BRASSELER USA EndoDrive PLUS User manual

Please Read this operation manual carefully before use and keep for future reference.

OPERATION MANUAL

OM-E0202E 001

Motor Handpiece System for Root Canal Enlargement

Classifications of equipment

• Type of protection against electric shock :

– Class II equipment :

• Degree of protection against electric shock :

– Type B applied part :

• Method of sterilization or disinfection recommended by the manufacture

– See 8. Sterilization

• Degree of protection against ingress of water as detailed in the current edition of IEC 60529 :

– Foot Control (Option) : IPX1 (Protected against vertically falling water drops)

• Degree of safety of application in the presence of a flammable anaesthetic mixture with air or

with oxygen or nitrous oxide :

– EQUIPMENT not suitable for use in the presence of a flammable anaesthetic mixture with air

or with oxygen or nitrous oxide.

• Mode of operation :

– Continuous operation

1

Thank you for purchasing the EndoDrive PLUS.

This product should be used by qualified personnel for dental purposes only.

This product is used primarily for root canal enlargement. Read this Operation Manual carefully before

use for operation instructions, care and maintenance. Keep this Operation Manual for future reference.

Read these safety cautions thoroughly before use and operate the product properly.

These indicators are to allow you to use the product safely and prevent danger and harm to you

and others. These are classified by degree of danger, damage and seriousness. All indicators

concern safety, and should be followed.

Cautions for handling and operation

CONTENTS

Cautions for handling and operation ··· 1

1. FEATURES ·········································· 3

2. SPECIFICATIONS ································ 4

3.

NAME AND FUNCTION OF EACH PART....

4

4. HOW TO CONNECT EACH PART ······· 8

5. HOW TO USE······································ 9

6. CONVENIENT FUNCTIONS ···············12

7. CLEANING ····································14

8. STERILIZATION ····························14

9. CHANGING BATTERIES ················15

10. ERROR CODE ·······························16

11. TROUBLESHOOTING ···················17

12. WARRANTY ··································19

13. DISPOSING PRODUCT ··················19

DANGER

WARNING

CAUTION

NOTICE

Explains an instruction where death or serious injury may occur.

Explains an instruction where bodily injury or damage to device may occur.

Explains an instruction where possibility for minor to medium bodily injury or

damage to device may exist.

Explains an instruction that should be observed for safety reasons.

Classification Degree of danger or damage and seriousness

2

• Use the specified batteries for this product. Never use any other batteries than those that

NSK specifies.

DANGER

• Intended use by dental professional, only.

• Do not spill water or a chemical solution onto or into the motor handpiece or control unit as it may result in fire or

electric shock due to a short-circuit or breakage due to rusting.

• Keep away from patients with cardiac pacemakers.

• If you should notice battery fluid leak within the control unit, deformation of the control unit casing or partial

discoloring, immediately stop use and contact Brasseler USA.

• Should the leaking battery fluid get into your eyes, immediately wash eyes thoroughly with clean water and see

your doctor. Failure to do so may result in loss of sight.

• Should the battery fluid leak and adhere to skin or clothing, immediately wash the exposed skin thoroughly with

clean water and completely wash away the fluid. Failure to do so may result in skin irritation.

• If the product will not be used for a long period, remove the batteries from the product to avoid fluid leak.

• When installing the product, provide space of approximately 10cm around the Control Unit for easy access to the

inlet and the Power Cord

• The system may present a possibility of malfunction when used in the presence of electromagnetic interference

wave. Do not install the system in the vicinity of the device which emits magnetic waves.

• Always consider the safety of the patient when using this product.

WARNING

• Exercise sufficient care in using the product by giving patient safety first priority.

• The product is to be used only for dental treatment by qualified personnel.

• Only use the EndoDrive Plus adapter. Never use any other AC adapters.

• Observe the allowable rotation speed which the file manufacturer specifies for use.

• Do not use a bent, damaged, deformed or non-ISO-conforming file. Using such a file may result in personal

injury due to its unexpected breaking or flying off during rotation.

• Do not use or leave the product in a high-temperature environment such as under strong direct sunlight, in a car

under a blazing sun, by a fire, or near a stove.

• Check the product before use, paying attention to looseness, vibration, noise and temperature (heat generation).

If any abnormal condition is found even slightly at that time, immediately stop use and contact Brasseler USA.

• Do not allow any impact on to the Product. Do not drop the Product.

• Do not attempt to disassemble the product or tamper with the mechanism.

• Always clean the shank of the file to be installed. Allowing dirt to enter the chuck could cause loss of

concentricity and deterioration of chucking force.

