Contents

General Information .................................................................................................................................... 1

Specifications ............................................................................................................................................ 1

Power Input*.......................................................................................................................................... 1

Output Rating......................................................................................................................................... 1

Input Sensing Voltage*(NEMA Standard) ............................................................................................ 1

Field Resistance .................................................................................................................................... 1

Temperature .......................................................................................................................................... 2

Vibration ................................................................................................................................................. 2

Mounting ................................................................................................................................................ 2

Weight.................................................................................................................................................... 2

Overall Dimensions................................................................................................................................ 2

Optional Features ...................................................................................................................................... 2

Accessories ............................................................................................................................................... 2

Model and Style Number Description........................................................................................................ 3

Principles of Operation............................................................................................................................... 5

Functional Circuits ..................................................................................................................................... 5

Application Information .............................................................................................................................. 5

Starting Large Motors or Providing Fault Current for Selective Breaker Tripping ................................. 5

Parallel Compensation .............................................................................................................................. 6

Reactive Droop Compensation (Droop)................................................................................................. 6

Reactive Differential Compensation (Cross-Current) ............................................................................ 6

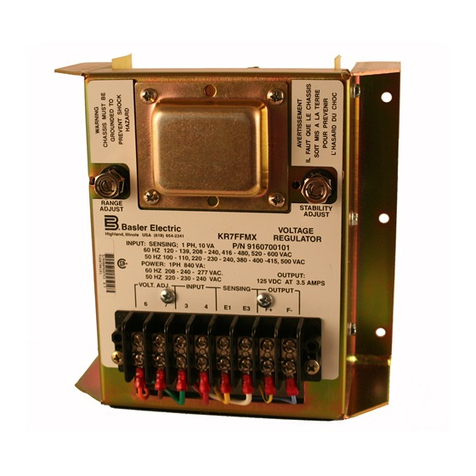

Installation ................................................................................................................................................... 9

Mounting .................................................................................................................................................... 9

Interconnection ........................................................................................................................................ 11

General ................................................................................................................................................ 11

Regulator Sensing (Terminals E1, E2, and E3)................................................................................... 11

Field Power (Terminals F+ and F–) ..................................................................................................... 13

Interconnecting Regulator with Brush-Type Rotary Exciters (Terminal A–) ........................................ 13

Input Power (Terminals 3 and 4) ......................................................................................................... 13

Parallel Compensation (Terminals 1 and 2) ............................................................................................ 14

Reactive Droop Compensation (Droop) .................................................................................................. 14

Reactive Differential Compensation (Cross Current) .............................................................................. 14

Wiring....................................................................................................................................................... 18

Operation ................................................................................................................................................... 19

Operation at Reduced Speeds ................................................................................................................ 19

Voltage Shutdown ................................................................................................................................... 19

Adjustments............................................................................................................................................. 19

Stability Adjustment R4........................................................................................................................ 20

Generator Voltage Adjust Rheostat R1 ............................................................................................... 20

Nominal Voltage Range Set Adjust R3................................................................................................ 20

Wiring....................................................................................................................................................... 20

Initial Operation ....................................................................................................................................... 20

Single Unit Operation (No Load).......................................................................................................... 20

Instability .............................................................................................................................................. 21

Field Flashing .......................................................................................................................................... 21

Parallel Operation.................................................................................................................................... 22

Preliminary Instructions ....................................................................................................................... 22

Preliminary Operation .......................................................................................................................... 22

Conditions Necessary for Paralleling................................................................................................... 22

Metering ............................................................................................................................................... 22

Sequence of Operation (Parallel) ........................................................................................................ 23

Maintenance .............................................................................................................................................. 25

Preventive Maintenance .......................................................................................................................... 25

Corrective Maintenance........................................................................................................................... 25

Warranty and Repair Service .................................................................................................................. 25