14 | English

1 619 929 K18 | (18.11.11) Bosch Power Tools

plugswithearthed(grounded)powertools.Unmodified

plugs and matching outlets will reduce the risk of electric

shock.

fProtect the machine from rain and moisture. The pene-

trationofwaterinapower tool increasestheriskof electric

shock.

fDo not misuse the cord. Never use the cord for carry-

ing, pulling or unplugging the power tool. Keep cord

away from heat, oil, sharp edges and moving parts.

Damaged or entangled cords increase the risk of electric

shock.

fWhen operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use. Use of a cord suitable

for outdoor use reduces the risk of electric shock.

fWhen operating the power tool in damp/moist environ-

ments is unavoidable, use a residual current device

(RCD).Use of a residual current device reduces the risk of

electric shock.

Personal safety

fUse safety equipment. Always wear eye protection.

Safety equipment such as dusk mask, non-skid safety

shoes, hard hat, or hearing protection used for appropri-

ate conditions will reduce personal injuries.

Use and care of the power tool

fDo not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

fStore idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

fUse the power tool, accessories and application tools

etc. in accordance with these instructions, taking into

account the working conditions and the work to be per-

formed. Use of power tools for operations different from

those intended could result in a hazardous situation.

Service

fHave yourpower tool servicedbya qualified repairper-

son using only identical replacement parts. This will en-

sure that the safety of the power tool is maintained.

Safety Warnings for Fine-spray Systems

fUse only paints/coatings as specified under Intended

Use. Paints/coatings that are not approved (e.g., varnish,

oil-based paint, etc.) can damage the fine-spray system.

fDo not direct the fine-spray system against yourself,

other persons or animals.

fObserve possible hazards of the paint/coating. Ob-

serve the manufacturer’s working instructions for the

paints/coatings.Themanufacturer’sinstructions mustbe

followed in order to reduce the risk of injury.

fKeep the plug of the mains cord and the trigger switch

of the spray gun clear of paint and other fluids. Never

hold the cord by its connectors to support it. Failure to

follow the instruction can lead to electric shock.

fUse only water-based materials for cleaning. Volatile

solvents create an explosive environment and can damage

the fine-spray system.

fSupervise children. This will ensure that children do not

play with the fine-spray system.

fChildren or persons that owing to their physical, senso-

ryormental limitationsor to their lack of experience or

knowledge, are not capable of securely operating the

fine-spray system, may only use this fine-spray system

under supervision or after having been instructed by a

responsible person. Otherwise, there is danger of operat-

ing errors and injuries.

Products sold in GB only: Your product is fitted with an

BS 1363/A approved electric plug with internal fuse (ASTA

approved to BS 1362).

If the plug is not suitable for your socket outlets, it should be

cut off and an appropriate plug fitted in its place by an author-

ised customer service agent. The replacement plug should

have the same fuse rating as the original plug.

The severed plug must be disposed of to avoid a possible

shock hazard and should never be inserted into a mains sock-

et elsewhere.

Productssold in AUS and NZ only: Use a residual current de-

vice (RCD) with a rated residual current of 30 mA or less.

Product Description and Specifica-

tions

Read all safety warnings and all instruc-

tions. Failure to follow the warnings and in-

structions may result in electric shock, fire

and/or serious injury.

Intended Use

The power tool is intended only for spraying water-based dis-

persion wall paint in enclosed locations.

Use the machine only when you can fully assess all functions

and handle them without limitation, or after having received

appropriate instructions.