• Before changing the head or File, turn off the power of the motor handpiece. Changing with the power kept on

may cause unintended rotation.

• Pay attention to the direction of batteries when replacing. Forcing batteries in the wrong direction may cause

damage and fluid leakage due to a short circuit.

• Do not allow conductive materials such as wires, safety pins, etc., to enter into the battery case.

• If chemical, solvent or antiseptic solution is deposited on this product, immediately wipe it away. Discoloration or

deformation may occur if not removed.

• The system functions normally in the environment where the temperature is at 10-40°C (50-104°F), humidity at

10-85% RH, atmospheric pressure at 700-1060hPa, and no moisture condensation in the Control Unit. Use at

outside of these limits may cause malfunction.

• EndoDrive PLUS needs special precautions regarding EMC and needs to be installed and put into service

according to the EMC information.

• Portable and mobile RF communications equipment can affect EndoDrive PLUS.

• The use of ACCESSORIES, transducers and cables other than those specified, with the exception of

transducers and cables sold by the manufacturer of EndoDrive PLUS as replacement parts for internal

components, may result in increased EMISSIONS or decreased IMMUNITY of EndoDrive PLUS.

CAUTION

3

• Compact design.

• Able to operate for approx. 2 continuous hours at the rated load. (Dependent upon use conditions.)

• A large LCD panel enhances ease of use.

• Programmable up to 9 memory settings.

• The auto reverse function is activated depending on the load. A wide variety of functions such as “auto reverse”,

“auto stop” and “auto reverse off” are available. Combined with such functions nine different operation programs

are memorable.

• The rotation of the motor handpiece can be activated by the ON/OFF button of the motor handpiece or the Foot

Control (optional).

• The motor handpiece can be turned on and off by pressing the ON/OFF button alternatively. In addition, ON by

keep depressed and OFF by releasing it is possible.

• The motor handpiece softly starts. Since it makes a brief stop before it starts in the reverse rotation, there are no

vibration and shocks during this change over.

• The built in feedback circuit maintains rotation at a constant speed even when the load on the motor handpiece

changes.

• Has energy saving feature. The power of the motor handpiece automatically turns off when not being used for 10

minutes. (Auto power-off function)

• The contra angle heads provided for this product are all autoclavable up to 135°C (excluding the motor

handpiece).

1. FEATURES

• During rotation, the motor handpiece and the motor handpiece cord may affect computer and LAN cable. Noise

could be heard during operation near a radio receiver.

• The motor handpiece consumes electricity very slightly even when the power supply is off. In addition,

fully-charged rechargeable batteries, in general, discharge gradually over time even though it is not used. It is

recommended to recharge the batteries just before use.

• When the motor handpiece stops automatically by detecting a low battery voltage, turning on the power again

after a while may not detect the low voltage immediately. This is not a failure, but due to battery characteristics.

The voltage drop does not coincide with the remaining battery capacity.

• Recharge rechargeable batteries after they deplete as much as possible. Repeating short-time use and

subsequent recharging may shorten their operating time due to the “memory effect.” Batteries may recover after

repeating complete discharge and full charge for a few times. (This product is equipped with a “Refresh Mode”

for this purpose.)

• The used Nickel Metal Hydride Batteries are recyclable, but their disposal may sometimes not be permitted by

the country. Return them to Brasseler USA.

• When disposing of the control unit and Foot Control (Option), follow the instructions of your local government for

disposal, as they contain materials which may become industrial waste.

• When discarding the contra angle head and motor handpiece, dispose of them as medical waste.

• Users are responsible for operational control, maintenance and inspection.

• Store the system in the place where the temperature is at -10-60°C (14-140°F), humidity at 10-85% RH,

atmospheric pressure at 500-1060 hPa, and the system is not subject to air with dust, sulfur, or salinity.

• When trouble is found, contact Brasseler USA.

• This product does not consider patient’s age (except infants), gender, weight or nationality.

• No special training is required for this device.

• EndoDrive PLUS should not be used adjacent to or stacked with other equipment and that if adjacent or

stacked use is necessary, EndoDrive PLUS should be observed to verify normal operation in the

configuration in which it will be used.

NOTICE

4

3. NAME AND FUNCTION OF EACH PART

< Control Unit >

2. SPECIFICATIONS

Model

Rated input

Output

Charging time

Dimensions

Weight

NE131

DC20V 0.5A

DC7V 0.4A

5hours approx.

