The unit is designed for operation in cold rooms, incubators and closed laboratory

rooms at ambient temperature from +4°C to +40°C and maximum relative humidity

80% for temperatures up to 31°C decreasing linearly to 50% relative humidity at 40°C.

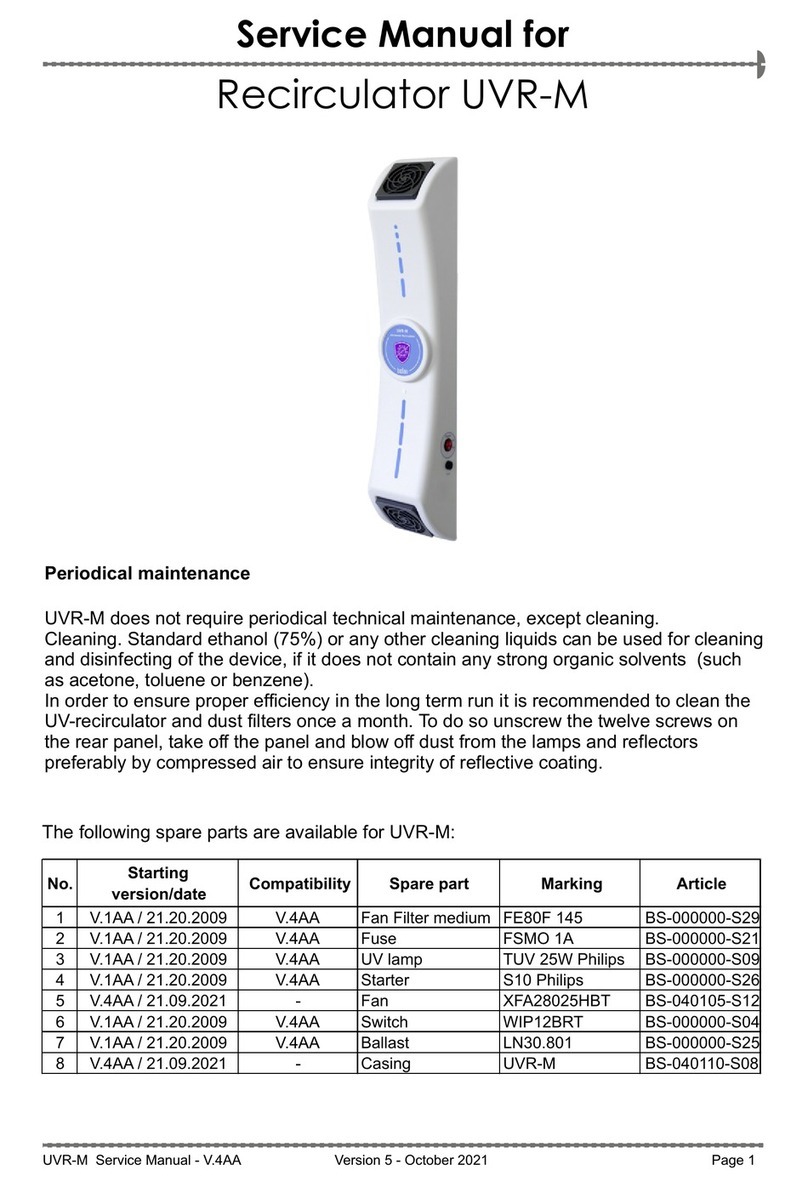

·Open UV-lamp.............................................TUV 25 W G13 UV-C Special Philips

·Radiation type ...............................................................UV (254 nm), ozone free

·UV-lamp life time ....................................................................................8000 hrs

·UV-recirculator ............................................TUV 25 W G13 UV-C Special Philips

·Digital time setting of direct UV-exposure .........................................1 min – 24 h

·Luminescent (Visible light) lamp.........................................15 W/830 G13 Philips

·

·

·

·

·

·Thickness of upper front panel ......................................................................8 mm

·Thickness of protective front screen .............................................................4 mm

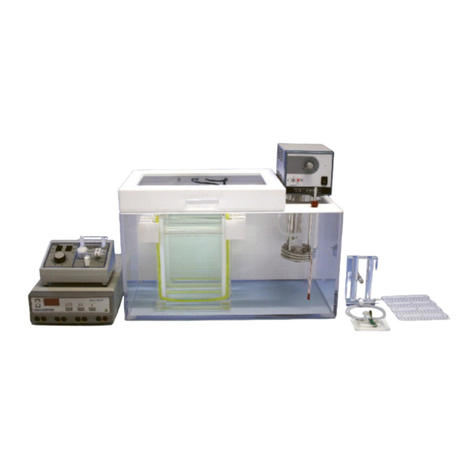

·Working place ....................................................................................650x475 mm

·Overall size ................................................................................ mm

·

·........................................................................................

·Weight*........................................................................................................31.2 kg

* Accurate within ±10%

Glass type ...........................................................................Euroglass, (Germany)

Side walls material type.....................................................................painted steel

Optical transmission ......................................................................................95 %

UV protection ................................................................................................96 %

Protection film type ..........................................................................4 MIL CLEAR

690x585x555

Power outlet inside the unit (exclude V.3AA)................................................1 piece

67 W

** Note! Consumed power of device connected via internal power socket should

not exceed 1000 W for 230V.

6. Technical Maintenance

Power consumption

Biosan is committed to a continuous programme of improvement, specifications may

be changed without notice.

11

DescriptionOptional accessories Catalogue number

moving table with a drawer and wheel

locks, dimensions 800x600x745 mm

T-4 BS-040101-BK

Operating voltage Power outlet

100–240 V, 50/60 Hz —

100–240 V, 50/60 Hz US**

100–240 V, 50/60 Hz UK**

Version number

V.3AA

V.3AE

V.3AB

100–240 V, 50/60 Hz Euro**V.3AD

Plug

Euro

US

UK

Euro

100–240 V, 50/60 Hz AU**V.3A04 Euro