A5Q00036139_a_-_- - 4 -

en

1. Application

The ISN-MS-90 seismic detector provides reliable protection against

break-in attempts on safes, automatic cash dispensers, night deposit

boxes, lightweight safes (LWS), vaults and steel/concrete modular

strongrooms. Intelligent signal processing enables the level of

detection sensitivity to be custom-set, thereby reducing the risk of

false alarms. The removal monitoring system

2

Ewill detect the

forcible removal or opening of the detector.

Installation, programming and commissioning must be

performed by specialists.

For modular vaults, see Chapter 11.

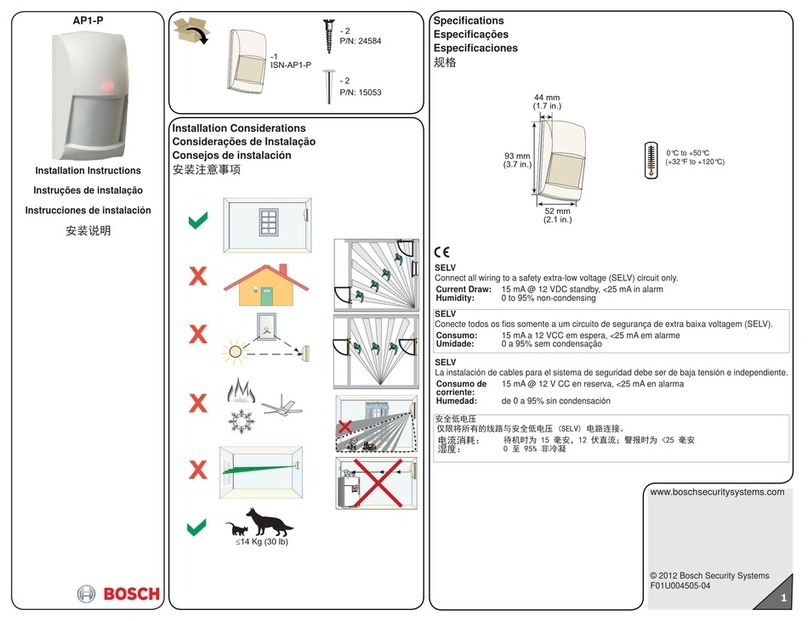

2. Coverage area

The area monitored by the detector is referred to as the coverage

area

3

. It covers the area around the detector with an operating

radius indicated in

r

. Detectors should be positioned and spaced

apart, as indicated by (a), so that they cover the entire area to be

monitored.

Doors and joints impair transmission, so additional detectors must be

installed at these points. Tightly sealed corners and edges reduce the

range by 1/4. As a result, corners and edges on steel vaults must be

seamlessly welded. Incorrect positioning can reduce the coverage

area.