W92 x D148 x H124mm

456g

< AC Adaptor >

Model

Rated input

Dimensions

Weight

NE169

AC120V 60Hz

AC230V 50/60Hz

W70 x D110 x H58mm

120V : 934g

230V : 974g

< Motor Handpiece >

Model

Rated input

Dimensions

Weight

EM13M

DC7V 0.4A

Ø20 × L108mm

92g

( including motor handpiece cord )

Fig. 1

2

3

8

10

9

1

12

4

5

6

7

11

Control Unit

Operation Panel

* See Fig. 2 “Operation Panel and LCD Panel. ”

LCD Panel

· See Fig. 2 “Operation Panel and LCD Panel.”

· Error codes are displayed.

Power Cord Connector

The AC adapter is connected.

Foot Control Connector

The foot control (option) is connected.

1

2

3

4

5

Motor Handpiece Connector

The motor handpiece is connected.

AC Adaptor

Motor Handpiece

Contra Angle Head (20:1)

Handpiece Stand

Spray Nozzle

· This is used for lubrication.

Foot Control (Optional)

6

7

8

9

10

11

12

5

• POWER Key

• Press the POWER key for more than one second to turn on the power and the LCD panel lights.

• Press the POWER key for more than one second while the power is on, turns off the power and the LCD panel

turns off.

• SPEED Key

• The rotation speed can be changed.

• If the speed is to exceed the upper limit or fall below the lower limit, the alarm sounds.

LCD

The present rotation speed is displayed. The unit is (min-1). “ or ”

is displayed depending on the rotation speed.

Operation Panel and LCD Panel.

Fig. 2

(LCD Panel)

This indicates that all displays are lighted.

• TORQUE Key

• The torque limit values can be changed.

• If the speed is to exceed the upper limit or fall below the lower limit, the alarm sounds.

LCD

The present torque limit value is displayed. The unit is (Ncm). When it reaches

the maximum value, “ ” is displayed.

REVERSE KeyREVERSE Key

TORQUE KeyTORQUE Key

PROGRAM KeyPROGRAM Key

SPEED KeySPEED Key

AC IN LampAC IN Lamp

CHARGE LampCHARGE Lamp

AUTO REVERSE KeyAUTO REVERSE Key

POWER KeyPOWER Key

GEAR RATIO KeyGEAR RATIO Key MEMORIZE KeyMEMORIZE Key

(Operation Panel)(Operation Panel)

6

• PROGRAM Key

• A program can be selected.

LCD

The present program number is displayed. The program number is available from 1 to 9.

High sound volume

Low sound volume

Forward Rotation (F).

Reverse Rotation (R).

Limited OFF (The alarm sounds with a small sound volume at the time of confirmation and error, but it

will not sound at the time of reverse rotation or when the torque limit has been reached.)

The present gear ratio is displayed. The gear ratio is available at (1:1, 4:1, 10:1, 16:1 and 20:1).

• REVERSE Key

• The rotational direction of the file can be changed by this key. It can also be changed while the file is in motion.

• The alarm sounds during reverse rotation.

LCD

The current rotational direction is displayed.

• GEAR RATIO Key

• A gear ratio can be selected by this key. If the correct gear ratio is selected according to the contra angle head in

use, an adequate rotation speed and torque limit value can be set.

• The gear ratio cannot be changed while the file is in motion.

LCD

• The alarm sound volume can be adjusted. (Refer to P.14 6. (5) “Alarm Sound Volume Control”)

LCD

The present alarm mark is displayed.

7

The mark of remaining amount of batteries indicates a voltage. When load is applied to the motor handpiece,

the mark of remaining amount of batteries appears to become lower.

NOTICE

• AUTO REVERSE Key

The auto reverse mode can be selected by this key. (Refer to P.11 “ Auto Reverse Function.”)

LCD

The present auto reverse mode mark is displayed.

• MEMORIZE Key

This key can preset program setting (rotation speed, torque limit value, gear ratio, auto reverse mode) and selecting

the program. (Refer to P.12 6. (1) “Program”)

• CHARGE Lamp (Orange)

This lamp lights or flashes while the batteries are being charged, in the battery refresh mode, (Refer to P.13 6. (3)

“Battery Refresh”) or an error has occured, regardless of the ON or OFF position of the power.

LCD

The battery mark will always be displayed even if the unit is powered OFF. The mark will be animated when the

batteries are being charged or in the refresh mode (Refer to P.13 6. (3) “Battery Refresh”).

• AC IN Lamp (Green)

The lamp light will always be displayed when power is supplied by the AC adapter even if the unit is powered OFF

AUTO REVERSE If the load is removed after auto reverse rotation, it returns to the normal rotation again.

