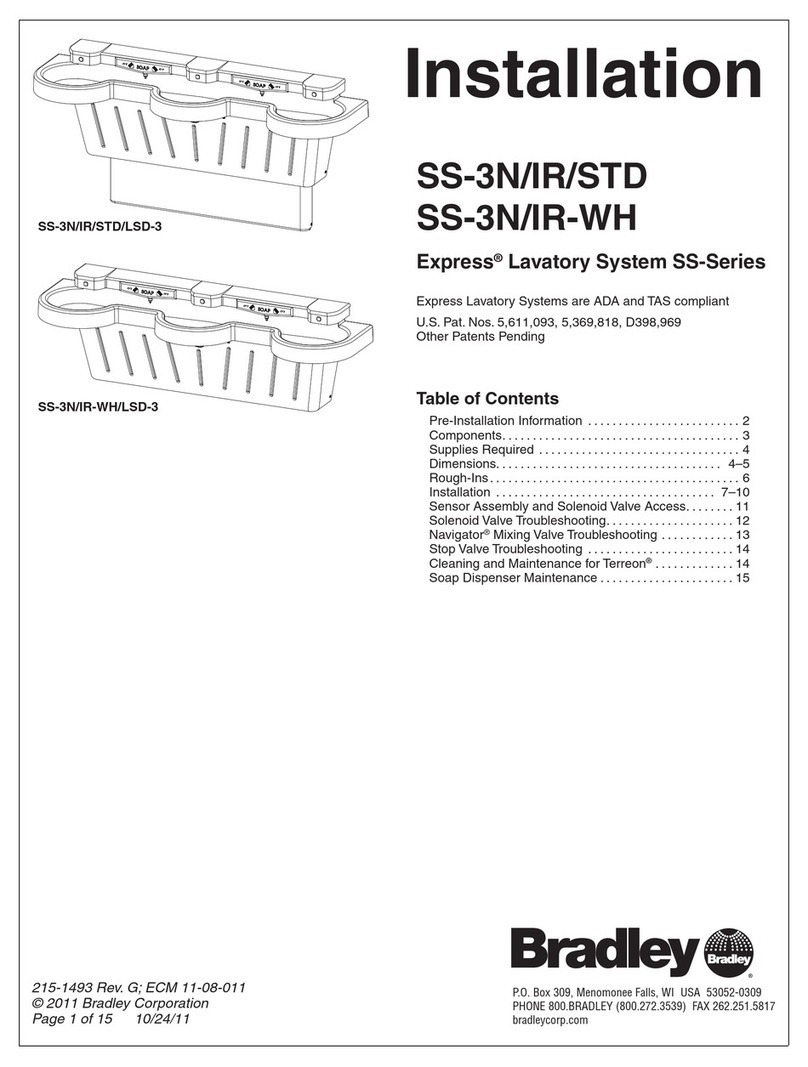

Bradley Express SS Series User manual

Other Bradley Bathroom Fixture manuals

Bradley

Bradley Express SS Series User manual

Bradley

Bradley Verge LVLD Series User manual

Bradley

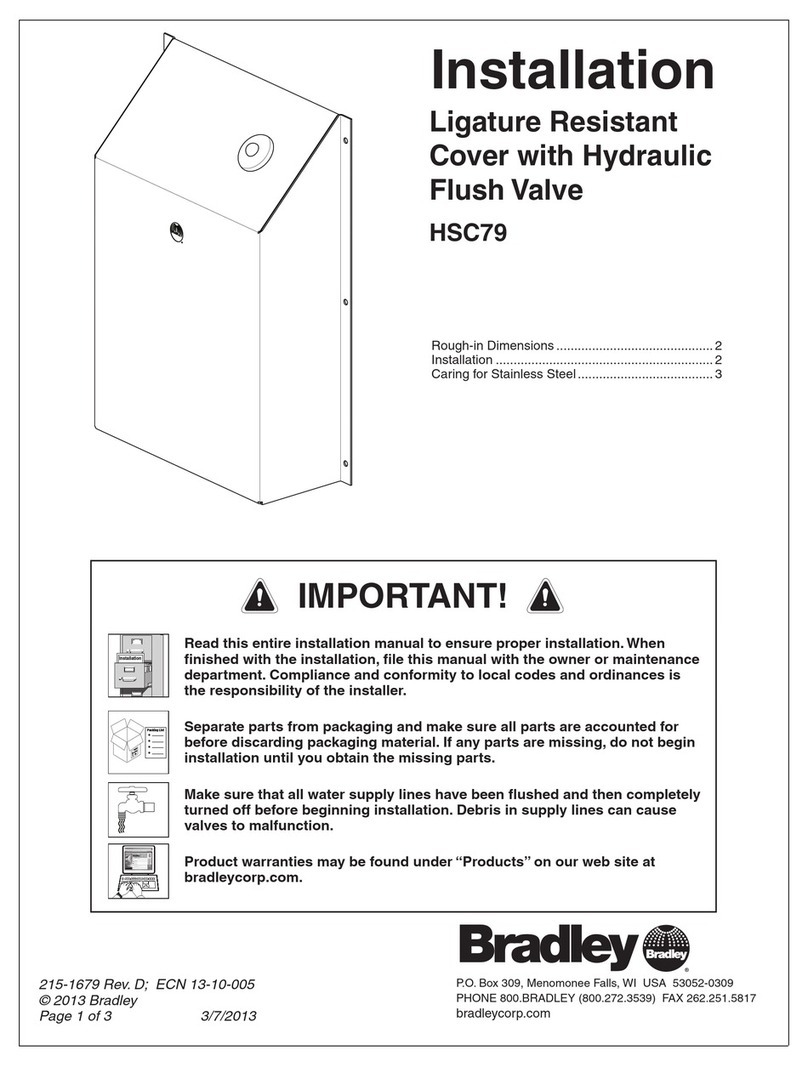

Bradley HSC79 User manual

