File Name: IOM BC-710-P (1.5in

8in) Rev. 00 Prepared By: RC Date: 06/17

engineering@vbtech.com ●www.vbtech.com ●www.bermad.com

The information contained in this document is subject to change without notice. BERMAD shall not be liable for any errors

contained herein. All Rights Reserved. © Copyright BERMAD Control Valves.

Model BC-710-P IOM

Solenoid Controlled Valve

Description

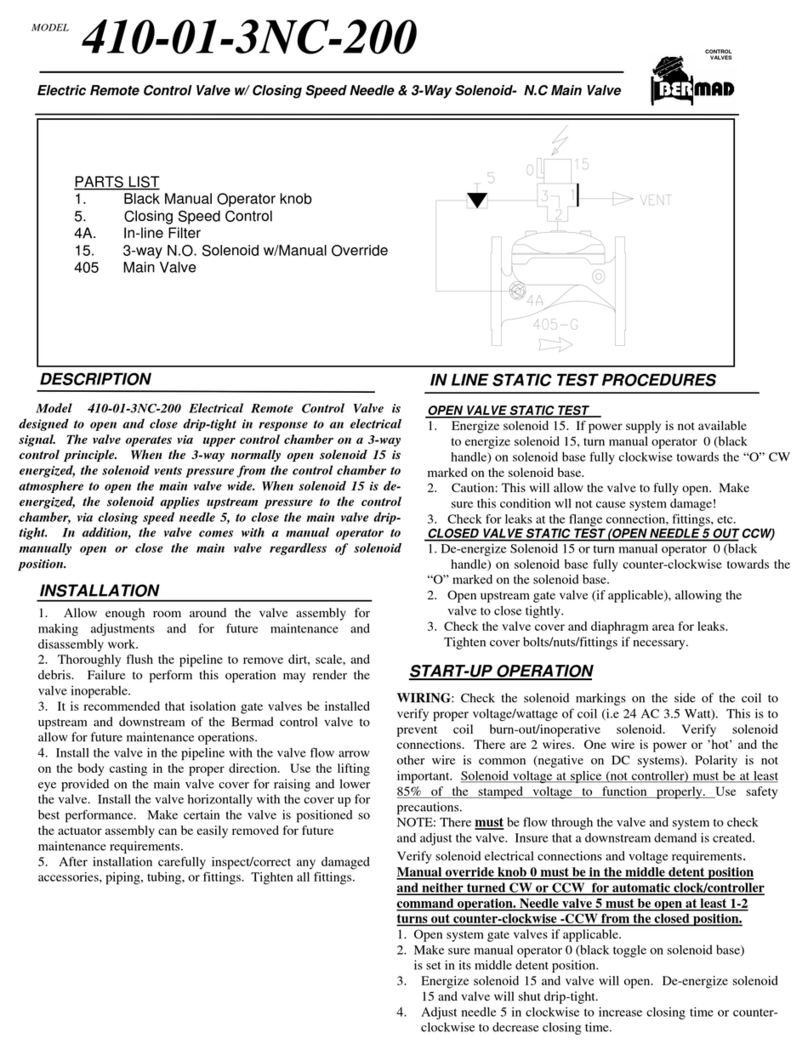

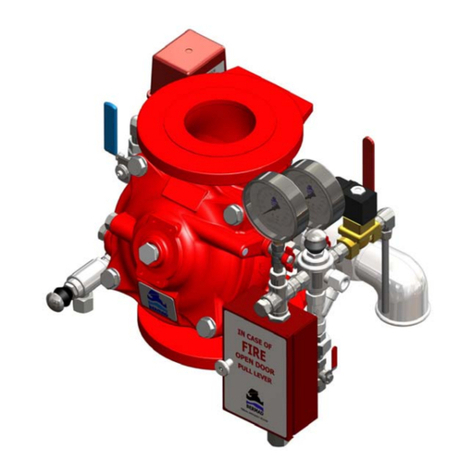

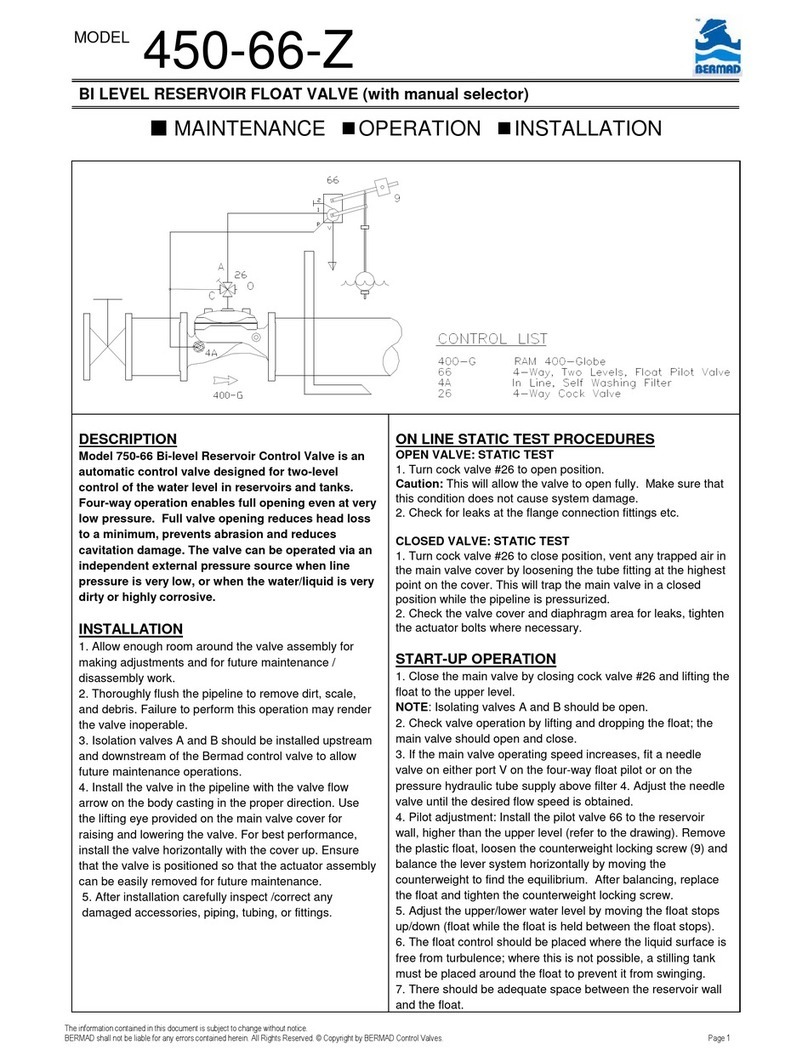

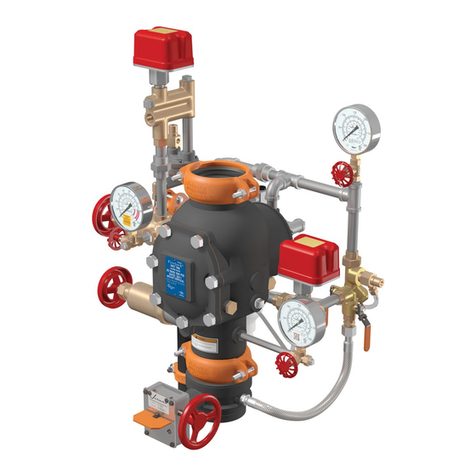

The Model BC-710-P Solenoid Controlled Valve opens and closes in response to an electrical signal. When solenoid 15 is signaled

to open the main valve, the solenoid vents the cover chamber to atmosphere. When solenoid 15 is signaled to close the main valve,

upstream pressure is applied to the cover chamber, closing the valve drip-tight.

Installation

1. Allow enough room around the valve assembly for making adjustments and for future maintenance and disassembly work.

2. Thoroughly flush the pipeline to remove dirt, scale, and debris. Failure to perform this operation may render the valve inoperable.

3. It is recommended that isolation valves be installed upstream and downstream of the Bermad pressure reducing system to allow for

future maintenance operations.

4. Install the valve in the pipeline with the valve flow arrow on the body casting in the proper direction. Install the valve horizontally with

the cover up for best performance. Make certain the valve is positioned so the cover assembly can be easily removed for future

maintenance requirements.

5. System power connections, control cabinet, controller, sensors & wiring should be carried out by authorized electrical engineer /

electrician and comply with all relevant electrical codes.

6. Check the solenoid specification and the markings on the side of the coil to verify proper voltage of coil (i.e. 120/60=120VAC). This

is to prevent coil/solenoid burn-out.

