BERMAD FP 430-UF Owner's manual

The information contained in this document is subject to change without notice. BERMAD shall not be liable for any errors contained herein.

All Rights Reserved. © Copyright by BERMAD Control Valves.

IOM

Model: FP 430- Sizes: 2"-6"

PI4PE09-430-UF

Bermad Pressure Relief Valve

Model: 430-UF

NSTALLATIONI

PERATIONO

AINTENANCEM

Application Engineering

BERMAD

The information contained in this document is subject to change without notice. BERMAD shall not be liable for any errors contained herein.

All Rights Reserved. © Copyright by BERMAD Control Valves.

IOM

Model: FP 430- Sizes: 2"-6"

PI4PE09-430-UF

1. Safety First

BERMAD believes that the safety of personnel working with and around our equipment is the most important

consideration. Please read all safety information below and from any other relevant source before attempting to

perform any maintenance function.

Comply with all approved and established precautions for working with your type of equipment and/or environment.

Authorized personnel should perform all maintenance tasks.

Prior to performing a procedure, read it through to the end and understand it. If anything is not clear, ask the

appropriate authority.

When performing a procedure, follow the steps in succession without omission”

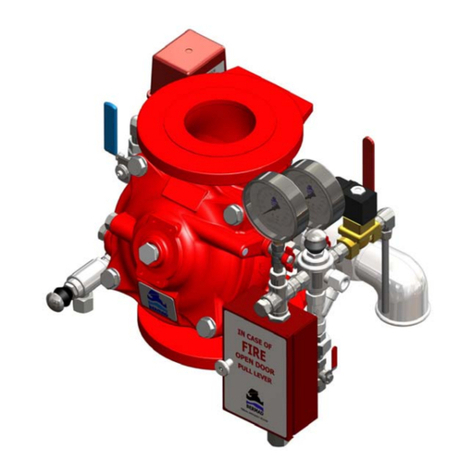

2. Description

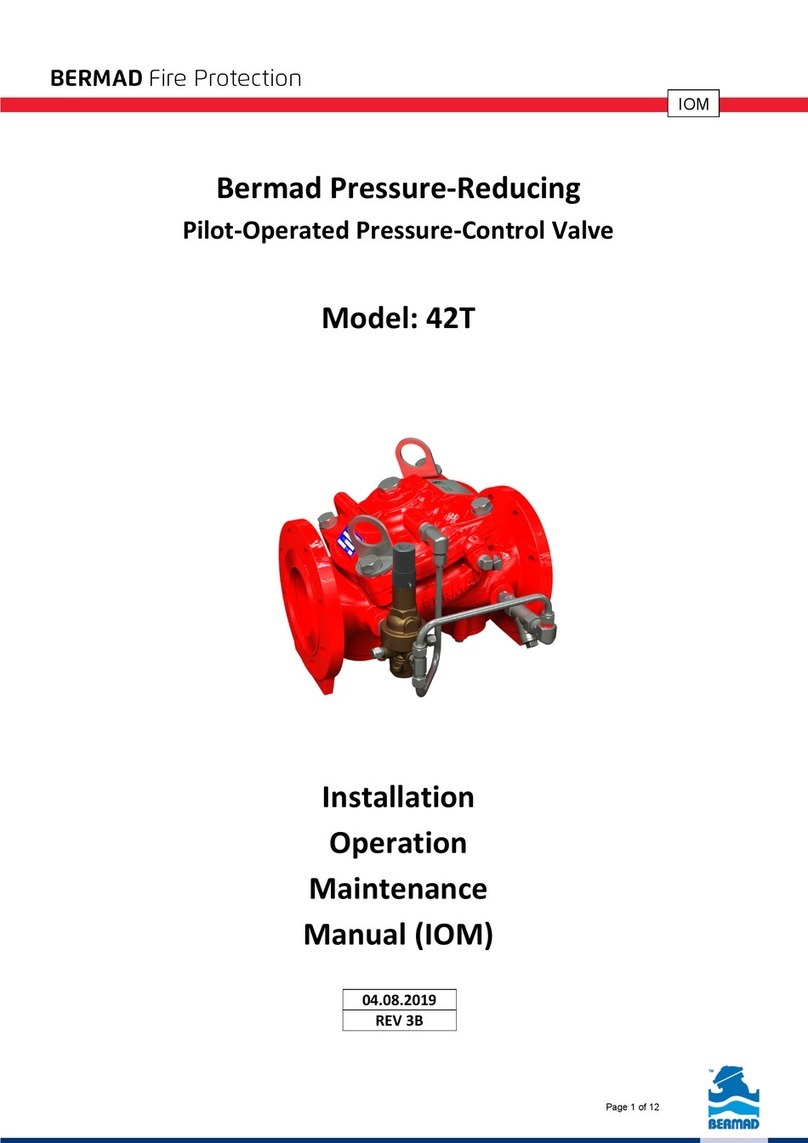

BERMAD’s Model FP 430-UF Pressure-Relief Valve is a pilot-operated, diaphragm type, high performance valve. It

accurately maintains a constant preset system pressure regardless of changing demands.

The Model FP 430-UF Pressure-Relief Valve reliably relives excess system pressure to sump or atmosphere, meeting all

NFPA, UL and FM requirements for fire pump service.

The actuator design enables quick and smooth valve action. According to the inlet pressure, the pilot valve regulates the