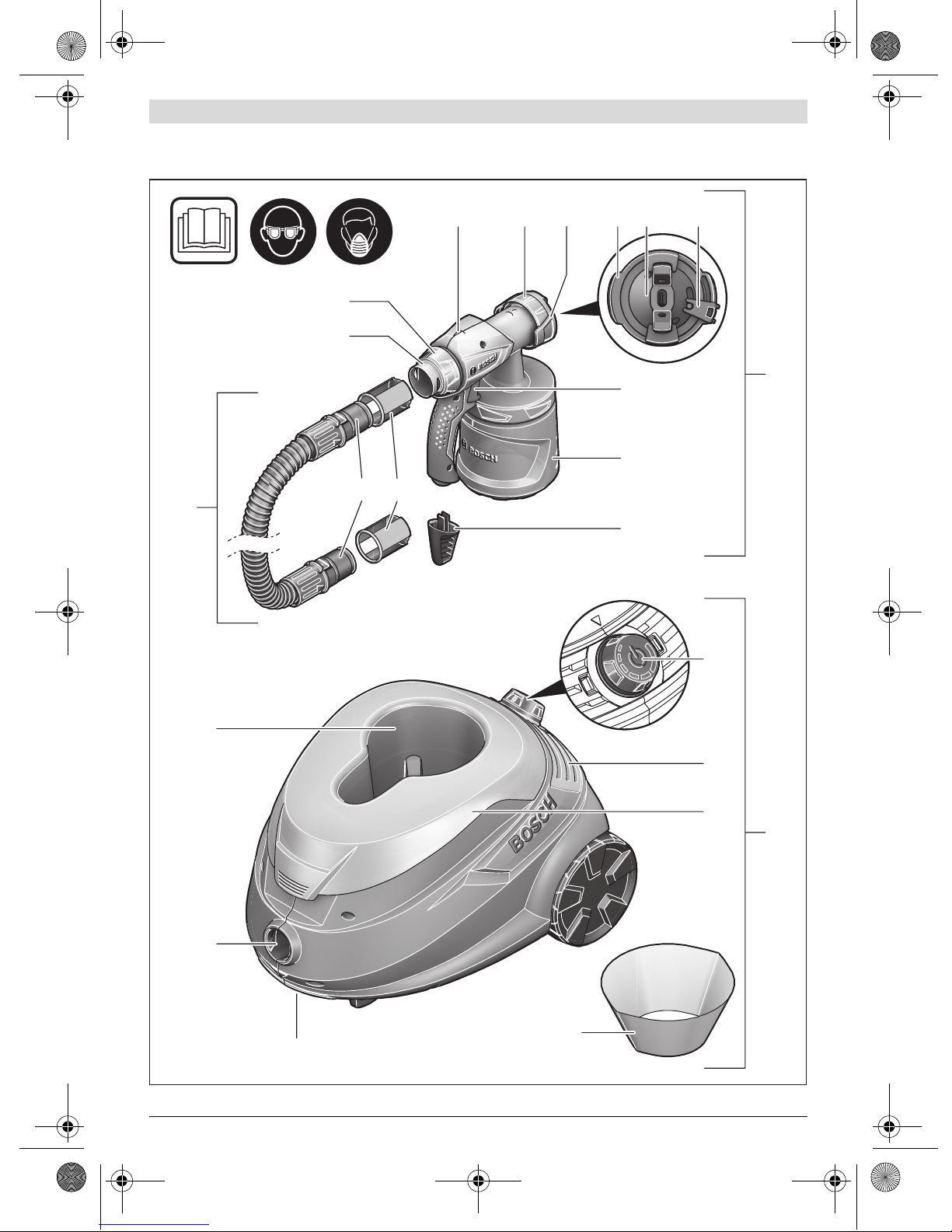

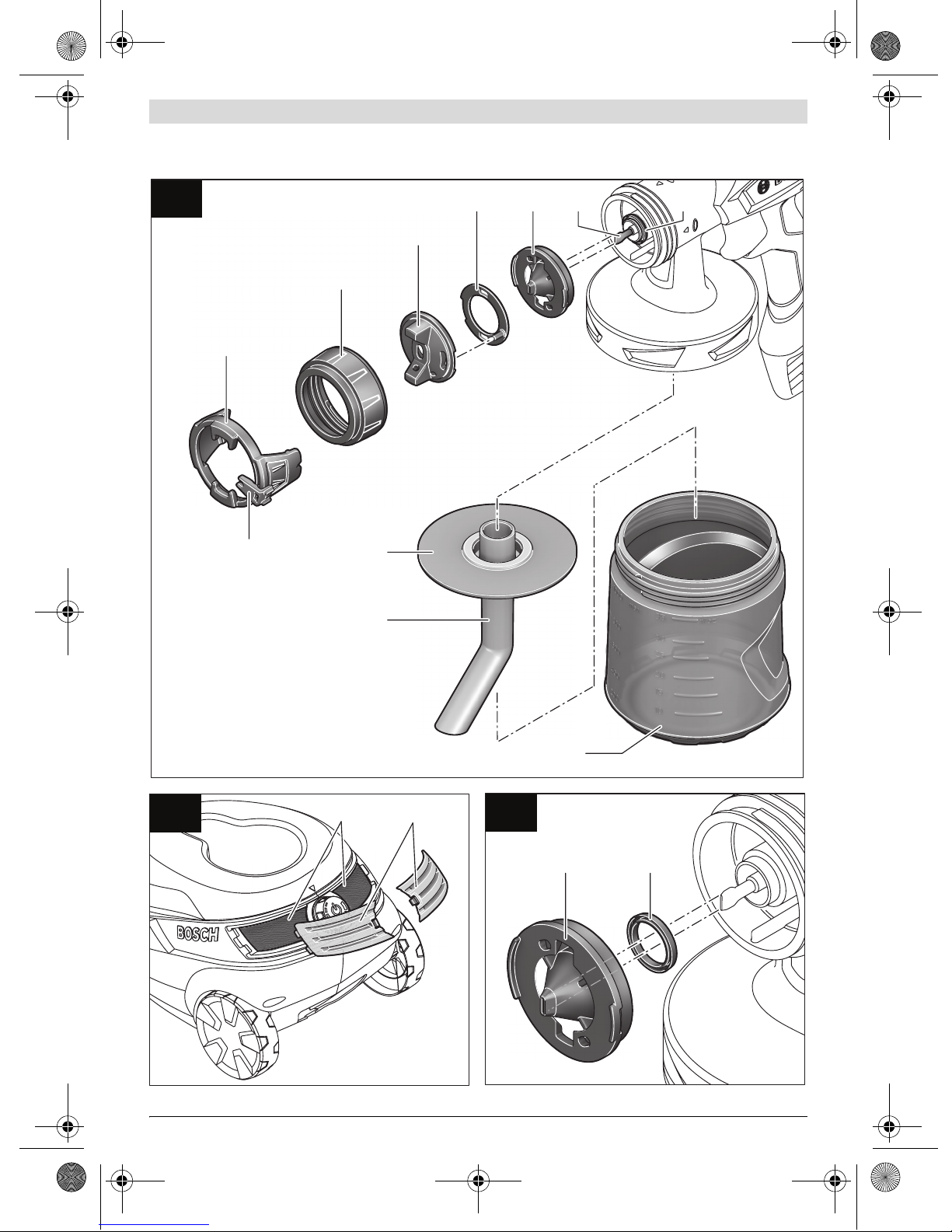

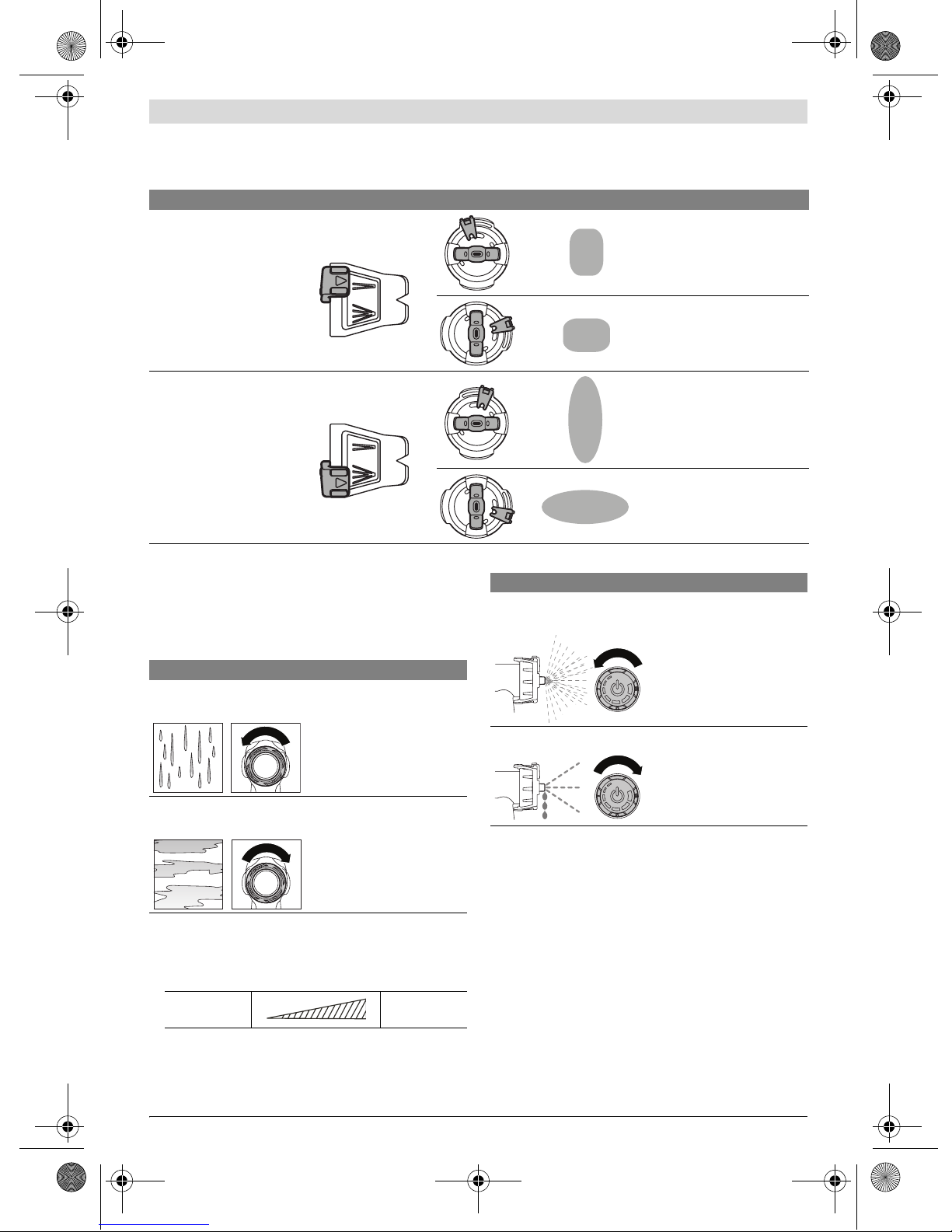

Product Features

The numbering of the components shown refers to the repre-

sentation of the power tool on the graphic pages.

1Spraygun

2Adjusting lever for the spray-jet width

(compact jet/wide jet)

3Air cap

4Adjusting ring for spray jet

(horizontal/vertical)

5Union nut

6Mark for SDS connection

7Thumbwheel for spraying capacity

OBJ_BUCH-1543-001.book Page 14 Friday, November 18, 2011 9:16 AM