Full charge or nearly full charge.

About 30-80% remains.

Less than about 30% remains. In this state, the auto reverse function may not activate. (Refer to P.11

“ Auto Reverse Function”)

Batteries are drained or remarkably low voltage. Charge the batteries.

AUTO STOP If the load is removed after autoreverse rotation, it stops.

AUTO REVERSE OFF Auto reverse rotation is not activated.

*There is no display.

Fig. 4

8

(1) Connecting Motor Handpiece

Align the mark of the Motor Handpiece Cord Plug of the

motor handpiece with the mark of the motor handpiece

connector and insert the plug until it locks. (Fig. 3)

(2) Connecting AC Adapter

Insert the jack of the AC adapter into the power connector

with the mark of the jack down. (Fig. 4)

(3) Connecting Foot Control (Option)

Securely insert the plug of the Foot Control (Option) into

the Foot Control Connector with the mark of the plug

down. (Fig. 5)

* The Foot Control is optional and is not required to

operate the EndoDrive PLUS.

4. HOW TO CONNECT EACH PART

To remove the plug, hold the plug ring and pull it out.

NOTICE

• Bar Display

LCD

The bar display graph which shows the degree of load applied to the motor while

the file is in motion.

Fig. 3

Fig. 5

Foot Control (option) PlugFoot Control (option) Plug

Foot Control ConnectorFoot Control Connector

Motor Handpiece

Cord Plug

Motor Handpiece

Cord Plug

Motor Handpiece

Connector

Motor Handpiece

Connector

Ring

Jack of the AC AdapterJack of the AC Adapter

Power ConnectorPower Connector

Ring

9

(1) Charge (if batteries are used)

1) Insert the AC adapter plug into a power supply.

2) Confirm the AC IN lamp light is green.

3) The internal microcomputer checks the voltage of the batteries and starts charging, if necessary. If it starts

charging, the CHARGE lamp lights, and the mark of the remaining amount of the batteries on the LCD panel will

be animated.

* There is no need to turn on the power.

4) When the CHARGE lamp turns off, charging has been completed.

5. HOW TO USE

• Do not connect other than AC120V or AC 230V. If it connects to others, it may cause a malfunction.

• Since the AC IN lamp lights up to indicate that the supply power is on, it does not go out even after a charge

is completed. See the CHARGE lamp to check the charging conditions.

• The charging normally takes approx. 5 hours, but it depends on battery use conditions. Older batteries are

especially prone to significantly shorter charging and operating times.

• The temperature of the batteries is measured during charging. Proper charging cannot be preformed if the

charger is placed in an environment which is subject to sharp temperature change (next to window, subject

to direct sunlight, near air outlet or fan heater). Place it in a place where temperature change is minimal.

• Charging may not be started in the following case:

• The temperature of a battery is too low or too high. (less than 0°C (32°F) or more than 40°C (104°F). )

• The temperature of the batteries is executively high or low. (Lower than apporox. 0 degree or higher than

approx. 40 degree)

•A battery is not connected.

• The voltage of a battery is abnormal. (See P.16 10. “ERROR CODE”)

• Batteries are automatically charged depending on conditions, even when the power is on. But when the

motor handpiece is used, charging is suspended to protect the battery.

CAUTION

Fig. 6

AC IN Lamp

CHARGE Lamp

AUTO REVERSE Key

POWER Key

MEMORIZE Key GEAR RATIO Key

TORQUE Key

PROGRAM Key

SPEED Key

REVERSE Key

Contra Angle Head

Positioning Pin Positioning Slots

Motor Handpiece

10

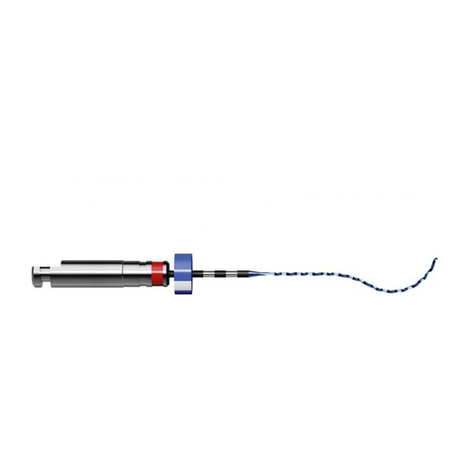

(2) Changing Contra Angle Head

• The contra angle head can be connected with the motor

handpiece at 6 adjustable head positions. Align the

positioning pins of the contra angle head with the

positioning slots of the motor handpiece and insert the

head until they click.

• When removing the contra angle head, pull it straight out.