main valve throttling. This valve requires only existing line pressure to operate.

2.1 Models and Sizes

Models and Sizes covered by this document include the BERMAD Pressure-Relief Valve FP 430-UF, sizes 2”, 2.5”, 3”,

4”, and 6”. It is available in either the Globe.

Sizing shall be not less than according to NFPA 20 Table 2-20..

2.2 Operating Pressure Rating

All sizes are rated to maximum set pressure of 175 psi (12 bar).

2.3 Optional Features

Valve Position-Flow Indicator

This option provides the means for detecting motion of water through the valve according to requirements of NFPA 20.

This item is field retro-fit able.

Large Control Filter

This option provides extra capacity means for filtering of the water supplied to the control loop to achieve the essential

level of debris free water. This feature is recommended for those cases where there is any doubt as to the level of

particulate matter in the water.

3. UL Listed

BERMAD 430 UF Deluge Valve is UL Listed when installed with specific components & accessories. Refer to the

current UL Directory. Consult the manufacturer for any component approval recently to appear in the UL fire

protection equipment directory.

The information contained in this document is subject to change without notice. BERMAD shall not be liable for any errors contained herein.

All Rights Reserved. © Copyright by BERMAD Control Valves.

IOM

Model: FP 430- Sizes: 2"-6"

PI4PE09-430-UF

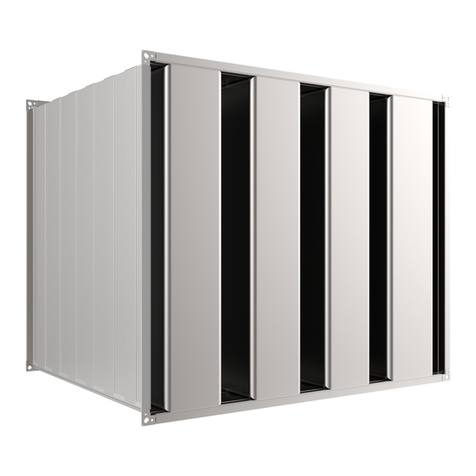

4. Installation

4.1 Before the valve is installed, flush the pipeline to remove any dirt, scale, debris, etc. Not flushing the line might

result in the valve being inoperable.

4.2 In cases where the valve is used for individual pump pressure-relief, locate the relief valve between the pump

and the pump discharge check valve. It shall be attached in a way that it can be readily removed for repairs

without disturbing the piping.

