BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P07986 Rev. F

© Copyright

BAND-IT-IDEX, Inc. 2011

All rights reserved

www.BAND-IT-IDEX.com

Page 6 of 14

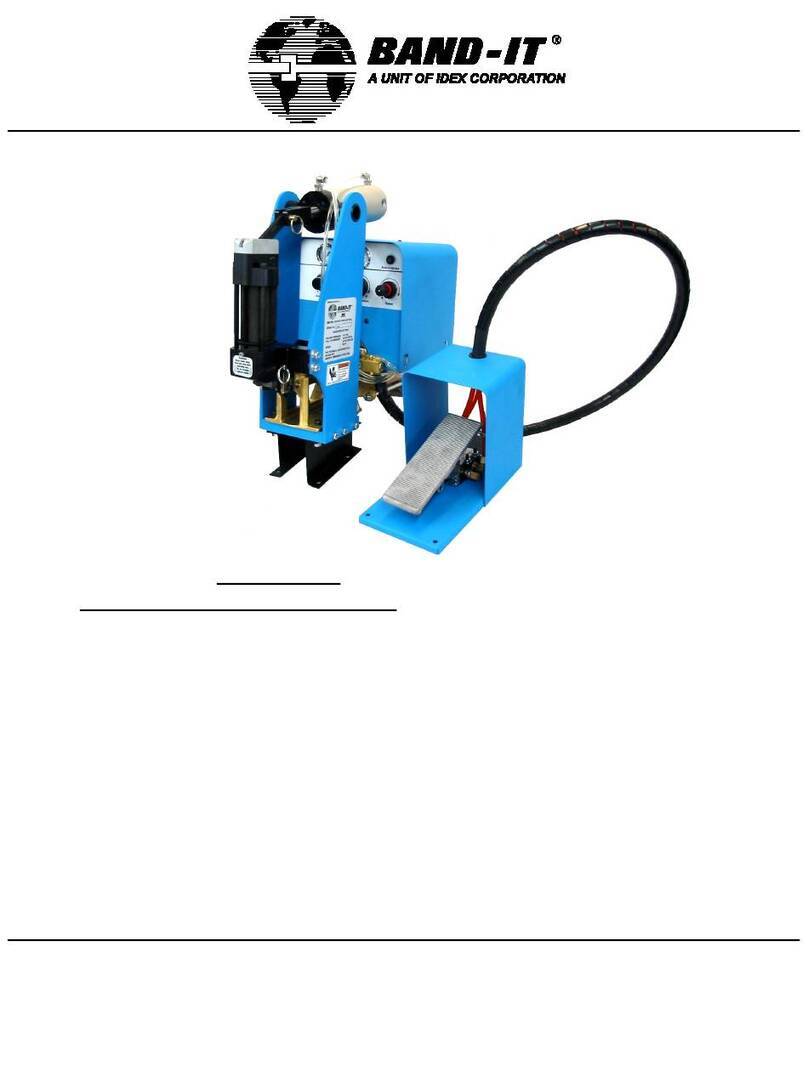

UL4000-B

UL4000-B2

Ultra-Lok

Tool

Parts List

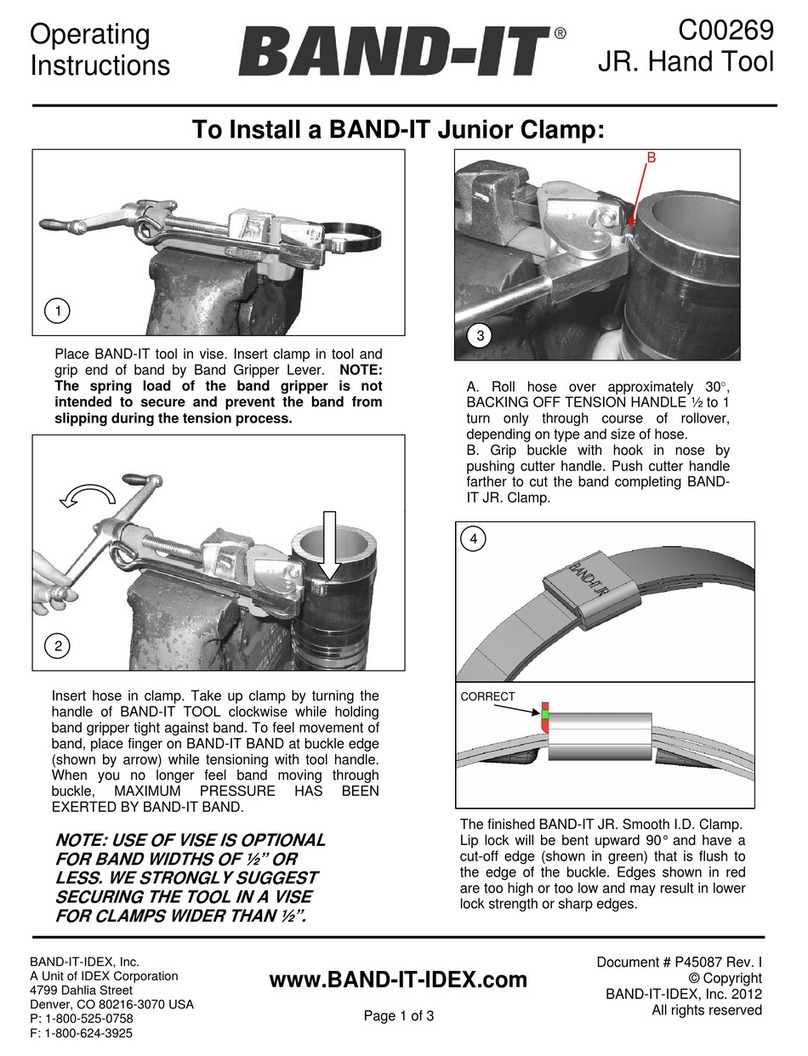

Apply Item 31 (Super Lube) to:

Item 4 (Cut-off Cam)

Item 3 (Cutter Knife) at contact point with item 1 (Tool Head)

Item 26 (Spring) before installation

Apply Item 32 (Grease) to:

Item 7 (Tension Screw) threads and grooved end

Item 2 (Cutter Blade) counter-bore only, after item 14 (Bearing Tip) has been installed.

Tighten the following:

Item 23 (#10-32 Screws)

to 60 – 70 in-lbs.

Item 22 (1/4-28 Screws)

to 90 – 110 in-lbs.

Adjust Item 24 (Plunger) for

positive detent action when

item 6 (Handle) is actuated.

Item Part Number Qty Description

1 M00587 1 Tool Head, Fin. UL

2 M09787 1 Cutter Blade, UL

3 M08687 1 Cutter Knife, UL

4 M08987 1 Cam, Cut-off, UL

5 M09087 1 Tension Block, Mach., UL

6 UL1219 1 Handle Assembly:

Includes Handle, Handle Grip, and Pins

7 M00987 1 Tension Screw, Fin.

8 M08887 1 Gripper, UL

