Content

Preface.................................................................................................................................................... 1

Content................................................................................................................................................... 2

1. Unpacking, Installation and Debugging.............................................................................................4

1.1 Unpacking................................................................................................................................. 4

1.2 Accessories Checking................................................................................................................6

1.3 Installation Conditions and Operating Environment.................................................................8

1.4 Installation................................................................................................................................. 9

1.5 Inspection after Installation..................................................................................................... 13

2. User Instructions...............................................................................................................................14

2.1 Functions................................................................................................................................. 14

2.1.1 Product Concept............................................................................................................ 14

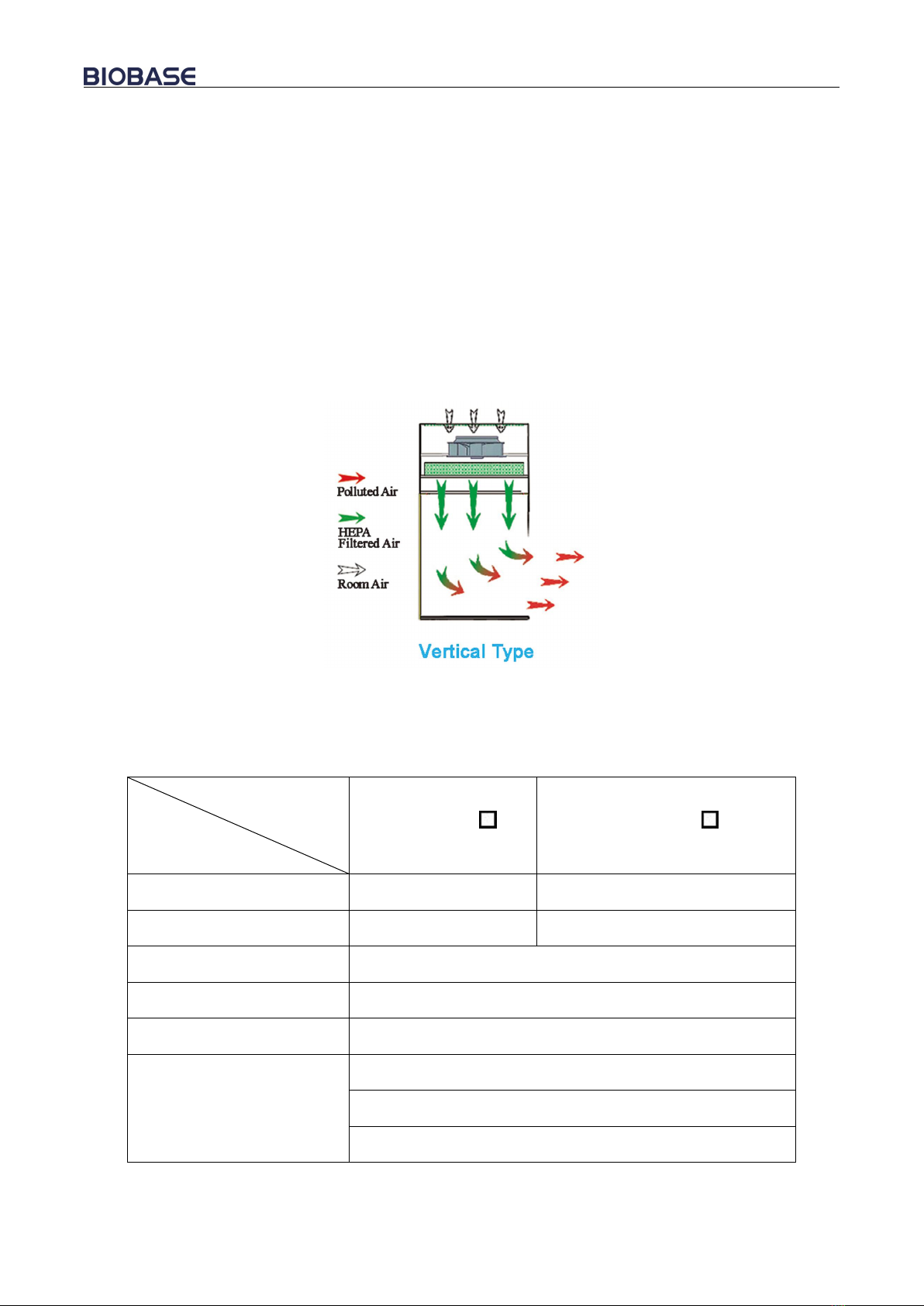

2.1.2 Operating Principle/Air flow Pattern (Picture 7).......................................................... 14

2.1.3 Protected Object............................................................................................................ 14