4.3 Allow enough room around the valve assembly for any adjustments and future maintenance/disassembly work.

4.4 Install the valve in the pipeline with the valve flow arrow on the body casting in the proper direction. Use the

lifting eye provided on the main valve cover for lifting and lowering the valve.

4.5 For best performance, install the valve horizontally with the cover up. However, other positions are acceptable.

Ensure that the valve is positioned so that the actuator can be easily removed for future maintenance.

4.6 After installation, carefully inspect/correct any damaged accessories, piping, tubing, or fittings. Ensure that there

are no leaks.

Figure 1: Installation Drawing

The information contained in this document is subject to change without notice. BERMAD shall not be liable for any errors contained herein.

All Rights Reserved. © Copyright by BERMAD Control Valves.

IOM

Model: FP 430- Sizes: 2"-6"

PI4PE09-430-UF

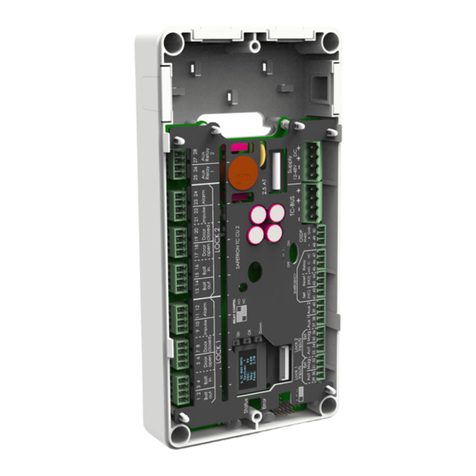

5. Operation

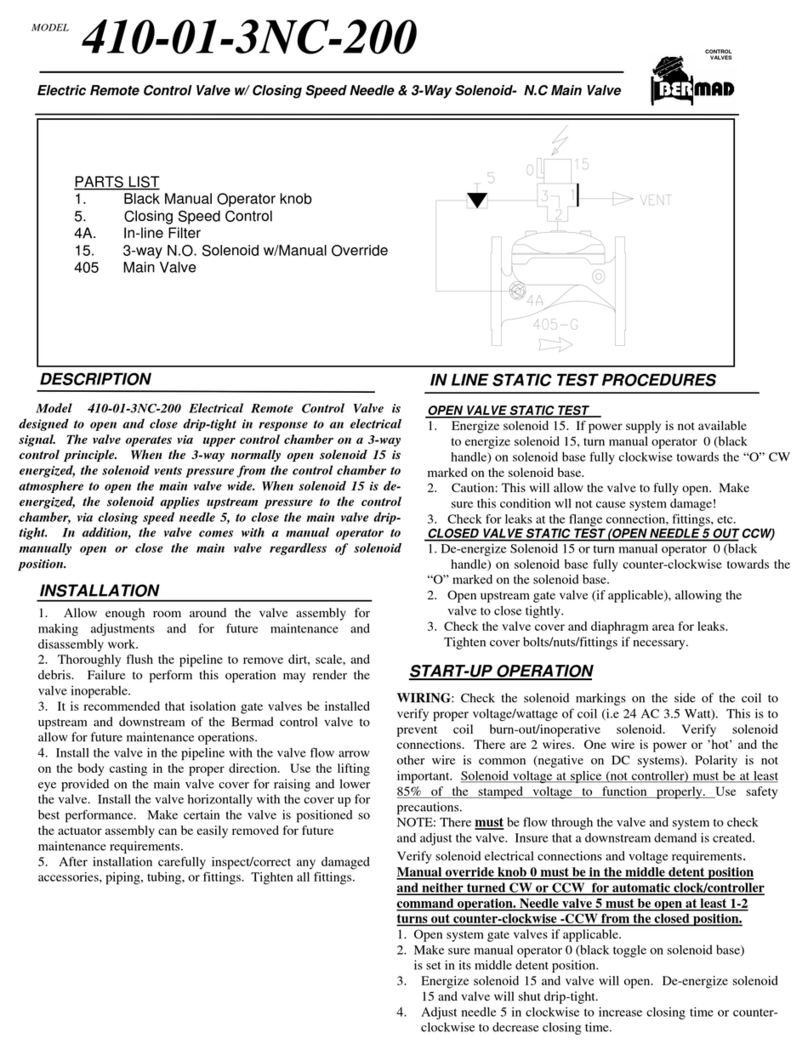

The Pressure-Relief Pilot Valve (3) senses inlet pressure and modulates the upper control chamber causing the main

