English | 17

Bosch Power Tools 1 609 929 Y14 | (23.8.11)

Suitable spray materials and recommended diluting

agents

fWhen diluting, pay attention that the spray material

and the diluting agent correspond. When using a faulty

diluting agent, lumps can develop that can lead to clogging

of the spray gun.

The tool is not suitable for processing dispersion paint (wall

paint/latex).

Please also observe the practical advice/tips of the spray ma-

terial manufacturers.

Diluting Spray Material

For spray material that needs to be diluted, proceed as fol-

lows:

– Take the measuring cup 22.

– Stir the spray material thoroughly.

– Fill a sufficient quantity of spray material into the spray-

material container 8. (see “Filling in Spray Material”,

page 17)

– Dilute the spray material by 10 % with paint thinner. Ex-

amples:

– Stir the spray material thoroughly.

– Carry out a test-spray run on a test surface. (see “Spray-

ing”, page 17)

When the spraying pattern is perfect, start the spray job.

or

When the spraying result is not satisfactory or when no paint

comesout, pleasecontinue asdescribedunder“Correctionof

Malfunctions” on page 19.

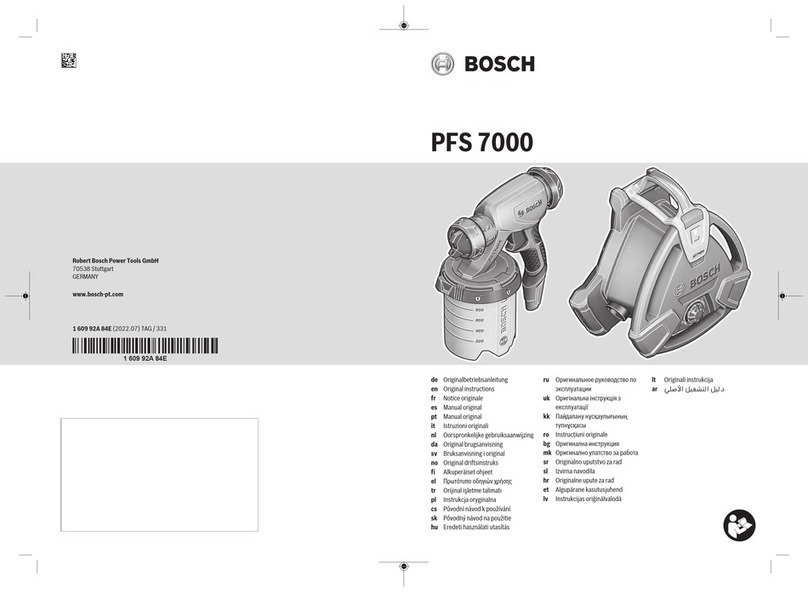

Filling in Spray Material (see figures C1–C2)

fBefore any work on the machine itself, pull the mains

plug.

– Unscrew the container 8from the spray gun.

– Turn the suction tube 10 so that the spray material can be

sprayed with almost no residue:

– Fillthespraymaterialinto the container and screw the con-

tainer firmly to the spray gun.

Starting Operation

fObserve correct mains voltage! The voltage of the pow-

er source must agree with the voltage specified on the

nameplate of the machine. Power tools marked with

230 V can also be operated with 220 V.

fDuring operation, the base unit must always stand hor-

izontally on a level surface. Never tilt the base unit or

set it upright when switched on.

fPay attention that the base unit cannot draw in dust or

other contamination during operation.

fMake sure never to spray on the base unit.

Switching On

– Always place the base unit horizontally on a level and clean

surface.

– Plug the mains plug into a socket outlet.

– Grasp the spray gun by the handle and point it at the spray

surface.

– For switching on, turn the control knob 16 on thebase unit

toward the right to the stop.

It is recommended to start with the maximum air

flow. (“Adjusting the Air Flow”, see page 18)

– Pull the trigger switch 9on the spray gun.

Note: When the base unit is switched on, air always flows out

at the nozzle 11.

Switching Off

– Release the trigger switch 9and turn the control knob 16

toward the left to the stop.

– Place down the spray gun in the set-down port 17.

– Pull the mains plug from the socket outlet.