Bradley

Bradley Terreon Deep Bowl TDB3100 Series User manual

Bradley

Bradley 500 Series User manual

Bradley

Bradley HN-250 User manual

Bradley

Bradley s19314 series User manual

Bradley

Bradley Express MG Series User manual

Bradley

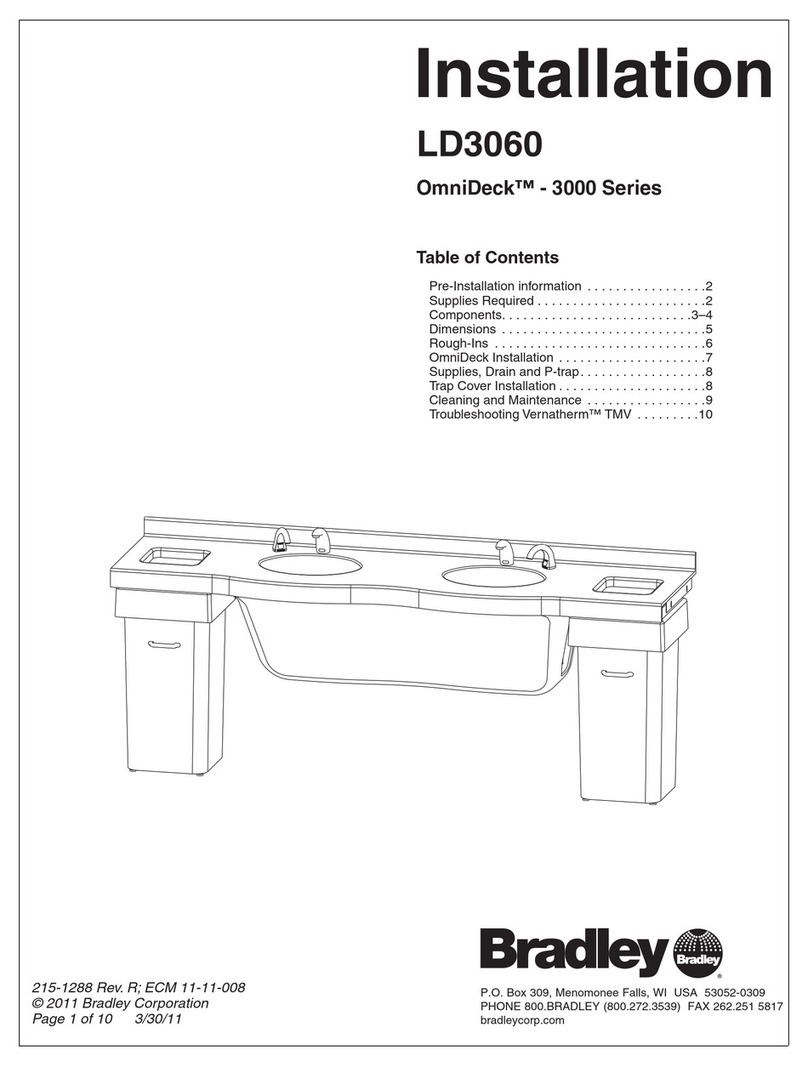