valve to throttle, thus sustaining constant inlet pressure. When the inlet pressure raises above the pilot setting, the pilot

opens, pressure in the upper control-chamber decreases, and the main valve modulates open to relieve inlet pressure

and sustain pilot setting.

The pressure-relief pilot is equipped with an adjusting screw (5) to preset the desired inlet pressure and an internal

adjustable Needle Valve (2) to control the main valve closing speed.

.

Starting –up

5.1 Provide pump shut-off pressure to the Model FP 430UF Control Valve (1) inlet, allow no system

demand.

5.2 Create sufficient pressure (higher than the valve set pressure) to allow flow through the relief valve.

5.3 While relief valve is operating, wait for the valve inlet pressure to stabilize.

The pressure on the inlet side of the relief valve should be according to the factory pre-set adjusted

pressure.

5.4 Slowly allow system flow so that system pressure falls below the relief-valve adjusted pressure.

The relief-valve should slowly shut to drip-tight.

Readjusting

Tools required:

•Flat head screwdriver

•Adjustable wrench (6-10 inch)

The pilot valve is factory pre-set. The pre-set is clearly indicated on the pilot valve data-plate.

If readjustment to either the pressure or valve response is required, follow the following steps.

5.5 Ensure that there is nominal flow through the relief-valve.

5.6 Release the tension between the adjusting screw on the pressure-relief pilot valve and the fastening

nut by turning the fastening nut counterclockwise.

5.7 By alternately turning the adjusting screw (5) on the pilot valve (3) a half turn and then reading the

outlet pressure, gradually adjust the pressure:

5.8 Counterclockwise to decrease (—) the inlet pressure

or

5.9 Clockwise to increase (+) the inlet pressure.

Note: Valve response adjustment affects pre-set pressure. Any adjustment to valve

response requires rechecking pre-set pressure. See section 5.1, steps 1-4.

5.10 Repeat the Starting-up procedure, section 0 steps 1-4.

5.11 By turning the needle valve screw (2) on the pilot valve bottom, adjust the valve response. Turn:

5.12 Clockwise (while facing the screw) to decrease (-) the closing speed of the main valve

or

5.13 Counterclockwise to increase (+) the closing speed of the main valve.

5.14 Repeat the Starting-up procedure, steps 1-4.

The information contained in this document is subject to change without notice. BERMAD shall not be liable for any errors contained herein.

All Rights Reserved. © Copyright by BERMAD Control Valves.

IOM

Model: FP 430- Sizes: 2"-6"

PI4PE09-430-UF

6. Figure 2: Operation Drawing

7. Maintenance and Inspection Test

Warning: Do not turn off the water supply, to make repairs, without notifying local

security guards.

7.1 In any of the following inspections or testing procedures, if an abnormal

condition exists, see Troubleshooting for possible cause and corrective action.

7.2 The Model FP 430UF valve is to be inspected, tested and maintained in

accordance with the Maintenance Instructions of the plant, this Maintenance

Manual, as well as the Standard for the Inspection, Testing and Maintenance of

Water-Based Fire Protection Systems, NFPA 25.

8. Weekly Inspection

8.1 The system should be inspected under flow conditions.

8.2 Check that the main valve, pilot system, accessories, tubing & fittings, are all in good condition, damage free

and not leaking.

8.3 The fastening nut, of the pilot valve (4 figure 2) adjusting screw, should be fastened tightly.

8.4 For circulation type installations, verify that sufficient water flows through the valve when fire pump is operating

at shut-off pressure (churn) to prevent the pump from overheating.