(Fig. 7)

(3) Mounting and Removing File

<Mounting the File>

1) Insert the file into the chuck until it stops.

2) Lightly turn the file until it engages with the latch

mechanism. Push it inward to click.

<Removing the File>

Depress the push-button and pull out the file.

(4) Preparatory Operations

1) Charge the batteries (Refer to P. 9 5 (1) “Charge (if batteries are used)”) or securely insert the plug of the AC

adapter into a power supply.

2) Hold down the POWER key for more than one second to turn on the power.

3) Select a gear ratio by pressing the GEAR RATIO key. If the correct gear ratio is selected according to the contra

angle head in use, an adequate rotation speed and torque limit value can be set.

4) Select the rotational direction by pressing the REVERSE key. The key changes over to the forward rotation (F) and

reverse rotation (R) each time it is pressed.

5) Select the auto reverse mode by pressing the AUTO REVERSE key. The key changes over to AUTO REVERSE ,

AUTO STOP and AUTO REVERSE OFF each time it is pressed. (Refer to P. 11 “ Auto Reverse Function ” )

• Turn off the power before attaching and detaching the contra angle head.

• Confirm that the contra angle head is securely assembled to the motor handpiece.

CAUTION

The GEAR RATIO key is fast-forwarded, when it is continuously held down.

NOTICE

Fig. 7

Fig. 8* The contra angle head in the figure is MP-F20R.

• Turn off the power before mounting and removing the file.

• After the file is locked in place, lightly pull on the file to make sure the file is locked.

• Always clean the shank of the file to be installed. Allowing debris to enter the chuck could cause loss of

concentricity and deterioration of chucking force.

CAUTION

If the load is kept applied,

the file will rotate in reverse.

When the load is removed,···

Load within the

Torque Limit Value

Reverse RotationForward Rotation Forward Rotation

Further Loading

beyond the preset

Torque Limit Value

11

Auto Reverse Function

When the motor handpiece starts and its load reaches approximately half of the preset torque limit value, the alarm

sounds. (at the time of on the bar display)

The alarm sound changes when the load approaches the torque limit value. (at the time of on

the bar display)

When a further load exceeds the torque limit value, the following 3 modes can be selected:

AUTO REVERSE

The handpiece starts in forward rotation. When a load higher than the torque limit is applied, the file will rotate in

reverse. When the load is removed, the file will return to normal rotation (forward) automatically.

AUTO STOP

The handpiece starts in forward rotation. When a load higher than the torque limit is applied, the file will rotate in

reverse. When the load is removed, the motor rotation stops. If you want it to rotate again, re-press the ON/OFF

key or re-step on the foot control (Optional).

(5) Operation

1) • Start the motor handpiece to pressing the ON/OFF button

briefly. Press the button again to stop the handpiece. (Alternate

operation)

• Keep pressing ON/OFF button more than a second, the motor

handpiece starts while the button is pressed. If you release the

button, it stops. (Intermittent operation)

• If the Foot Control (Option) is connected, stepping on the pedal

starts the motor handpiece. Releasing the Pedal stops it.

2) If you want to make adjustment to the rotation speed and

torque limit value, press the SPEED key and TORQUE key

respectively.

• If the SPEED key and TORQUE key are continuously held down, they are fast-forwarded.

• If both ON/OFF button and Foot Control (Option) are equipped, the one which rotation instruction is first

given has priority. For example, if you step on the Foot Control (Option) to start the motor handpiece, you

cannot stop it by the ON/OFF button.

NOTICE

ON/OFF Button

Fig. 9

Fig. 10

Forward Rotation

Load within the

Torque Limit Value

Reverse Rotation

Further Loading

beyond the preset

Torque Limit Value

Stop

If the load is kept applied,

the file will rotate in reverse.

When the load is removed,···

Fig. 11

12

(1) Program

You can change any preset values and have them memorized to your desired settings (rotation speed, torque limit

value, gear ratio and auto reverse mode).

1) Press the PROGRAM key until it turns to the program number which you want to have memorized.

2) Adjust the rotation speed, torque limit value, gear ratio and auto reverse mode by each key according to your

needs.

3) Hold down the MEMORIZE key for more than one second. When the alarm sounds, memorization is completed.

(2) Initialization of Program (Factory-set configuration)

T

he program can be returned to the original state configured at the time of factory shipment, if setup becomes

confusing.

1) Turn off the power, when the power is on.

2) Connect the AC adapter and confirm that the AC IN lamp lights up.

3) Hold down the POWER key for more than one second, while pressing the AUTO REVERSE key and MEMORIZE key

at the same time.

