TABLE OF CONTENTS

SAFETY GUIDELINES AND WARRANTY.................................................................................................4

SAFETY INSTRUCTIONS...........................................................................................................................................4

WARRANTY.............................................................................................................................................................4

SAFETY SIGNS..........................................................................................................................................................5

GUARDING AND INTERLOCKS.................................................................................................................................6

PRODUCT SAFETY LOCATIONS................................................................................................................................7

OVERVIEW.........................................................................................................................................8

QUICK START OVERVIEW........................................................................................................................................8

ENVIRONMENT..................................................................................................................................9

TRANSPORTATION, STORAGE, HANDLING .............................................................................................................9

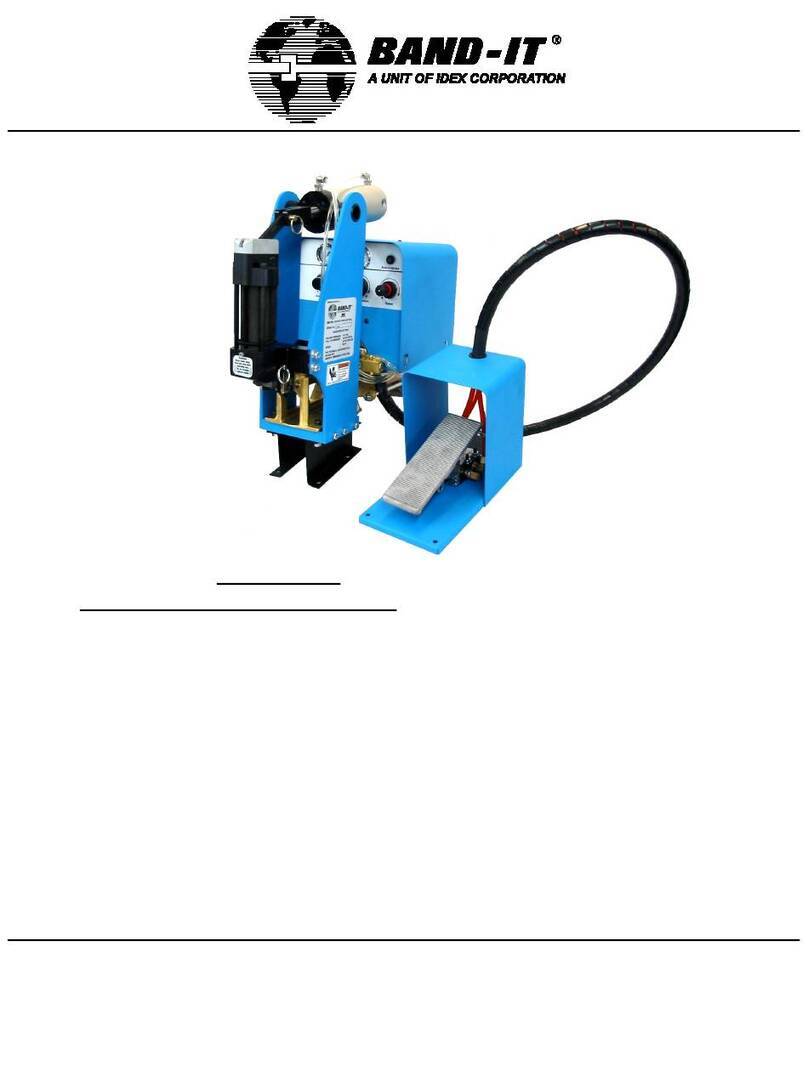

TOOL SETUP.....................................................................................................................................10

OPERATING REQUIREMENTS............................................................................................................................... 10

PART DESCRIPTIONS AND LOCATIONS ................................................................................................................ 11

INSTALLATION TOOL DIMENSIONS...................................................................................................................... 13

CONTROLLER ENCLOSURE DIMENSIONS............................................................................................................. 14

CONNECTING THE TOOL TO CONTROLLER.......................................................................................................... 15

CONNECTING THE HMI TO CONTROLLER............................................................................................................ 16