8.5 Verify that the pressure upstream of the relief valve fittings in the fire pump discharge piping does not exceed

the pressure for which the system components are rated.

The information contained in this document is subject to change without notice. BERMAD shall not be liable for any errors contained herein.

All Rights Reserved. © Copyright by BERMAD Control Valves.

IOM

Model: FP 430- Sizes: 2"-6"

PI4PE09-430-UF

9. Monthly Inspection and Test

9.1 Complete Weekly Inspection.

9.2 During the monthly fire pump flow test, it shall be verified that the pressure relief valve is correctly adjusted and

set to relieve at the appropriate pressure and closes below the pressure setting

Abnormal Conditions - Troubleshooting

SYMPTOM PROBABLE CAUSE REMEDY

Filter screen (4) blocked. Remove filter cap and

screen to clean. Filter might

be insufficient. See Note

below.

Pulsates or hunts. Slowly adjust needle

valve (21) until pulsation

stops.

Needle valve (21) not

properly adjusted.

Factory set at ½ or 1½

open. Adjust.

Valve fails to regulate

Air trapped in main valve

cover.

Loosen cover tube fitting

at the highest point, allow

the air to escape and re-

tighten.

Insufficient inlet pressure. Check/create inlet

pressure.

Valve fails to open

Pilot is adjusted to high. Turn adjusting screw

CCW on

pilot (5).

Filter screen (4) blocked. Remove filter cap and

screen to clean. Filter might

be insufficient. See Note

below.

Debris trapped in main

valve.

Remove and inspect

actuator assembly.

Check seat.

Check for foreign bodies.

Rinse at high flow-rate.

Diaphragm in main valve

is leaking.

Valve fails to seal inlet

pressure

Diaphragm in pilot valve

is leaking.

Open the valve cover,

inspect diaphragm.

If damaged, replace.

Note: Mark “F” – Large Filter

In cases where the filter screen frequently becomes blocked, install a filter with filtration capacity of at least 80 mesh, 250 µ m.

10. Difficulty in Performance

Where difficulty in performance is experienced, the manufacturer or his authorized representative should be contacted

if any field adjustment is to be made.

The information contained in this document is subject to change without notice. BERMAD shall not be liable for any errors contained herein.

All Rights Reserved. © Copyright by BERMAD Control Valves.

IOM

Model: FP 430- Sizes: 2"-8"

PAGE 7 OF

The information contained in this document is subject to change without notice. BERMAD shall not be liable for any errors contained herein.

All Rights Reserved. © Copyright by BERMAD Control Valves.

IOM

Model: FP -430- UF Sizes: 2"-12"

PAGE 8 OF

The information contained in this document is subject to change without notice. BERMAD shall not be liable for any errors contained herein.

All Rights Reserved. © Copyright by BERMAD Control Valves.

IOM

Model: FP -430- UF Sizes: 2"-12"

PAGE 9 OF

Table of contents

Other BERMAD Control Unit manuals

BERMAD

BERMAD 430 User manual

BERMAD

BERMAD 700 Series User manual

BERMAD

BERMAD C10 User manual

BERMAD

BERMAD 400E-5D Owner's manual

BERMAD

BERMAD 450-60 User manual

BERMAD

BERMAD 410-01-3NC-200 User manual

BERMAD

BERMAD 435 User manual

BERMAD

BERMAD 400E-Y General instructions

BERMAD

BERMAD 720 User manual

BERMAD

BERMAD C15 User manual

BERMAD

BERMAD 430-Z-3W Owner's manual

BERMAD

BERMAD C30 User manual

BERMAD

BERMAD 400 Series User manual

BERMAD

BERMAD C80 Instruction manual

BERMAD

BERMAD 450-66-Z User manual

BERMAD

BERMAD 420 Guide

BERMAD

BERMAD K10 User manual

BERMAD

BERMAD 730-UF Owner's manual

BERMAD

BERMAD BC-73Q-P User manual

BERMAD

BERMAD BC-710-P User manual