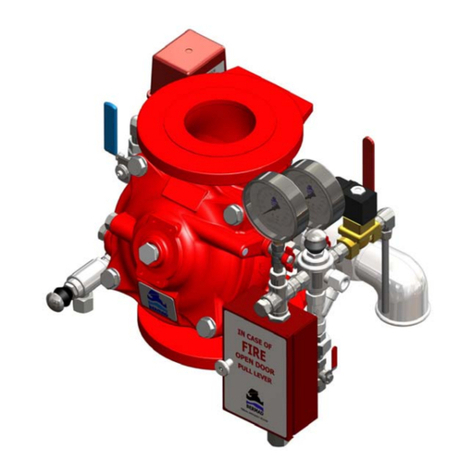

Model: FP 405-02 400 Series

BERMAD Fire Protection

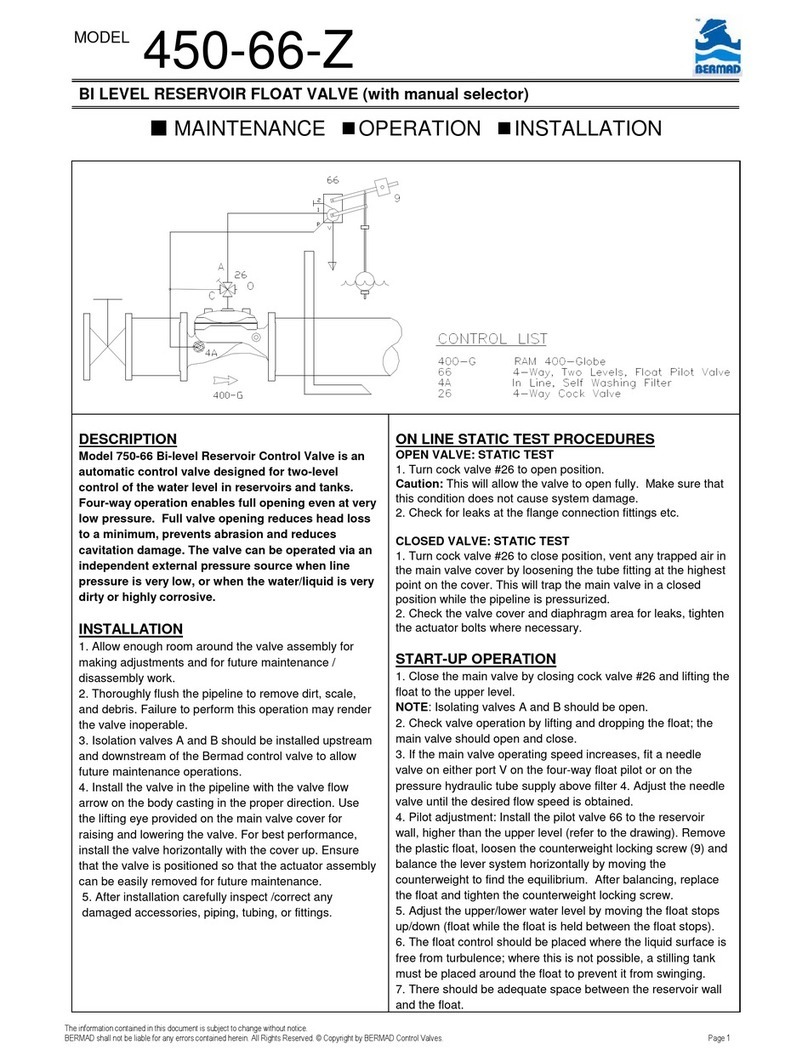

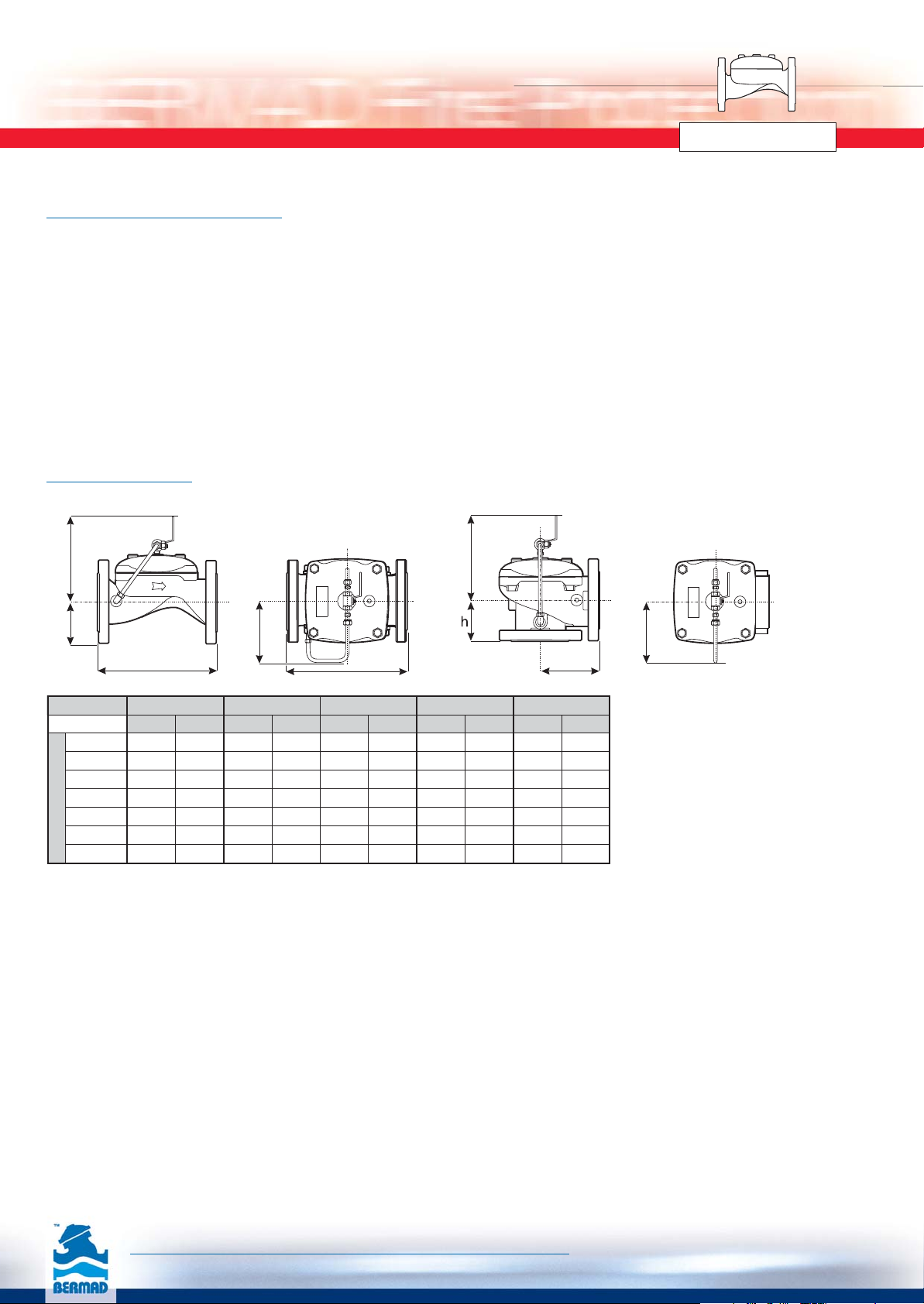

Th

R

Th

Tw

La1, La2

Tw

L1, L2, L1

Manufacturers Standard Materials

Main valve body and cover

• Cast Iron ASTM A126 class B(1)

Valve wetted parts

• Stainless Steel and Natural Rubber

Control System

• Brass with Copper tubing

Elastomers

• Nylon fabric reinforced polyisoprene

Coating

• Electrostatic Powder Coating Polyester,

Red (RAL 3002)

Optional Materials

Main valve body and accessories

• Carbon Steel ASTM A216-WCB(1)

