CAUTION

Do not flash the field with the

generator in motion. Regulator

damage may result.

CAUTION

The factory calibration (FAC CAL)

adjustment is intended for use by

factory technicians only. The

following procedure can be used if

the factory calibration has been

disturbed.

F2 Field -

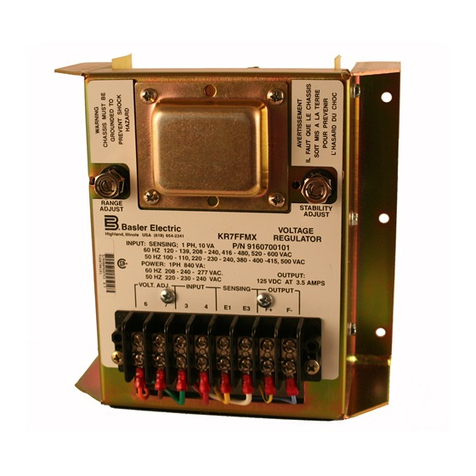

Table 2. Internal Adjustments

Adjust. Adjustment.

Description

DRP Voltage Droop Adjust

FAC CAL FAC CAL is a factory voltage

adjust range calibration. No

customer adjustment is

required.

VLT ADJ Multi-Turn Voltage Adjust

UF Underfrequency Knee Adjust

STB Stability Adjust

OPERATION

General

Table3providessystemstart-upproceduresfor

the AVC63-12 and AVC125-10 Voltage Reg-

ulators.Symptomsofproblemsoccurringduring

start-up that arise from incorrect regulator

adjustment and certain generator system

problems that resemble faulty regulation are

included together with possible solutions.

Simplifying the system by eliminating

components, such as remote adjust poten-

tiometers and other non-essential items can be

helpful in the troubleshooting process. Ad-

justments, options, and an operational test are

included in the paragraphs after the table.

Preliminary Set-Up

Topreventdamagetotheregulator,ensurethat

the regulator has been installed and connected

in accordance with the paragraphs in

Instal-

lation

and

Connections

before proceeding with

the system start-up.

System Start-Up

Refer to Table 3 for system start-up.

ADJUSTMENTS

Field Flashing

When the regulator is operated with the

generator for the first time, the polarity of the

residual magnetism may not be correct or of

sufficient magnitude. If generator residual

voltage is less than 6 Vac for the AVC63-12 or

12 Vac for the AVC125-10 at terminals 26,28

and/or 30 shut down the prime mover and

proceed with the following steps:

1. With the prime mover at rest, apply a dc

source (ungrounded), of not more than 24

Vdc, to terminals F1 (positive) and F2

(negative) in series with a limiting resistor.

Use one (1) ohm of resistance for each volt

from the dc power source with a power

rating of least one (1) watt per ohm.

EXAMPLE: If using a 24 Vdc source, use

a 24-ohm, 24-watt resistor.

2. Allow the field to be flashed for approx-

imatelytensecondsbeforeremovingthedc

source.

3. If voltage build-up does not occur after

performing steps (1) and (2), verify the

polarity of the dc source used in steps (1)

and (2) and re-perform.

Frequency Roll-Off (UF Knee) Adjustment

The underfrequency knee (roll-off) is typically

set below the nominal system frequencies.

When the generators speed falls below the

knee set point of the regulator, generator

voltage is reduce proportional to the speed of

the machine. To adjust the underfrequency

knee, follow the steps below:

(1) Adjust the generator frequency for nominal

frequency (50, 60, or 400 Hz).

(2) Adjust the underfrequency potentiometer

(UF) CCW.

(3) AdjusttheVoltageAdjustpotentiometerfor

nominal generator voltage.

(4) Adjust the underfrequency potentiometer

(UF) CW until the voltage begins to decrease.

(5) Adjust the underfrequency potentiometer

(UF) CCW until the voltage just returns to the

value set in Step 3.

(6) The underfrequency knee is now set just

belowthenominaloperatingfrequency. Further

rotationintheCCWdirectionwilllowertheknee

frequency set point at which underfrequency

compensation begins.

