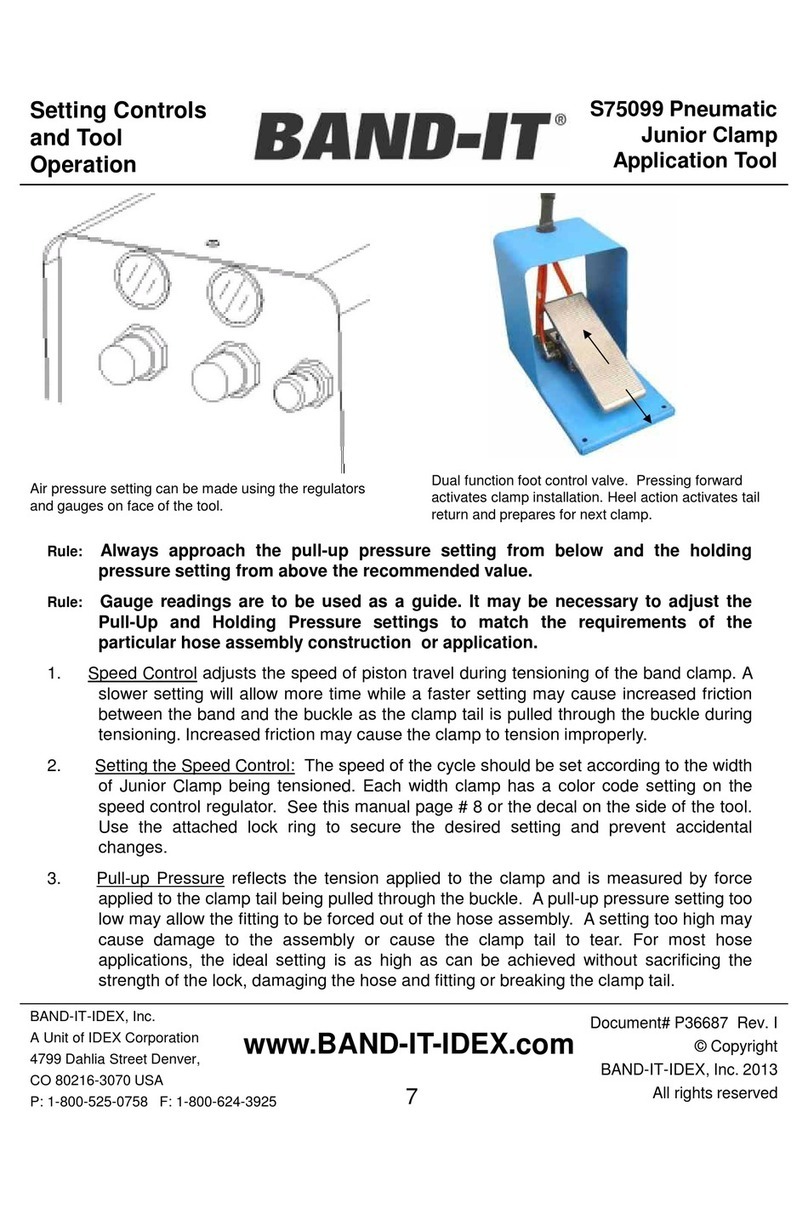

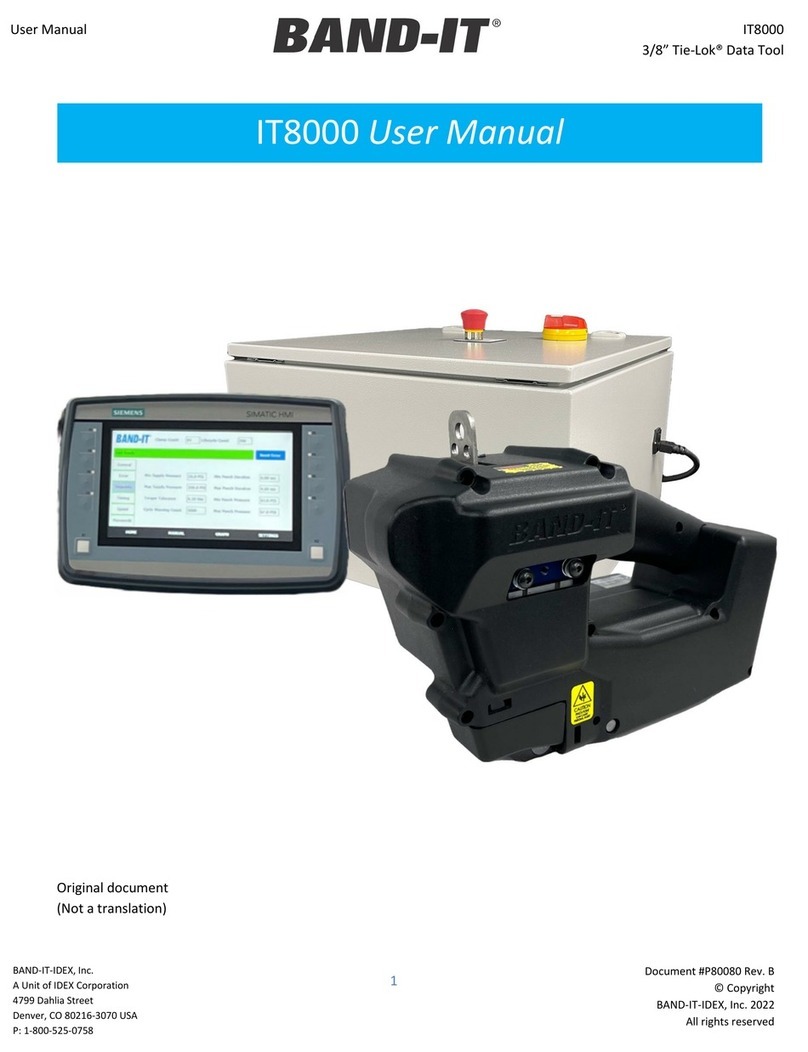

GRSM17

Pneumatic

Center Punch

Tool

Problem Probable Cause Correction

1. Sharp or scarred edges on clamp. Metal

deposits on underside of tail at buckle edge.

Loose or broken cutter blade / backing

plate.

Make certain all fasteners are tight. Replace

any broken or chipped blades. Cutter Blade

and Backing each have a dual edge design

and can be rotated to unused side one time

before being replaced as a set.

2. Tail is broken at approximately 45°. Clamp

material stretched or thinned at break.

Pull-up pressure set too high Reduce pull-up pressure. Apply clamp and

adjust if necessary.

Clamp not inserted properly. Make sure clamp is straight and level w hen

inserting.

Band gripper pin loose Tighten gripper pin set screw .

Pull-up cylinder needs lubrication Check filter / lubricator and add oil if

necessary.

Loose cutter blade on head Check and tighten all hardw are.

Clamp tail is too long and the end of stroke

has been reached.

Reverse f oot pedal and pull hose assembly

back to expose clamp tail. Cut off excess

clamp tail and resume.

Center Punch head not connected after

previous maintenance.

Connect cut-of f cylinder w ith provided quick

release pin assembly.

Broken or w orn teeth on gripper Replace gripper.

Pressure settings too high Settings are a guide, it may be necessary to

low er pressure settings.

3. Clamp tensions in a jerky manner.

5. Clamp tail slips in band gripper lever.

4. Clamp pulls but does not lock.

Trouble Shooting

Guide

