Updated Jan 2020 Page #6

Unpacking and post shipment inspection

Make sure that until the actual installation the valve remains dry and clean in its original package.

Unpack the valve and make sure that all the wrapping materials are removed.

Before installation it is necessary to inspect that no damage to the valve occurred during

shipment; do not install a damaged valve!

Verify that the valve to be installed meets the design specifications of the specific installation site;

take extra care in making sure that the expected systempressure complies with the pressure rating

of the valve.

Site Preparation

Air Valves located above ground should be protected from freezing, contamination and

vandalism.

If the valve is to be installed in a pit, make sure that the pit has proper drainage and sufficient

dimensions for servicing the valve.

Flush the pipeline prior to the Air Valve installation in order to prevent damage to the valve

internals due to large debris carried by the water during startup

The C30 / C31 air valves are not to be used in systems containing high suspended solids;

consider selecting other BERMAD Air Valve models for such water type.

Installation

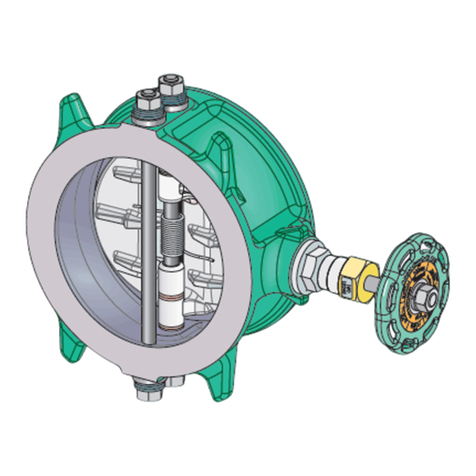

Typical Applications

Main Irrigation Networks –Air relief, protection against air accumulation and vacuum formation

downstream of pumps, along supply lines and at elevations in main irrigation networks.

Irrigation Control Heads –Air relief, protection against air accumulation and vacuum formation

at filtration and fertilization stations and downstream of main control valves.

Infield Systems –Protection against air accumulation and vacuum formation in proximity to water

meters and automatic regulators.

Landscape Irrigation –Protection against air accumulation and vacuum formation.

Please note:

1. If required a Down Outlet and a Connection to a Drainage Pipe can be fitted to the 2" / DN50

valve’s outlet.

2. Depending on the specific installation requirements a Surge Protection (SP) or an Inflow

Prevention (IP) device may be added to the air valve.