Part No. 350245 Form No. F011003A

Page 6 of 12

OPERATION continue

16

OVERSEEDING OPERATION continued

MOW: Mow the lawn to it's normal cut height

DRY: Be sure grass is ry. Wet con itions can cause in-

crease amage to healty grass.

SET DEPTH: With engine off, set the raking epth so that the

bla es just touch on a flat surface (i.e. riveway, or si ewalk).

START ENGINE: See Page 5.

ENGAGE BLADES: Pull back on the bail on the operators

han le. NOTE: When engaging the blades in heavy load

conditions (i.e. heavy thatch, or very uneven turf), push down

on the operators handle lifting the front wheels slightly.

Engage the blades. Slowly lower the unit into the turf.

SLICE: Verti-cut a small test area an examine the results.

Some thatch an cut stems shoul be remove an eposite

on top of the healthy grass. Grass runners shoul be cut an

rea y for removal. If excessive amage occurs to healthy

grass, a just the bla e epth to ecrease amage. Continue

raking the yar , working in one irection (i.e. north-south, or

east-west). NOTE: If a large drop in engine RP occurs, or

the unit pulls you forward and bounces during operation the

blade depth is set too low.

REMOVE THATCH/STEMS: After verti-cutting, a layer of

thatch an cut stems will be eposite over the top of the lawn.

We suggest the use of a lawn vacuum or wheele blower for

collection an removal of the thatch/stems.

DO NOT- Use this machine on any surface other than a lawn.

DO NOT- Use this machine on slopes in excess of 19°.

DO NOT- Allow persons unfamiliar with this equipment to

operate it.

DO NOT- Allow chil ren to operate this equipment.

RAKING/SLICING TIPS

THATCH: Thatch is a ense layer of ea grass, clippings,

an roots that buil s up over time at the base of of the lawn

preventing air, water, an fertilizer from reaching the soil.

This can cause shallow root evelopment an make a lawn

more susceptible to rought an isease. Thatch also

provi es an i eal environment for insects to hi e an

multiply. Perio ic removal of thatch will keep your lawn in

goo health.

HEAVY THATCH: Lawns with an excessive amount of thatch

will require multiple treatments for effective removal. Trying

to remove excessive thatch (greater than 3/4"[19 mm] eep)

in one treatment will amage or estroy the living part of the

lawn. It is best to remove heavy thatch in seasonal treat-

ments (i.e. spring, an fall).

CHECK: Before begining, it is best to evaluate the con i-

tion of the lawn by cutting one or more core samples from

area to be treate . A core can be cut using a piece of pvc,

or metal pipe. Hammer the pipe into the groun , remove it,

push the core out of the pipe an inspect it to etermine the

epth of thatch in your yar .

SLOPES: Rake slopes across not up an own. This is

much easier an safer for the operator an is better for the

lawn. Raking across will help to re uce runoff uring

watering an allow the slope groun to hol more see ,

fertilizer, an water. The units maximum operating slope is

35% or 19°.

DEPTH: The wi e range of epth a jusment on your unit is

provi e to allow for bla e wear. Setting the reel eeper will

not pro uce better, or quicker results. The flail reel is

inten e to be set so it just touches the surface on flat

groun . The slicing reel shoul be set even with the groun

for verti-slicing work, an set to a maximum 1/2" epth for

oversee ing jobs. Setting the reel eeper than this will only

result in premature wear on the unit (i.e. faile belt). If you

esire to work the groun eeper than the above gui lines

allow, it shoul be one gra ually in multiple passes.

Hints!

OVERSEEDING OPERATION

MOW: Mow the lawn to it's normal cut height

DRY: Be sure grass is ry. Wet con itions can cause in-

crease amage to healthy grass.

SEED: Spre grass see accor ing to the see suppliers

irections (e.g. 10 lbs. per 1000 ft2 [4.5 kg. per 93 m2 ])

SET DEPTH: With engine off, set the raking epth so that the

bla es reach 1/4"-1/2"(6-12 mm) below a flat surface (i.e.

riveway, or si ewalk).

START ENGINE: See Page 5.