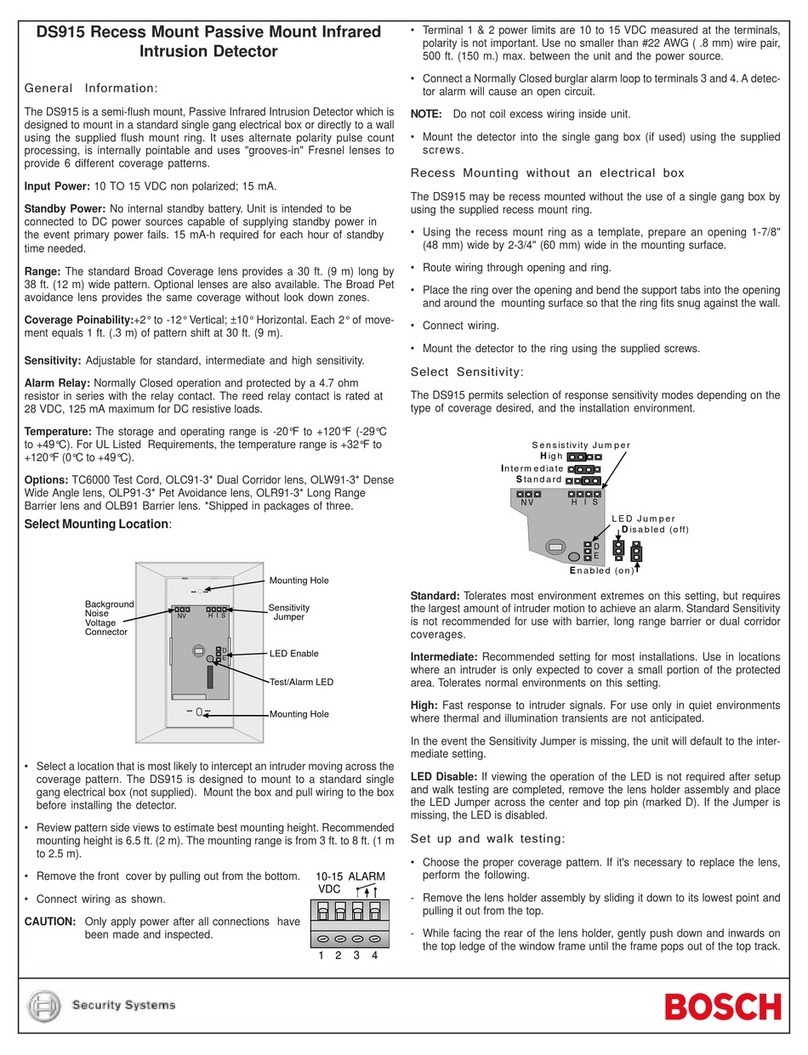

3. Attachment

There must be a direct connection between detector and

mounting base. Paint, varnish, dirt, silicone or similar

materials will impede this and must be removed.

A)In the case of steel walls

4

A, the detector should be mounted

directly on the flat, bare metal surface. Attach two M4x6 threads.

Use the drilling template as a positioning guide.

B) In the case of uneven or reinforced steel walls, the mounting plate

4

B(accessory ISN-GMX-P0) should be mounted using two fillet

welds. Mount the detector.

C) In the case of concrete walls

4

C, the mounting plate (accessory

ISN-GMX-P0) should be screwed in using a central metal plug.

Mount the detector.

D) Watertight housing

4

D(accessory* ISN-GMXW-G0).

E) For recessed mounting

4

E, screw the wall recess plate

(accessory ISN-GMX-W0) to the mould (1). Push the installation

conduit into the polystyrene. After filling the recess, remove the

polystyrene and the threaded bolt and cut the installation conduit

(2). Mount the detector and cover (3).

F) For floor mounting

4

F, create an appropriately sized recess, place

the floor box (accessory ISN-GMX-B0) inside and level it using two

metal plugs, a threaded bolt and lock nuts. Feed in the installation

conduits and fill the recess with liquid concrete. Place the detector

on a 2 mm distance plate, then attach the cover.

G)

Swivel plate (

4

G

) (accessory

*

ISN-GMX-P3S/ISN-GMX-PZ) including

adapter.

H) Mounting with a gusset shoe (

4

H) (accessory*ISN-GMA-S6).

* The installation instructions are supplied with the accessory.

4. Accessories

ISN-GMX-D7 Anti-drilling foil

Glue the foil to the inside of the cover

5

Cand connect the cable to

terminal

2

Dinstead of the jumper.

ISN-GMX-S1 Test transmitter

6

Screw in the test transmitter and connect the cables

2

C(M4x6 mm

thread).

ISN-GMS-W7 SensTool (terminal

2

F)

The software enables:

- Settings to be made for the application, impact sensitivity, digital

filters, polarity of TEST, REMOTE and alarm relay inputs, and

temperature monitoring

- Detector signals to be evaluated

- Results to be saved

5. Mounting the detector

Carefully open the detector

5

Aand screw it to the prepared

mounting base using two screws

5

B. Wire the connection cables to

terminal

2

Has shown in diagram

7

and attach a cable grip

2

I.

Connect the accessories and program the detector.