Bradley OmniDeck 3000 Series User manual

Bradley

Bradley SXWS9557FM User manual

Bradley

Bradley TouchTime 1C User manual

Bradley

Bradley S19-280D User manual

Bradley

Bradley 400 Series User manual

Bradley

Bradley S19-120 User manual

Bradley

Bradley TDB3105 User manual

Bradley

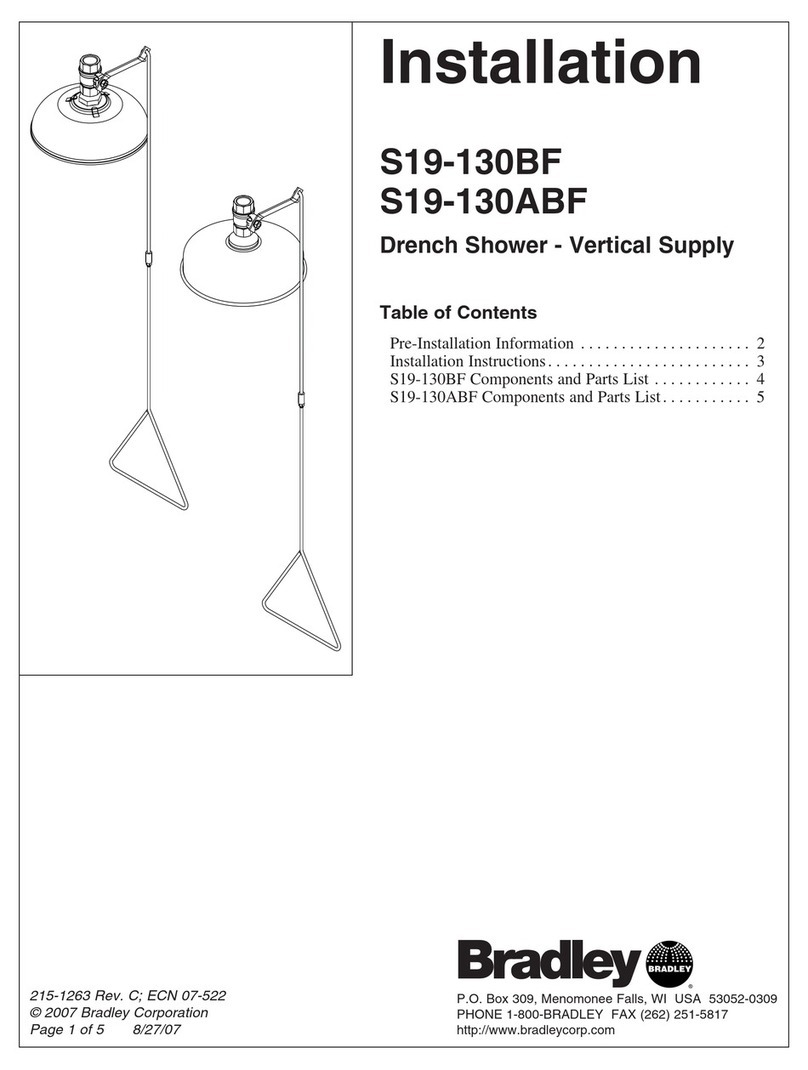

Bradley S19-130BF User manual

Bradley

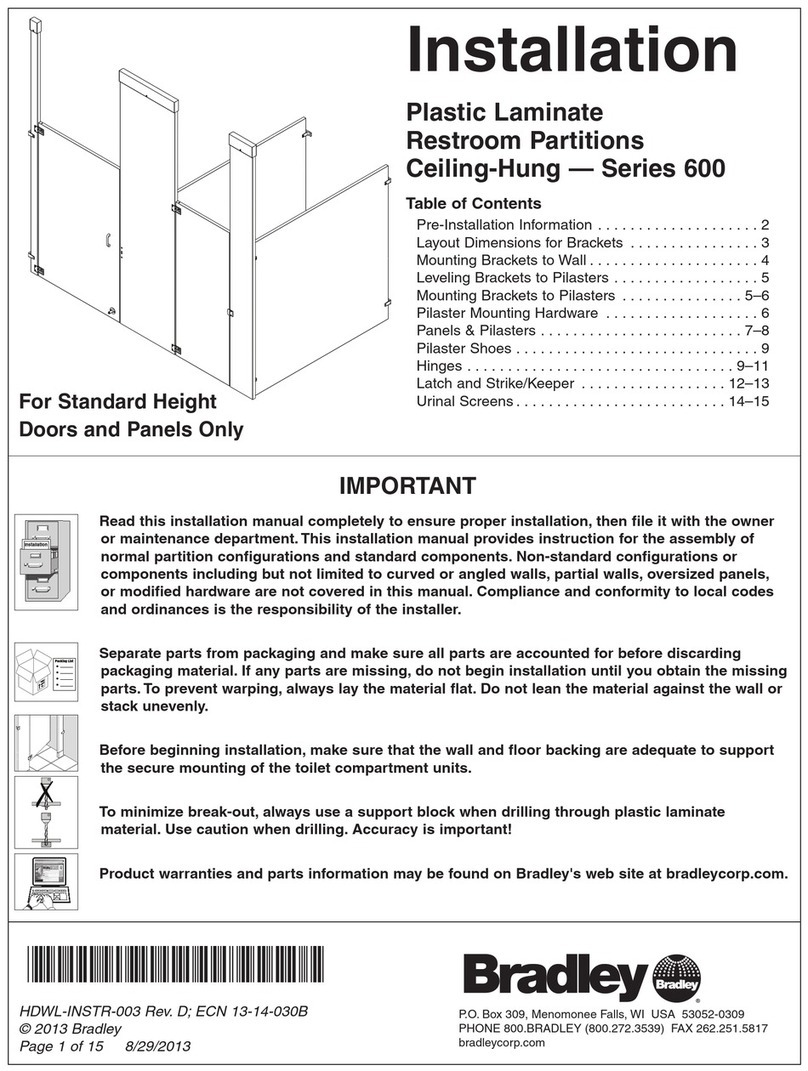

Bradley 600 Series User manual

Bradley

Bradley S19-310SS User manual

Bradley

Bradley LOFT Series User manual

Bradley

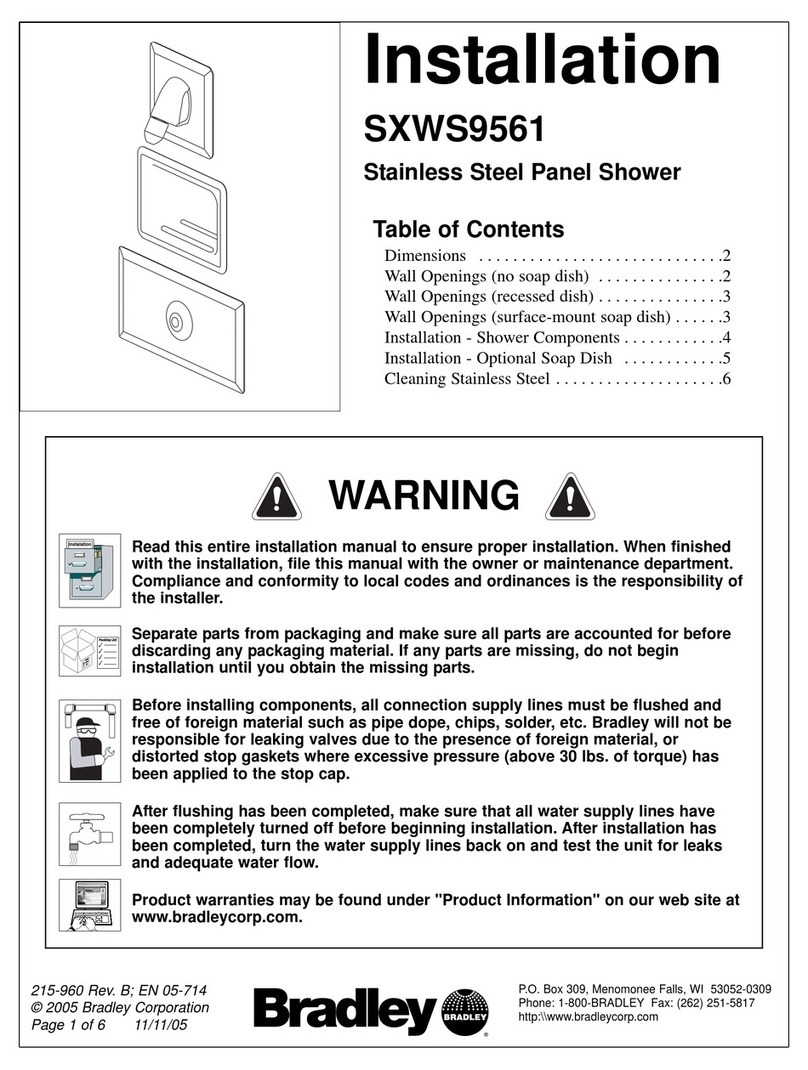

Bradley SXWS9561 User manual