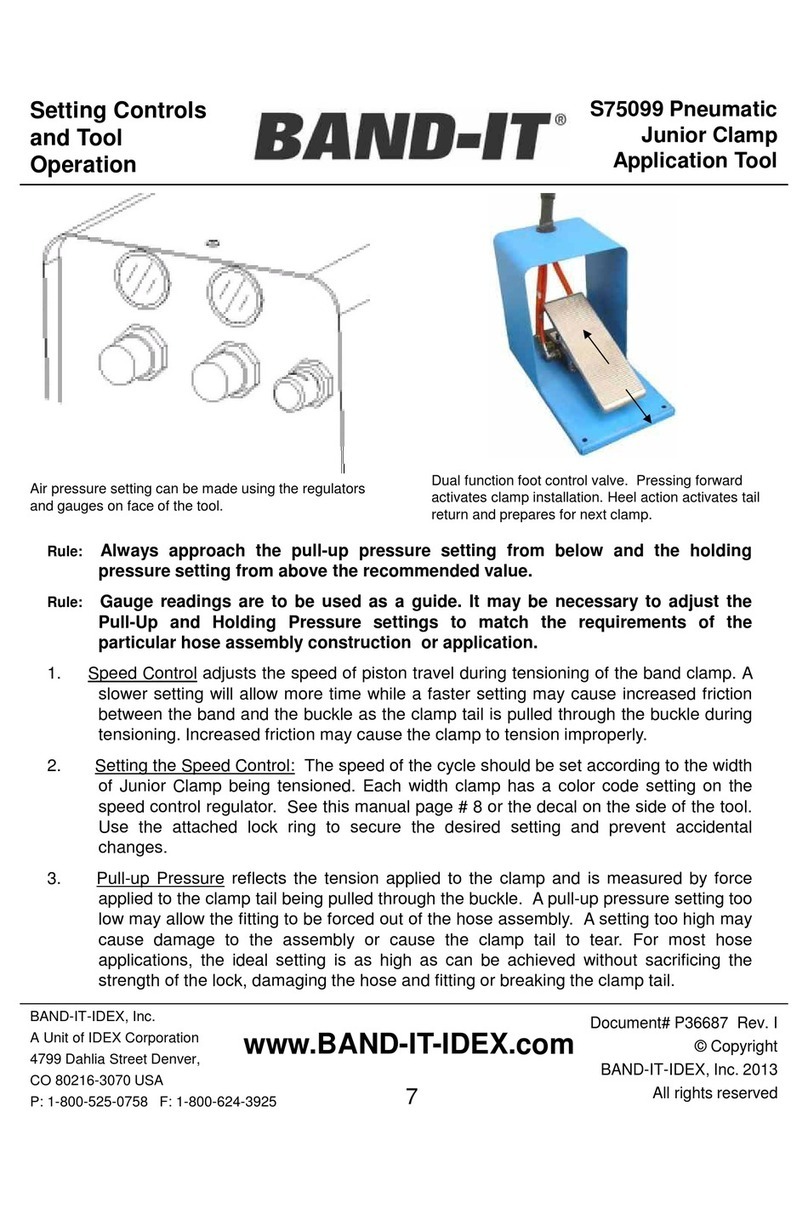

AIR SYSTEM SETUP AND PRESSURE SETTINGS .................................................................................................... 17

AIR FLOW TIMING................................................................................................................................................ 18

FACTORY PROGRAM SETTINGS ........................................................................................................................... 31

SYNCING TOOL TO CONTROLLER......................................................................................................................... 19

OPERATION .....................................................................................................................................20