7. Connect the power cables to the solenoid. The solenoid has three connections, one which is either a green/yellow wire or marked

with the grounding symbol, this is an earth ground or conduit ground wire for safety precautions. The other two connections are

power/’hot’ and common, or negative on DC systems. These two connections have no polarity, so either wire can be used for

power/common. Do not apply power to the ground connection or it will burn the solenoid and/or coil. Note: There must be at least

85% of the voltage stamped on the side of the coil at the solenoid splice, not controller, for the solenoid to function properly.

8. If applicable, run the appropriate conduit and cables to wire a limit switch or position transmitter. See relevant accessories IOM for

more information.

9. After installation carefully inspect/correct any damaged accessories, piping, tubing, or fittings.

Commissioning & Calibration

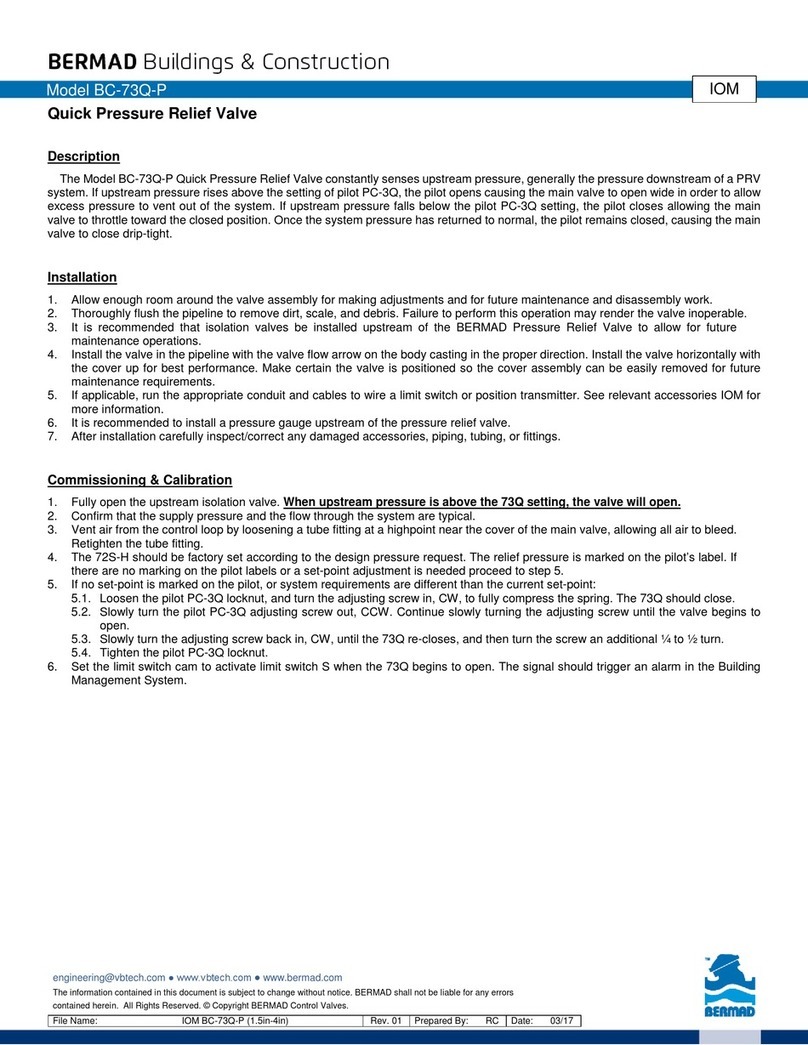

There must be sufficient flow through the valve and system to check and adjust the valve. Insure that a downstream demand is created.

Ball valve 1 must be open at all times for the valve to operate.

1. Fully open the upstream isolation valve and partially open the downstream isolation valve, to fill the consumer line downstream of

the valve, in a slow and controlled manner.

2. Confirm that the supply pressure and the flow through the system are typical. If necessary, create flow by opening a hydrant, or

reduce the flow/pressure by adjusting the downstream/upstream isolation valves.

3. If a limit switch is installed, set the limit switch cam to activate the limit switch when the 710 is in the fully closed position. The signal

should trigger an alarm in the Building Management System.

4. The Model BC-710-P has two common configurations:

4.1. Normally Closed Valve, with a Normally Open Solenoid. In this configuration, energizing the solenoid will vent the cover

chamber to atmosphere, causing the main valve to open.

4.2. Normally Open Valve, with a Normally Closed Solenoid. In this configuration, energizing the solenoid will apply line pressure to

the cover chamber, causing the main valve to close.

5. Cycle the valve open and closed to verify valve operation.

6. Fully open the upstream and downstream isolation valves, if they are not already.