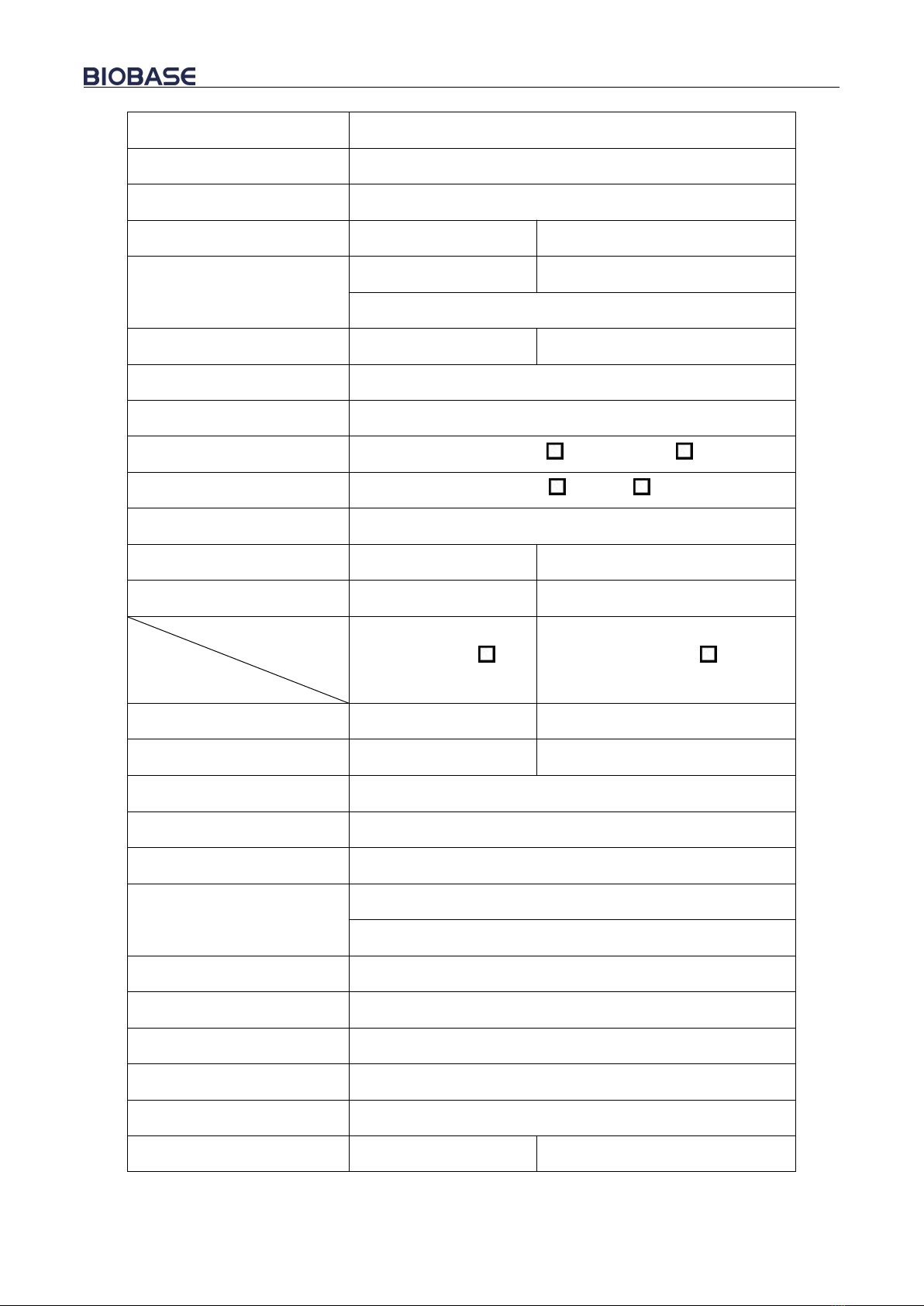

2.1.4Technical Parameters..................................................................................................... 14

1) Vibration Amplitude................................................................................................................. 16

2) Illumination...............................................................................................................................16

3) Electrical Characteristic............................................................................................................ 16

2.2 Product Structure.....................................................................................................................17

2.2.1 Structural Composition of BBS-DDC/BBS-SDC (Picture 8)....................................... 17

2.2.2 Structural composition of BBS-DSC/BBS-SSC (Picture 9)......................................... 18

2.2.3 Structure Introduction....................................................................................................18

2.3 Instructions for Operation....................................................................................................... 20

2.3.1 Normal Operation Notice.............................................................................................. 20

2.3.2 Operation Process..........................................................................................................20

2.4 Daily Maintenance.................................................................................................................. 21

2.4.1 Clean the operating area surface................................................................................... 21

2.4.2 Clean the external surface and front window................................................................21

2.4.3 Comprehensive maintenance period............................................................................. 21