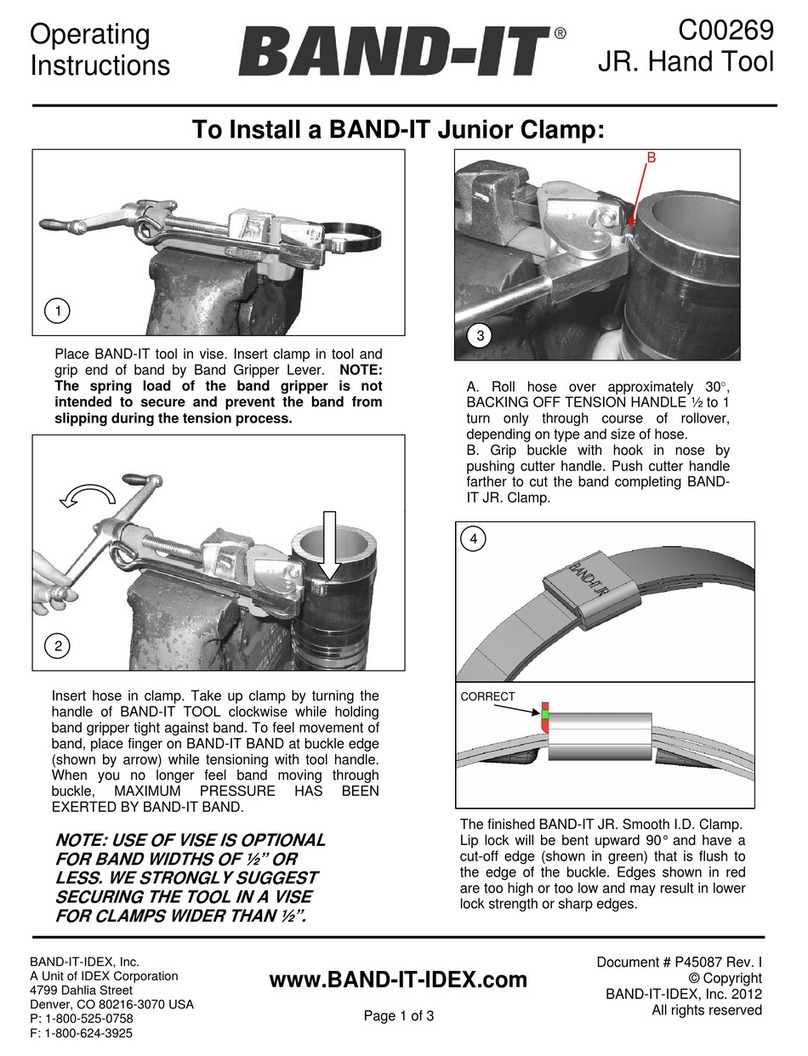

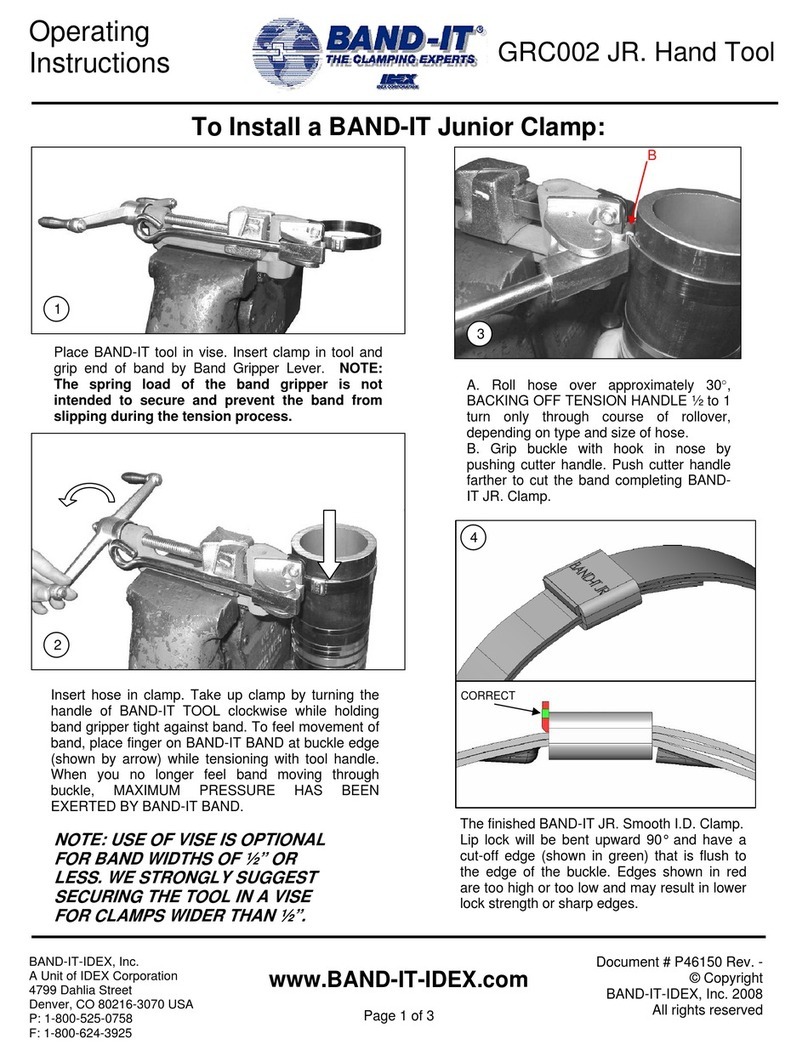

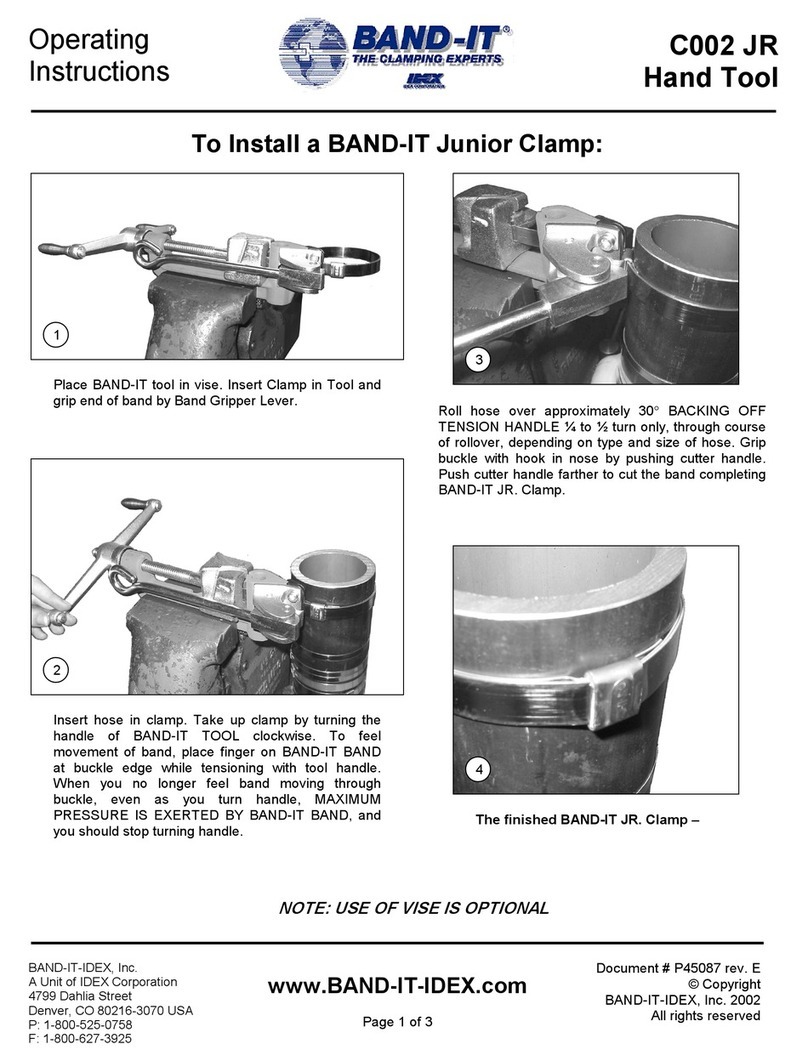

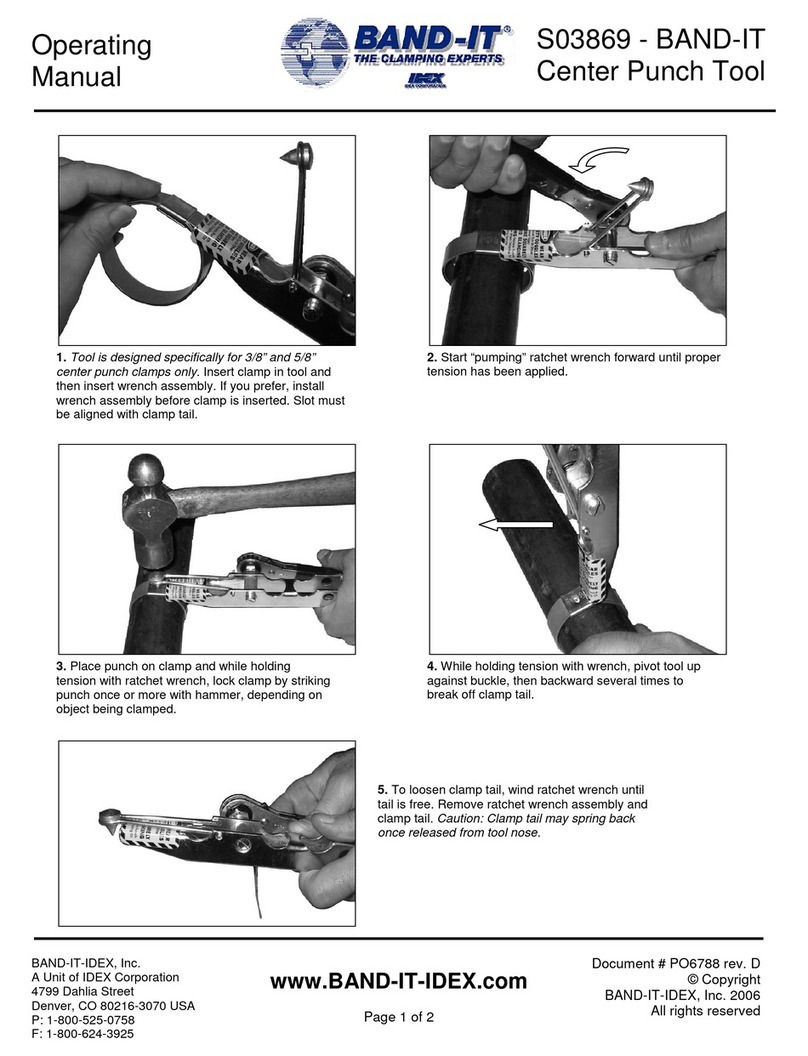

TIE INSTALLATION PROCEDURE........................................................................................................................... 20

TOOL OPERATION................................................................................................................................................ 20

TIE INSPECTION ................................................................................................................................................... 21

CLAMP PLACEMENT ............................................................................................................................................ 21

MOUNTING AND FIXTURING............................................................................................................................... 22

TOOL ROTATION.................................................................................................................................................. 25

CENTER OF GRAVITY............................................................................................................................................ 26

MOUNTING EXAMPLES........................................................................................................................................ 27