Benning CM 7 Operating and installation instructions

Other manuals for CM 7

1

Table of contents

Other Benning Test Equipment manuals

Benning

Benning IT 130 Manual

Benning

Benning PV 2 User manual

Benning

Benning IT 130 Manual

Benning

Benning DUSPOL analog User manual

Benning

Benning PV 2 User manual

Benning

Benning PV 1-1+ User manual

Benning

Benning DUSPOL digital plus User manual

Benning

Benning DUTEST pro User manual

Benning

Benning PROFIPOL+ User manual

Benning

Benning DUSPOL digital plus User manual

Benning

Benning DUSPOL compact User manual

Benning

Benning TRITEST easy User manual

Benning

Benning PV 1-1+ Manual

Benning

Benning DUTEST User manual

Benning

Benning duspol expert User manual

Benning

Benning IT 115 User manual

Benning

Benning PV 1-1 Manual

Benning

Benning DUSPOL analog User manual

Benning

Benning TRITEST easy User manual

Benning

Benning IT 115 User manual

Popular Test Equipment manuals by other brands

ATEQ

ATEQ Hydra Owner's/operator's manual

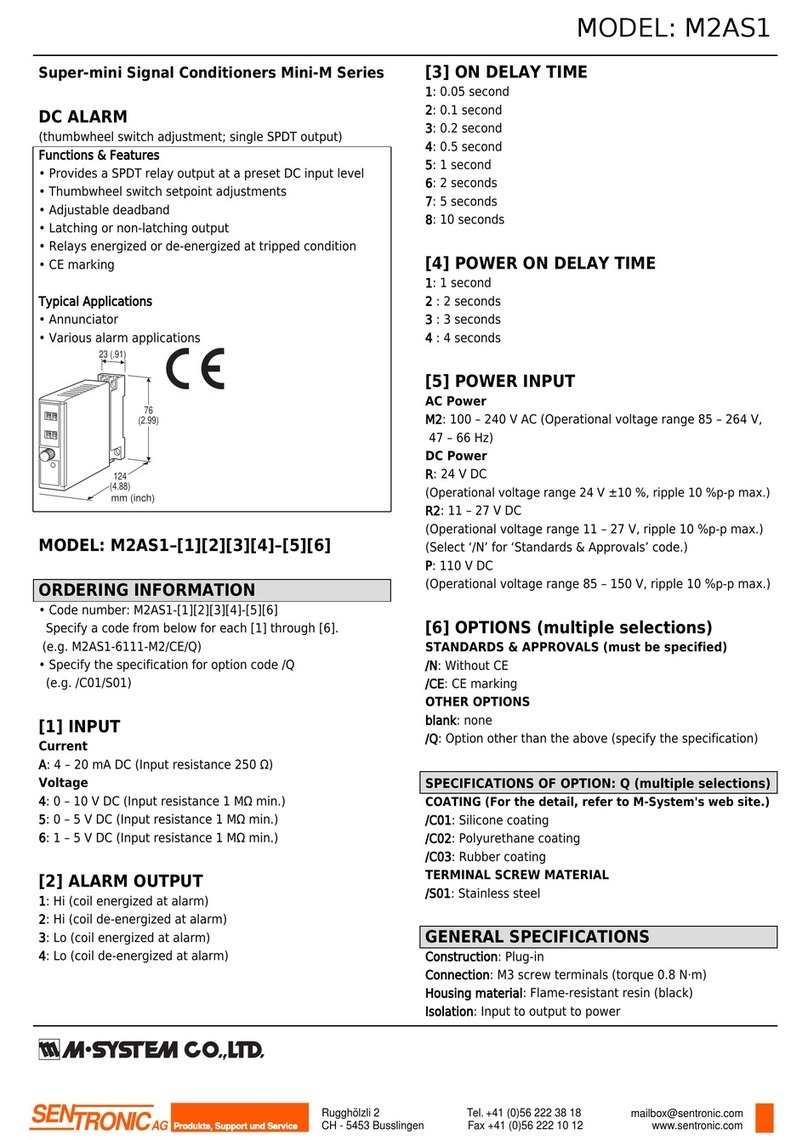

SENTRONIC

SENTRONIC M-SYSTEM Mini-M Series quick start guide

Agilent Technologies

Agilent Technologies Medalist x6000 installation guide

Rohde & Schwarz

Rohde & Schwarz Hameg IEEE-488 GBiP Interface HO740 FITTING INSTRUCTION

SenTech

SenTech iSOBER 10 user manual

sauter

sauter TVL-XL installation manual