(7) Connecting a jumper from terminal 8 to

terminal 6a will provide an underfrequency

slope of 1 P.U. V/Hz. No connection to

terminal8willresult inanunderfrequency slope

of 2 P.U. V/Hz. The slope can also be selected

on the 400Hz models. However, the actual

V/Hz curve is approximately 1 P.U. or 2 P.U.

depending if the terminal 8 is jumpered to 6a or

not.

Stability (STB) Adjustment

An oscilloscope or other voltage-recording

device should be used if an optimal stability

setting is desired. Adjust the stability setting

with the generator at no load. Good

response can be obtained with the following

procedure.

(1) Rotation of the front panel STB control in

theclockwise(CW)directionwillslowresponse

time.

(2) Rotation of the front panel STB control in

the counter-clockwise (CCW) direction will

speed response time. If rotated too far CCW,

the generator voltage may oscillate (hunt).

(3) Rotate the front panel STB control CCW

until the system just begins to oscillate and

then rotate CW just past the point where

oscillation occurred. Apply various amounts of

loadstodetermineproperstabilityperformance.

Voltage (VLT ADJ) Adjustment

(1) Installation of a jumper across terminals 4

and 7allows the internal (front panel) VLT ADJ

adjustment to vary the generator nominal

voltage over the operating range.

(2) Remove the jumper between terminals 4

and 7and connect a 10k ohm external voltage

adjust potentiometer across terminals 6a and 7

to allow operation of the external voltage adjust

potentiometer. Theinternalvoltageadjustment

should be set fully CW for proper operation of

the external adjustment. It should be noted, as

the external potentiometer resistance in-

creases, generator voltage also increases.

Factory Calibration (FAC CAL) Adjustment

(1) With the voltage regulator operating on a

generator, adjust the calibration potentiometer

fully CCW and the external voltage adjust

potentiometer fully CW. Adjust the FAC CAL

potentiometer CW until the generator voltage

reaches the desired maximum voltage setting.

The unit is calibrated and the calibration

potentiometer can be sealed.

Parallel Droop Compensation

Variableparalleldroopcompensationlevels can

be obtained by adjusting the droop poten-

tiometer. CW rotation increases the amount of

droop for a given condition.

Line Drop Compensation

When the sensing input CT connections are

swapped to provide LDC, the droop adjustment

becomes the LDC adjustment.

OPTIONS

The AVC63-12 and AVC125-10 may be

equipped with the following options to enhance

operational characteristics. Characteristics of

these options are defined in the following para-

graphs.

Remote Voltage Adjust

Connect a 10k ohm, 2 watt potentiometer from

terminals 6a to 7, remove the jumper from

terminal 4 to 7 and adjust the internal voltage

adjustpotentiometerfullyCWtoallowoperation

of a remote voltage adjust.

Excitation Disable

This option provides for disabling of the

excitation system by removal ofpower from the

voltage regulator. A switch removing voltage

from terminals 26, 28 and/or 30 will remove

power.

Excitation Limiter

This EL200 option provides an initial fast acting

limit of the field current at a pre-selected level.

Once the field current has changed to the

selected level, the output provides a signal to

the regulator to change the excitation.

Var/PF Control

This option allows the AVC63-12 and the

AVC125-10toregulatethevarandpowerfactor

while the generator is connected to an infinite

orutility bus. The var/PF option(Model Number

SCP250G-50 for 50-hertz operation or

SCP250G-60 for 60-hertz operation)supplies a

dc signal into the AVC63-12 and AVC125-10

terminals2and3to regulate theSCP250 var or

power factor setting. (See Figure 7 for inter-

connection diagram.)

Current Boost System

WiththisCBS212option,ifthegeneratoroutput

voltage drops below the preset operation point

due to a short or large motor starting, the

current boost function detects the voltage drop.

The function then provides full current boost to

the generator exciter until the voltage returns to

a level just above the operation point.

Manual Voltage Control

This option provides amanualback-up channel

for manually controlling the generator output

duringgeneratorstart-upandcommissioningor

in the unlikely event that the voltage regulator

should fail. Manual voltage controller model

MVC-112 is suitable for use with the either the

AVC63-12or the AVC125-10voltageregulator.