Working Advice

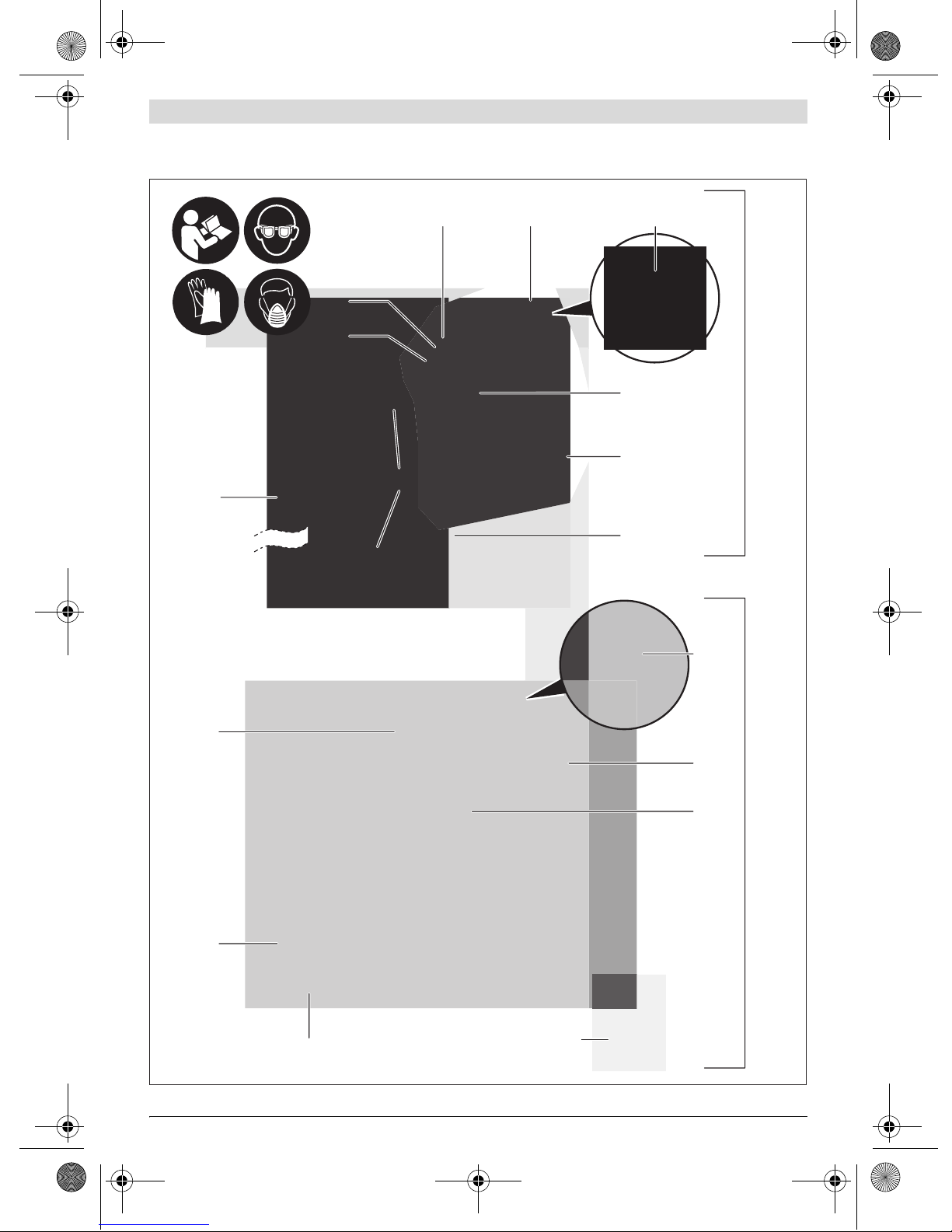

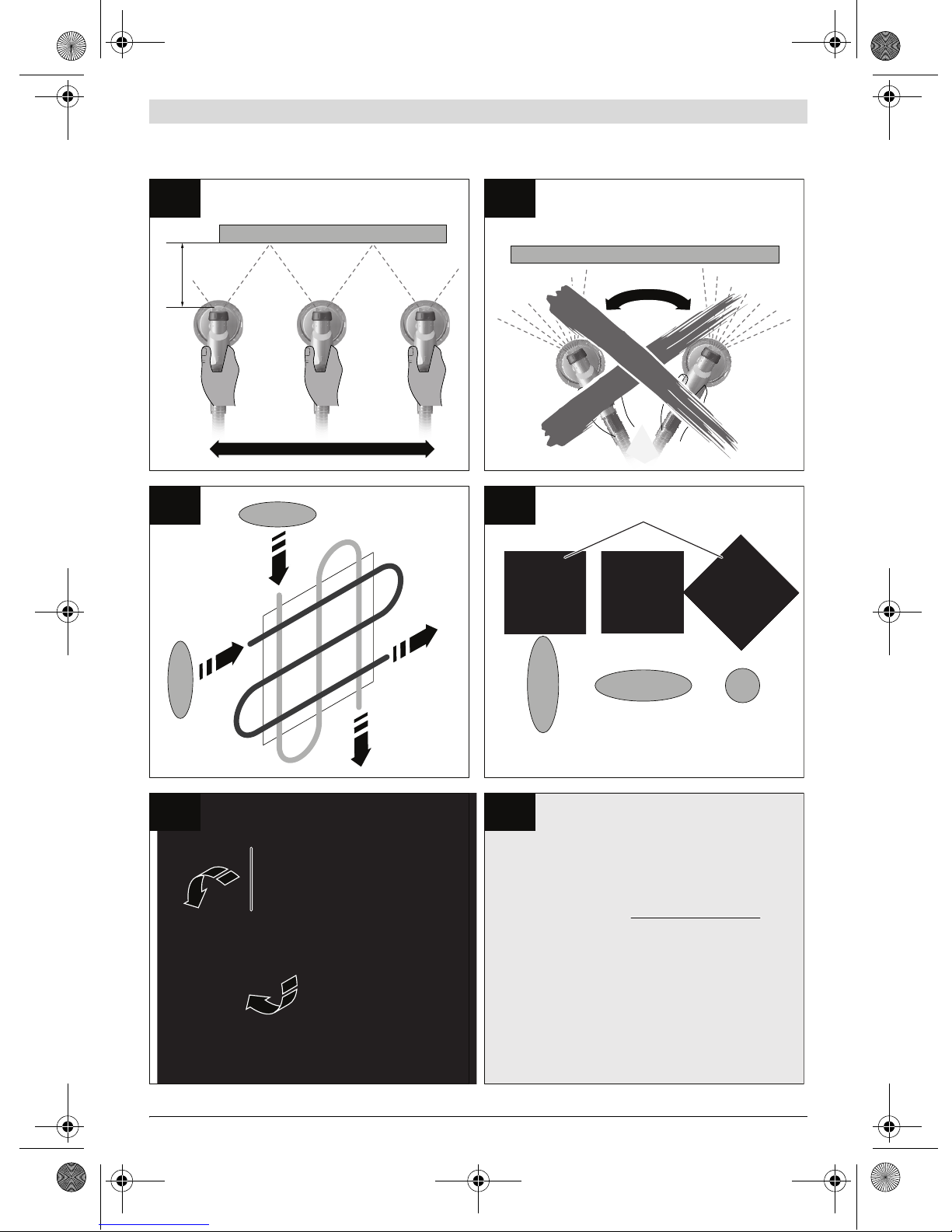

Spraying (see figures D–E)

Note: Observe the wind direction whenoperating the power

tool outdoors.

– Firstly, carry out a test-spray run and adjust the spray pat-

tern and the spray material quantityaccording to thespray

material. (For adjustments, see the following sections)

– Makesureto hold thespraygun vertical tothespray object

at a uniform clearance between 5 – 15 cm.

– Begin the spraying procedure outside the target area.

– Move the spray gun evenly cross-wise or up-and-down, de-

pending on the spray pattern setting.

Anevensurface qualityisachieved when the pathsoverlap

by4–5cm.

– Avoid interruptions within the spray surface.

Guiding the spray gun evenly will provide uniform surface

quality.

Non-uniform clearance and spray angle lead to heavy forma-

tion of paint mist and thus to an uneven surface.

– End the spraying procedure outside the target area.

Never spray the container completely empty. When the suc-

tion tube no longer immerses in the spray material, the spray

jet will break off, resulting in a non-uniform surface.

When coating material builds up on the nozzle and air cap,

clean both parts with the corresponding solvent.

Spray material Recommended

dilution

Wood preservatives, mordants/strip-

pers, oils, varnishes, impregnations,

rust-protection primers

undiluted

Disinfectants, plant protectants, water,

wallpaper stripper

undiluted

Solvent or water-dilutable paints,

primers, radiator paint, automotive top

coats, thick-coat finishes

At least 10 %

diluted

Amount of spray material [ml] 200 300 400 500

Paint thinner [ml] 20 30 40 50

For spray jobs on horizontal

surfaces/objects

toward the front in nozzle

direction

For spray jobs overhead toward the rear in handle

direction

OBJ_BUCH-420-002.book Page 17 Tuesday, August 23, 2011 12:08 PM