ENGAGE CLUTCH: Pull back on the bail on the operators

han le. NOTE: When engaging the clutch in heavy load

conditions (i.e. heavy thatch, or very uneven turf), push down

on the operators handle lifting the front wheels slightly.

Engage the clutch. Slowly lower the unit into the turf.

DO NOT- Use this machine on any surface other than a lawn.

DO NOT- Use this machine on slopes in excess of 19°.

DO NOT- Allow persons unfamiliar with this equipment to

operate it.

DO NOT- Allow chil ren to operate this equipment.

SLICE: Run machine over the area that has been see e to

incorporate the see into the soil. If excessive amage

occurs to healthy grass, a just the bla e epth to ecrease

amage. Continue raking the yar , working in one irection

(i.e. north-south, or east-west). NOTE: If a large drop in

engine RP occurs, or the unit pulls you forward and

bounces during operation the blade depth is set too low.

WATER/FERTILIZE: After the see has been worke into

the soil, water an fertilize accor ing to the see suppliers

irections.

VERTI-CUTTING OPERATION

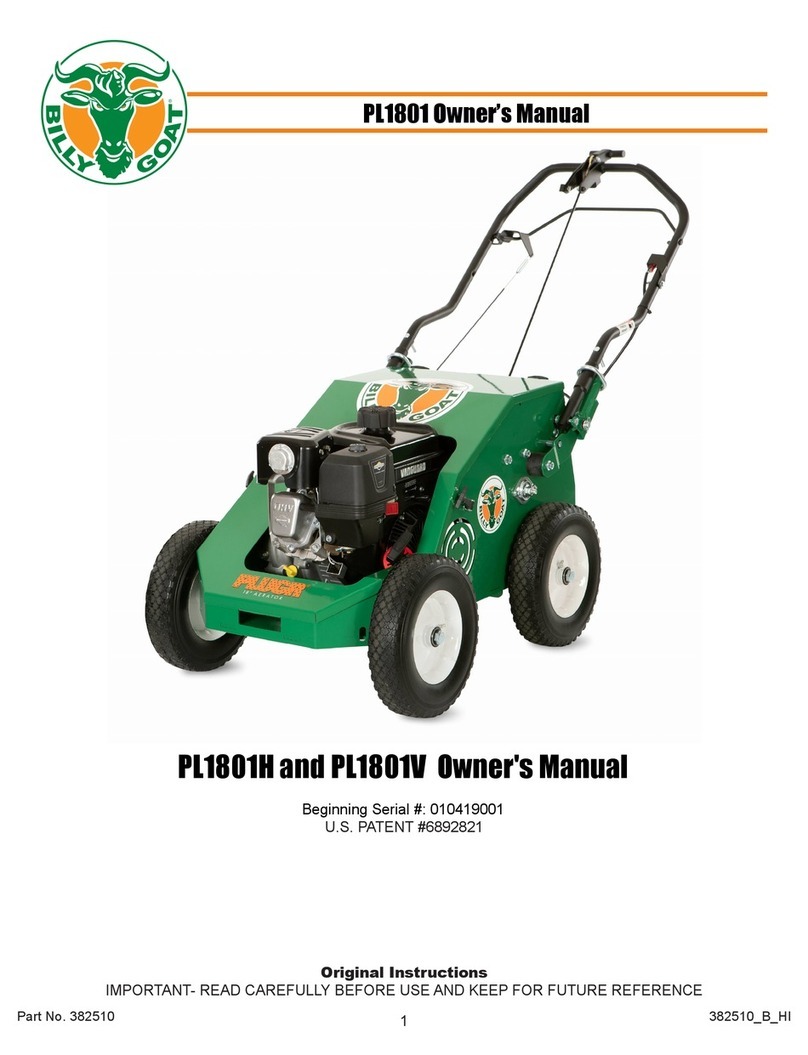

This unit is equippe with a fol ing upper han le for easier storage

an transportation. The han le can be fol e by sli ing the han le

lock loops(item 28) up. This releases the upper han le, allowing it to

be fol e over the unit.

FOLDING HANDLE

This unit requires two people to lift it. With the han le in the fol e

position, lift hol ing the lower han le an belt/shaft guar one on

each si e of the machine. Secure the machine in place uring

transport.

HANDLING & TRANSPORTING