• Stainless Steel 316

• Ni-Al-Bronze ASTM B-148

Control System

• Stainless Steel 316

Elastomers

• NBR

• EPDM

Coating

• High Built Epoxy Fusion-Bonded

with UV Protection, Anti-Corrosion

Technical Data

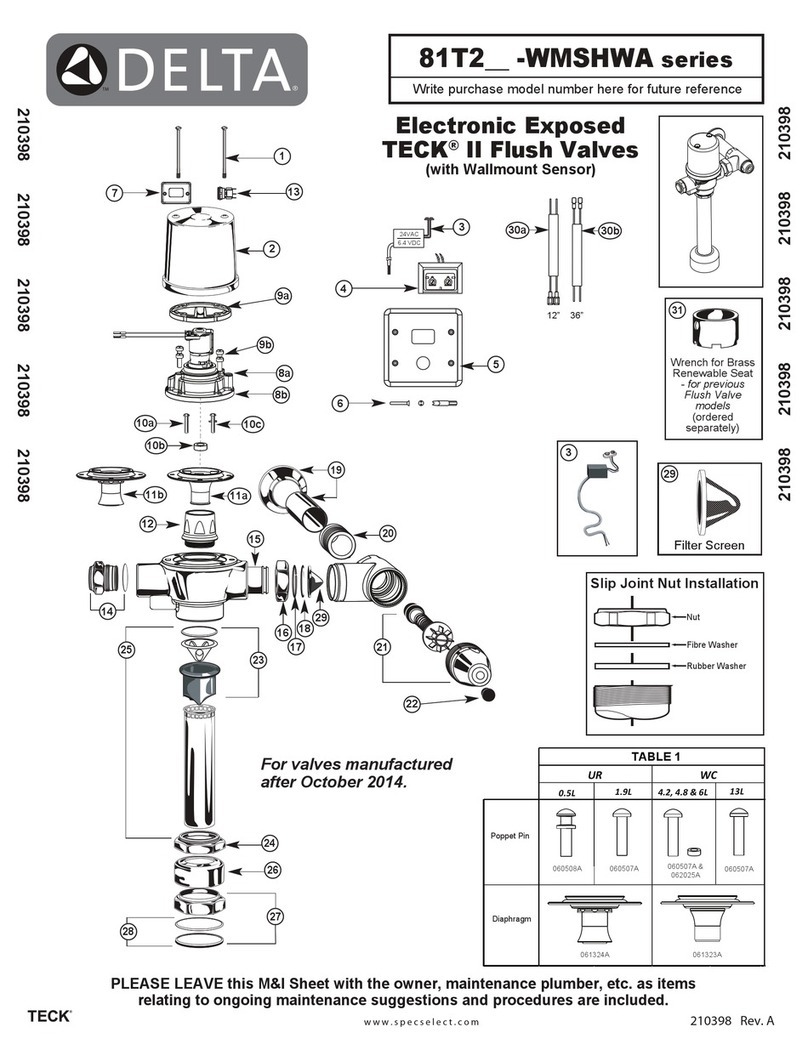

Valve Size 2” 21/2”3”4”6”

mm inch mm inch mm inch mm inch mm inch

(1)L1 205 81/2205 81/2250 913/16 320 129/16 415 165/16

(2)L2 180 71/16 210 81/4255 101/16 N/A N/A N/A N/A

(1)La1 121 33/4N/A N/A 153 6 160 65/16 N/A N/A

(2)La2 284 113/16 N/A N/A 300 113/16 313 125/16 341 137/16

Tw 284 113/16 284 113/16 300 113/16 313 125/16 341 137/16

Th 210 81/4210 81/4215 87/16 243 99/16 315 123/8

h83 31/4N/A N/A 101 4 112 47/16 N/A N/A

Dimensions

Available Sizes

• Globe: 11/2, 2, 21/2, 3, 4, 6, 8, 10 & 12"

• Angle: 2, 3 & 4"

Pressure Rating

• Max. working pressure: 235 psi (16 bar)

Connection Standard

• Flanged: ANSI B16.42 (Ductile Iron),

B16.5 (Steel & Stainless Steel ),

B16.24 (Bronze), B16.1 (Cast Iron), ISO PN16

• Threaded: NPT or BSP for 2 & 3"

Water Temperature

• 0.5 – 50°C (33 – 122°F)

Engineer Specifications

■The valve shall be a line pressure driven, elastomeric type globe valve with a rolling-diaphragm.

■Valve actuation shall be accomplished by a fully peripherally supported, one-piece balanced rolling-diaphragm,

vulcanized with a rugged radial seal disk. The diaphragm assembly shall be the only moving part.

■The valve shall have an unobstructed flow path, with no stem guide or supporting ribs.

■The valve cover shall be removable for in-line service, enabling all necessary inspection and servicing.

■The manual release pilot valve shall be supplied as an assembly with the main valve. It shall require only 1/4turn for

full opening or closing. It shall be equipped with a device to regulate the opening speed.

■The valve trim shall be supplied as an assembly, pre-assembled and hydraulically tested at an ISO 9000 & 9001

certified factory.

Notes:

1. L1 & La1 are for flanged ANSI

#125 / #150 and ISO PN16.

2. L2 & La2 are for threaded female,

NPT or BSP.

3. Data is for maximum envelope

dimensions, component

positioning may vary.

4. Provide adequate space around

valve for maintenance.

The information herein is subject to change without notice. BERMAD shall not be held liable for

any errors. All rights reserved. © Copyright by BERMAD. PE4PE-502 04

FP405-2 5/18/08 2:45 PM Page 2