4) Release the keys when the LCD panel indicates “ ”, and re-press the MEMORIZE key while this is displayed.

5) Initialization is completed, when“ ” is displayed.

6. CONVENIENT FUNCTIONS

• The program cannot be memorized while the motor handpiece is in motion.

• The rotational direction is not memorized in the program. The program cannot be memorized if the rotational

direction is set to the reverse rotation (R).

• If the PROGRAM key is kept pressed, it is fast-forwarded.

• The program is not memorized unless the MEMORIZE key is held down for more than one second. If the

program number is changed by the PROGRAM key without pressing the MEMORIZE key, the initially

memorized preset values remain. (Cancel function)

NOTICE

(6) Completion of Medical Treatment

When the treatment is completed, return the motor handpiece to the handpiece stand and hold down the POWER

key for more than one second to turn off the power.

If 10 minutes pass without operation of the ON/OFF button or Foot Control (Optional), the power turns o

automatically. (Auto power o function) However, the power does not turn o automatically if the motor

handpiece is in motion, even if it is not used.

NOTICE

AUTO REVERSE OFF

The motor handpiece stops without reverse rotation. In this instance, the LCD panel shows “ ” and the

rotation speed alternately.

• When the reverse rotation (R) is set, the Auto Reverse Function is not activated.

• When the batteries go down (when the mark of the remaining amount of the batteries indicates “ , ”),

the actual load may not reach the preset torque limit value. In this case (in the case of operation by batteries),

this auto reverse function will not be activated. When high torque is required, use the AC adapter or use this

product in a condition where the batteries are not significantly consumed (when the mark of the remaining

amount of the batteries indicates “ , ”).

• If a load is continuously applied to the motor handpiece, it may automatically stop to prevent overheating. (The

torque limit value indicates “ ” on the LCD panel). In this case, leave the motor handpiece for a while until it

cools down. When the display returns to normal, the motor handpiece can be used.

NOTICE

13

(4) Calibration

This function is to decrease fluctuation in the rotation speed of the motor handpiece and the difference in torque by

the contra angle head.

1) Lubricate the contra angle head with the spray. (Refer to the “P14 7. (1) Lubricating Contra Angle Head.”)

2) Turn off the power if the power is on.

3) Connect the AC adapter and confirm that the AC IN lamp lights.

4) Turn on the power.

5) Hold down both buttons of the SPEED key simultaneously for more than one second.

6) The LCD panel displays “ ” with the alarm sound.

7) Attach the contra angle head to the motor handpiece and press the MEMORIZE key.

8) If the motor handpiece begins to rotate, leave it as it is until it stops.

9) This process ends, if the rotation stops and the LCD panel display returns to its original state.

10) If you want to stop this process, turn off the power.

(3) Battery Refresh

Nickel-metal-hydride batteries may result in a decrease in charging capacity, if additional charging (repeating a cycle

of short-time use and recharging) is made. (Generally, this phenomenon is called a “memory effect.”) This Battery

Refresh function is to resolve this phenomenon.

1) Turn off the power if the power is on.

2) Connect the AC adapter and confirm that the AC IN lamp lights.

3) Hold down the POWER key for more than one second, while pressing the REVERSE key.

4) The alarm sounds for a length of time, and the refresh mode is activated. At this time, the mark of the remaining

amount of the batteries on the LCD panel is animated in the direction opposite to display at the time of charging.

At the same time, the CHARGE lamp flashes slowly.

5) Leave it as it is. The batteries are discharged and recharged automatically.

6) Hold down the POWER key for a while, when you want to stop this process. (At this time, the power does not turn on.)

• Lubricate the contra angle head before Calibration.

• This function does not operate if AC adapter is not used.

• Do not touch or apply a load to the rotating shaft of the contra angle head. It obstructs accurate measurement.

• This function cannot completely absorb the individual difference of the actual motor handpiece and contra angle head.

NOTICE

• This function is not activated unless this product is powered by the AC adapter.

• If this function is used, all programs will disappear and return to the originally set values. Record the present

program details according as needed.

NOTICE

• This function is not activated, if not driven by the AC adapter.

• It may take up to 5 hours to discharge batteries.

• It takes 5 hours to discharge and 5 hours to recharge. Therefore, total of about 10 hours are required. For

example, if dental treatment is finished at 7 p.m. and the refresh mode is set, the batteries will be fully

charged by 5 a.m. the next morning at the longest.

• This function is not required for each charging. Try this function, if the operating time is shortened even if the

batteries are relatively new.