9 M01787 1 Plate, Back, Cast/Fin.

10 M09187 1 Gripper Guide, UL

11 M02387 1 Plate, Release, cast/fin.

12 M00287 1 Roller, Cut-off, Fin.

13 M01388 2 Pin, .187 Dia X 1.50 Long, Fin.

14 M05387 1 Bearing Tip, Fin.

15 M06587 1 Ball, ¼” Diameter

16 M02287 1 Tip, Load Bearing, Fin.

17 M04387 1 Tripper Bracket, Cast/Fin.

18 M07387 1 Body, Left, Finished, UL

19 M07487 1 Body, Right, Finished, UL

20 M07587 2 Wear Plate, Fin.

21 M05787 2 Screw, Socket Head Cap, ¼ X 1”

22 J67287 4 Screw, Socket Head Cap, ¼ X ½”

23 M06187 4 Screw, Socket Head Cap, #10-32 X 3/8”

24 M02487 2 Screw, Spring Plunger, ¼-20

25 A33887 1 Spring, Compression, .180 X .813 Long

26 A53587 2 Spring, Compression, .300 X 1.00 Long

27 M01487 1 Pin, Dowel, ¼ Dia X 1.50 Long

28 M08187 4 Washer, .128 ID X .238 OD

29 M08087 4 Rivet, Blind, .125 X .328 Long

30 M07987 2 Threaded Insert, #10-32

31 I16387* - Lubricant, Super Lube w/ Teflon

32 C23199 - Lubricant, Moly, Syringe

33 M09887 1 Shear Plate, ¾”, UL

34 M09387 1 Shear Plate, UL, ½” (Optional)

35 M06287 1 Adapter, UL4000-B

36 M08388 1 Collar, Adapter, UL4000-B

* Permatex P/N: 82325 or Equivalent