en

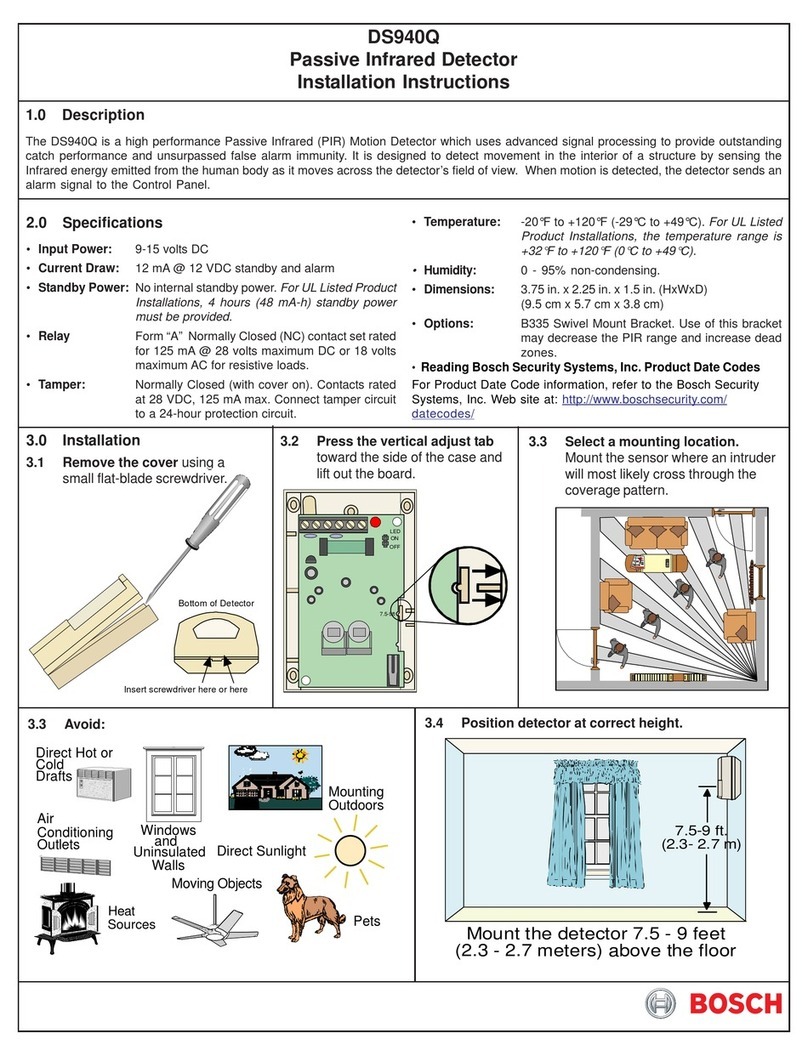

6. Programming

Application setting

2

G

Make the mounting base and operating radius settings.

The specified operating radius applies to attack with an oxygen lance;

if attacked with a mechanical tool (e.g. a drill) the value may be as

much as three times higher. The specified operating radius is a

guideline which is heavily influenced by the characteristics of the

substrate.

Operating

radius

r

Mode Fixed Fixed Fixed

USER MODE

Steel -- 2 m 1,5 m 1

*

/ 1,5 / 2 m

LWS -- -- -- 1,5 / 2 m

Concrete 4 m -- -- 2,5 / 4 / 5 m

*

Factory setting in USER MODE. Change with SensTool.

Sensitivity

7

(terminal 7)

Only apply for a short time. Any reduction in sensitivity must

comply with applicable regulations (e.g. VdS in Germany). )

Factory setting: Low active

Sensitivity is reduced to 1/8 for the duration of the remote signal.

Application: Prevention of alarm triggering where loud functional

noises prevail.

Test input

7

(terminal 4)

The ISN-GMX-S1 test transmitter

6

is activated via the test input. If

the detector is functioning correctly, it will trigger an alarm (trigger time

<3 s). Factory setting: Low active

7. LED display

The red LED

2

Bflashes during commissioning and initialisation. In

the event of an alarm, the LED lights up for approx. 2.5 s.

8. Commissioning

- Switch on voltage - Wait 30 s - Detector is ready for operation.

- Functional check: Trigger an alarm to test (e.g. scratch with a

screwdriver or switch on the test transmitter).

- Check for interference using SensTool or a measuring instrument

(Ri 20 k) at terminal 1 (0 V) and TP

2

Afor the analog integrator

signal: - Quiescent level ......................................... 0 V

- Integration start......................................... 1 V

- Alarm threshold (w/o load)........................ 3 V

- Carefully close the cover and screw it in place.

9. Maintenance

The function of the detector and its mounting should be checked at

least once a year.

10. Technical data

Supply voltage (nom. 12 VDC) ............................Vcc = 8 to 16 VDC

Current consumption (at 12 VDC, quiescent)................ Ityp. = 3 mA

Alarm condition ......................................................... Imax. = 5 mA

Alarm output, terminals 14+15:

Semiconductor relay.......................Opens on alarm + low voltage

Contact load...................................... 30 VDC/100 mA, ohmic load

Series resistance .................................................................. <45

Alarm holding time ..................................................................2,5 s

Electronic alarm output, terminal 12:

Open collector.........................................................Alarm = 0 VDC

Short circuit strength........................................................ 16 VDC

Sabotage surveillance:

Tamper, terminals 10+11................................................................

Microswitch, cover + floor ...................... Opens on sabotage

Contact load .................................................30 VDC/100 mA

Anti-drilling foil in cover.....................................Sabotage ÖAlarm

Test input, terminal 4 ............................. Low <1,5 V/High >3,5 VDC

Remote input, terminal 7.................. Low <1,5 V/High >3,5 VDC

Operating temperature...........................................-40º to +70ºC

Storage temperature..............................................-40º to +70ºC

Air humidity (EN 60721), non-condensing .........................<95%

Approvals........................See type plate (

5

D) on housing cover