iii

CONTENTS

SECTION 1.0 GENERAL INFORMATION.....................................................................1-1

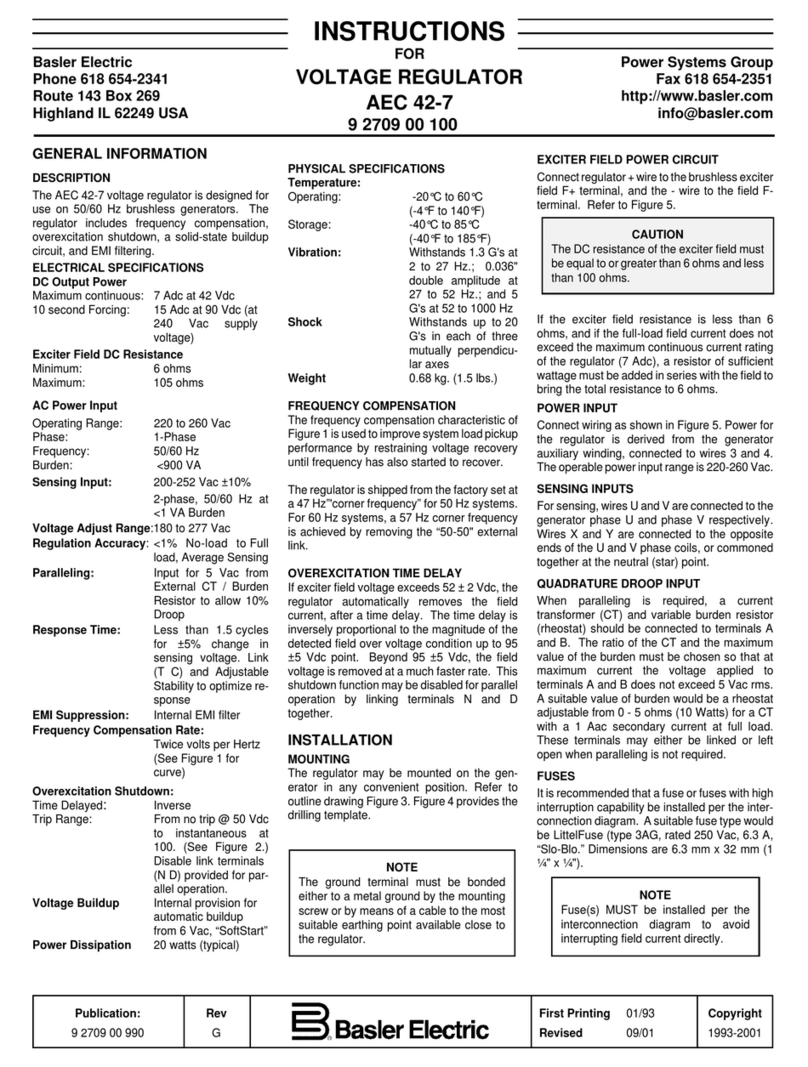

1.1 Description...............................................................................................1-1

1.2 Specifications...........................................................................................1-1

Electrical Specifications

...........................................................................1-1

Physical Specifications

............................................................................1-2

1.3 Optional Features .................................................................................... 1-2

1.4 Accessories .............................................................................................1-3

1.5 Model Number Description and Selection ...............................................1-3

Typical Model Number

.............................................................................1-4

Model Number Designations

....................................................................1-4

SECTION 2.0 PRINCIPLES OF OPERATION...............................................................2-1

2.1 Functional Circuits ................................................................................... 2-1

Overall Block Diagram

.............................................................................2-1

2.2 Application Information ............................................................................ 2-1

2.3 Parallel Compensation............................................................................. 2-2

SECTION 3.0 INSTALLATION....................................................................................... 3-1

3.1 Mounting..................................................................................................3-1

Outline Drawing

.......................................................................................3-1

3.2 Interconnection ........................................................................................ 3-2

Voltage Adjust Potentiometer P/N (03456)

..............................................3-2

Paralleling Potentiometer P/N (03469)

....................................................3-2

Brush Type Rotary Exciter Interconnection

.............................................3-5

Brushless Type Rotary Exciter (or Static Exciter)

Interconnection ........................................................................................ 3-6

3.3 Parallel Compensation............................................................................. 3-6

3.4 Reactive Droop Compensation (Droop)................................................... 3-7

3.5 Reactive Droop Compensation (Cross-Current)...................................... 3-7

Reactive Differential (Cross-Current) Compensation CT

Interconnection ........................................................................................

3-8

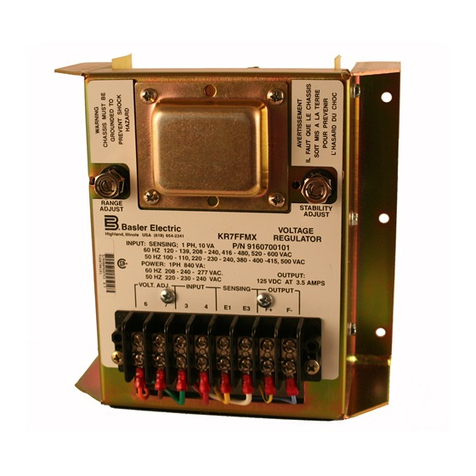

Top View of Voltage Regulator................................................................

3-8

SECTION 4.0 OPERATION............................................................................................ 4-1

4.1 General....................................................................................................4-1

4.2 Operation at Reduced Speeds ................................................................4-1

4.3 Voltage Shutdown....................................................................................4-1

4.4 Adjustments............................................................................................. 4-2

4.5 Wiring .....................................................................................................4-2

4.6 Initial Operation........................................................................................4-2

4.7 Field Flashing........................................................................................... 4-4

4.8 Parallel Operation.................................................................................... 4-4

SECTION 5.0 MAINTENANCE, REPLACEMENT PARTS AND

TROUBLESHOOTING........................................................................... 5-1

5.1 Preventive Maintenance .......................................................................... 5-1

5.2 Corrective Maintenance...........................................................................5-1

Operational Test

......................................................................................5-1

5.3 Replacement Parts..................................................................................5-2

Component Location and Identification

....................................................5-2

SR4A Replacement Parts

........................................................................5-3