911000099Y Rev T SCP 250 Introduction iii

CONTENTS

SECTION 1 •GENERAL INFORMATION ................................................................................................ 1-1

INTRODUCTION................................................................................................................................. 1-1

FEATURES ......................................................................................................................................... 1-1

APPLICATION .................................................................................................................................... 1-1

Generator Peaking Application (SCP 250-G)............................................................................... 1-1

Synchronous Motor Application (SCP 250-M).............................................................................. 1-1

Isolated Bus Applications ............................................................................................................. 1-2

PART NUMBERS................................................................................................................................ 1-2

SPECIFICATIONS .............................................................................................................................. 1-2

Voltage Sensing and Input Power ................................................................................................ 1-2

Current Sensing............................................................................................................................ 1-2

Output Signal................................................................................................................................ 1-2

Enable Contact ............................................................................................................................. 1-2

Control Accuracy .......................................................................................................................... 1-2

Type Tests .................................................................................................................................... 1-3

UL Recognition ............................................................................................................................. 1-3

GOST-R Certification.................................................................................................................... 1-3

Operating Temperature ................................................................................................................ 1-3

Weight........................................................................................................................................... 1-3

SECTION 2 •CONTROLS ........................................................................................................................ 2-1

CONTROLS ILLUSTRATION AND DESCRIPTION........................................................................... 2-1

SECTION 3 •FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

INTRODUCTION................................................................................................................................. 3-1

INPUTS ............................................................................................................................................... 3-1

COMPARATOR AND ERROR AMPLIFIER........................................................................................ 3-1

VOLTAGE LIMITING........................................................................................................................... 3-2

CONTROL RELAY.............................................................................................................................. 3-2

SECTION 4 •INSTALLATION .................................................................................................................. 4-1

GENERAL ........................................................................................................................................... 4-1

MOUNTING......................................................................................................................................... 4-1

CONNECTIONS.................................................................................................................................. 4-3

Interconnection Diagrams............................................................................................................. 4-3

Remote Control of the SCP 250 .................................................................................................4-19

SECTION 5 •OPERATION....................................................................................................................... 5-1

INTRODUCTION................................................................................................................................. 5-1

GENERATOR APPLICATIONS .......................................................................................................... 5-1

Preliminary Adjustments for Var Control ...................................................................................... 5-1

Preliminary Adjustments for Power Factor Control ...................................................................... 5-2

MOTOR APPLICATIONS.................................................................................................................... 5-3

Preliminary Adjustments for Power Factor Control ...................................................................... 5-3

Figures

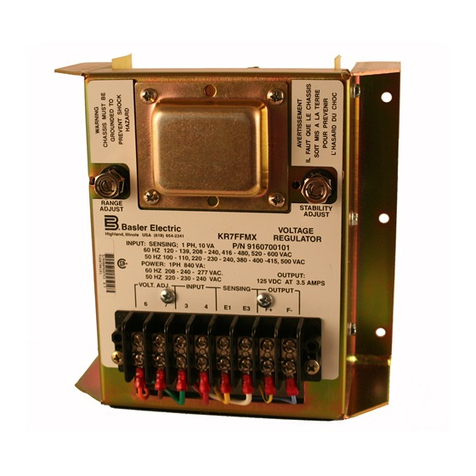

Figure 2-1. SCP 250 Controls ................................................................................................................... 2-1

Figure 3-1. SCP 250 Function Block Diagram .......................................................................................... 3-1

Figure 4-1. SCP 250 Outline and Drilling Dimensions .............................................................................. 4-2

Figure 4-2. AVC63-12/AVC-125-10 and SCP 250-G Connections ........................................................... 4-4

Figure 4-3. KR-F/KR-FF and SCP 250-G Connections............................................................................. 4-5

Figure 4-4. KR-F/KR-FF and SCP 250-M Connections ............................................................................ 4-6

Figure 4-5. MVC 236, RA-70, AND SCP 250-M Connections .................................................................. 4-7

Figure 4-6. SR-A and SCP 250-G Connections ........................................................................................ 4-8

Figure 4-7. SR-A and SCP 250-M Connections........................................................................................ 4-9

Figure 4-8. SR-E/SR-F/SR-H and SCP 250-G Connections................................................................... 4-10

Figure 4-9. SR-E/SR-F/SR-H and SCP 250-M Connections .................................................................. 4-11

Figure 4-10. SSE and SCP 250-G Connections ..................................................................................... 4-12