• Do not repeat activation and deactivation of the refresh mode in a short time. It may result in enhancement of

the memory effect.

• This function is fully effective for solution of a “memory effect.” However, it cannot be solved completely at

one time due to characteristics of batteries. We recommend you repeat this process a few times according

to need.

NOTICE

Spray Nozzle

Spray Lubricant

Contra Angle Head

14

Autoclaving

1) Brush the debris off the surface of the contra angle head, and wipe it off with a cotton cloth moistened with isopropyl

alcohol. Do not use metal brush.

2) Lubricate the head with the spray lubricant.

(Refer to the “P.14 7. (1) Lubricating Contra Angle Head.”)

3) Insert the head into an autoclave pouch and seal it.

4) Autoclavable up to max. 135°C (275ºF).

ex.) Autoclave for 20 min. at 121°C (250ºF), or 15 min. at 132°C (270ºF).

5) Keep the contra angle head in the autoclave pouch to keep it clean until you use it.

* Sterilization at 121°C (250ºF) for more than 15 minutes is recommended by EN13060 or EN ISO17665-1.

• Sterilize the contra angle head only.

• For the sterilization method, we recommend the autoclave sterilization method.

• Sterilization is required first time you use and after each patient as noted below.

8. STERILIZATION

(1) Lubricating Contra Angle Head

• Lubricate the contra angle head only.

• Supply spray after each use and/or before each calibration

and autoclaving.

1) Screw the spray nozzle onto the spray nozzle.

2) Insert the spray nozzle into the rear part of the contra angle

head and lubricate the head for 2-3 seconds. (Fig. 12)

(2) Cleaning Motor Handpiece

When the motor handpiece becomes dirty, wipe it off with a cotton cloth moistened with isopropyl alcohol.

7. CLEANING

• Do not lubricate the motor section of the motor handpiece.

• To clean the motor handpiece, do not use any solvent such as benzine and, thinner.

• Before mounting the lubricated contra angle head to the motor handpiece, wipe off extra oil. Stand on its end or

lean it in the proper position for gravity draining. Mount it after excess oil has been drained.

• Hold the contra angle head securely to prevent it from flying off by the pressure of the spray.

• Supply lubricant until it comes out of the handpiece head (for approx. 2 seconds).

• Do not use a spray can upside down. In such a case, only spray gas comes out and oil is not sprayed.

CAUTION

(5) Alarm Sound Volume Control

The alarm sound volume can be controlled at the three steps of “BIG VOLUME, SMALL VOLUME and LIMITED OFF. ”

1) Keep pressing both buttons of the PROGRAM key simultaneously.

2) The alarm mark on the LCD panel changes, and the sound volume changes.

3) Release the PROGRAM key when the sound volume reaches your required level and the required sound level is set up.

• The sound level is retained, even if the power is turned off.

• If P.12 6. (2) “Initialization of Program (Factory-set configuration)” is executed, the sound is set to “BIG VOLUME.”

NOTICE

Fig. 12

ConnectorConnector

15

The motor handpiece uses rechargeable batteries. They can be recharged 300-500 times, depending on the use conditions

of the motor handpiece. If the operating time or recharging time becomes shorter or the rotation power becomes weaker,

although the “memory effect” described in “ NOTICE” is not applicable, the life of the batteries is depleted. In such a

case, ask your dealer to replace the batteries or replace them with new ones yourself. (Refer to the “ Changing Batteries.”)

When replacing them yourself, be sure to observe the following “ CAUTIONS ON CHANGING BATTERIES.” Note that

Brasseler USA shall not be held liable for any malfunction or failure resulting from your not following the

“ CAUTIONS ON CHANGING BATTERIES.”

* we recommend our genuine Brasseler USA Batteries.

Order Code : U421070

Changing Batteries

1) Turn off the power. Remove the AC adapter.

2) Remove the batteries after sliding the battery cover on the

back of the control unit in the direction of the arrow. (Fig. 13)

3) Take out the old batteries, and pull out the cord, holding it

at the connector. (Fig. 14)

4) Insert the connector of the cord of new batteries into the

connector in accordance with the polarity indication label

inside the battery chamber, and place the batteries into the

chamber with care so as not to catch the cord.

9. CHANGING BATTERIES

In case of difficult to insert the connector onto the battery, the polarity may be incorrect. Do not insert it by force.

CAUTION

Make sure to remove the AC adapter before

changing batteries. Otherwise, it may cause a

malfunction.

CAUTION

Make sure to pull out the cord by holding the connector.

Otherwise, it may cause a break in the cord.

CAUTION

• Do not open any part other than the battery cover.