Document# P47050 Rev. -

© Copyright

BAND-IT-IDEX, Inc. 2008

All rights reserved

www.BAND-IT-IDEX.com

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

7

Gripper springs stretched out Replace springs.

Tripper plate stuck due to dirt or lack of

lubrication

Check and clean/or re-lubricate the tripper

plate.

6. Clamp tail folded and caught inside tool Clamp tail catches as heel of f oot pedal is

depressed and cylinder is returned for next

clamp cycle.

1) Re-cycle tool 2) Operate the tool to bring the

piston to about half w ay. 3) To remove the

clamp tail, reach under piston rod and locate

band gripper lever. 4) Rotate lever tow ard

clamp head and allow tail to f all f rom tool. If tail

remains stuck, use pliers to grasp tail and

carefully remove. Never position fingers

anywhere b ut on gripper lever!

Loose or broken cutter blade Tighten or replace cutter blade.

CP Head disconnected Connect CP Head assembly.

Low pressure on incoming air supply Check and adjust incoming air supply. Note:

Minimum supply pressure is 70 PSI.

Air leak f rom loose connection or w orn

parts

Remove tool cover and tighten loose

connections and / or replace w orn parts.

Speed Control regulator set too low Adjust to Blue setting per instructions.

Previous clamp tail has not yet been

removed

Remove clamp tail f rom tool.

Tripper plate may be broken or binding. Remove, inspect, clean and lubricate or

replace tripper plate.

7. Tool doesn't cut-off clamp.

8. Tool takes excessive time f or clamp

pull-up.

9. Clamp tail cannot be inserted into tool.