• Be sure to purchase and use only the recommended batteries. Otherwise, batteries may cause damage, fluid

leakage or explode.

• Do not work with wet hands. This may cause trouble due to short-circuiting of batteries and moisture infiltrating

this product.

CAUTIONS ON CHANGING BATTERIES

Do not apply high-temperature sterilization methods such as autoclave sterilization to any part other than the contra

angle head.

CAUTION

Fig. 13

Battery CoverBattery Cover

Fig. 14

16

If the motor handpiece stops due to an abnormality such as a malfunction, overload, break or wrong use, it automatically

checks the state of the control unit and detects the cause of the abnormality and displays an error code on the LCD panel. If

an error code is displayed, turn on the power again and check whether the same error code is displayed. If the same error

code is displayed, take action by referring to the instructions provided in the “Check/Remedy” column in the following table.

10. ERROR CODE

If batteries are replaced while the AC adapter is connected, an incorrect error code may be displayed.

NOTICE

Check/RemedyCauseErrorError code

Contact Brasseler USA.

Remove load

Contact Brasseler USA.

Leave it as it is until it cools down.

Contact Brasseler USA.

Remove load

Put the batteries into the battery

chamber, or replace with new

batteries.

Contact Brasseler USA.

Use within the range of working

temperature, or replace the batteries.

Replace the motor handpiece or

contra angle head.

Replace the batteries. If the heat

generates from the new set of batteries,

malfunction of the circuit may be

suspected. Contact Brasseler

USA.

Malfunction of circuit

The motor handpiece is

locked. (at the time of the

auto reverse mode)

Malfunction of circuit

High load was continuously

applied to the motor

handpiece for a relatively long

time.

Malfunction of circuit

The motor handpiece is

locked. (at the time of startup)

The voltage of batteries is too

low (The life of batteries or not

iserted.)

The voltage of batteries is too

high. (Malfunction of circuit)

Beyond the range of working

temperature or break in the

thermistor in the battery

section.

The operating life of the motor

handpiece or contra angle

has expired.

The batteries generate

abnormal heat.

Self-Check error

Ovecurrent

Overvoltage

Overheating of motor

Error of the brake

circuit

The axle locks up

Low voltage of

batteries

High voltage of

batteries

Beyond the range of

working temperature

Beyond the upper limit

Below the lower limit

Abnormal heat

generation from

batteries

During

rotation of

the motor

handpiece

At the time

of charging

At the time

of calibration

Other

5) Close the battery cover. Make sure to charge the batteries before use.

The used nickel metal hydride batteries are recyclable, but their disposal may sometimes not be permitted by local

laws. Return them to Brasseler USA.

NOTICE

17

When trouble is found, check the following again before contacting Brasseler USA. If none of these is applicable or the trouble

is not remedied even after action has been taken, a failure of this product is suspected. Contact Brasseler USA.

<Control Unit, AC Adapter>

Problem Cause Solution

11. TROUBLESHOOTING

<Motor Handpiece>

Problem Cause Solution

The power is not turned on.

AC IN lamp does not light.

The battery charger does

not work.

(The CHARGE lamp does

not light.)

The AC adapter is not connected.

The plug of the AC adapter is not inserted

into the outlet, or there is no electricity in the

outlet.

The batteries are empty.

No batteries are inserted.

The fuse has burnt.

The AC adapter is not connected.

The plug of the AC adapter is not inserted

into the outlet, or there is no electricity in the

outlet.

The fuse has burnt.

The AC adapter’s fuse has burnt.

No batteries are inserted.

The batteries are fully charged or in a state

near full charge.

The temperature of batteries is low.

The temperature of batteries is high.

An error code is displayed.

Check the connection.

Check the connection.

Charge the batteries or use the AC adapter.

Insert batteries, or use the AC adapter.

Contact Brasseler USA.

Check the connection.

Check the connection.

Contact Brasseler USA.

Contact Brasseler USA.

Insert batteries.

No problem

If the temperature of batteries is less than

0°C (32°F), the batteries are not

rechargeable. Charge the batteries in a warm

room. (Be careful about moisture

condensation.)

It is normal that the batteries become a little

bit warm right after charging. If the batteries

are hot under normal operating conditions,

not right after charging, there may be an

abnormality. Contact Brasseler USA.

Refer to P.16 10. ERROR CODE.

The motor handpiece does

not rotate.

The motor handpiece does

not rotate. (The error code

“ ” is displayed.)

The motor handpiece cord is not connected.

The Foot Control (Option) is not connected.

There is a break in the motor handpiece or

the motor handpiece cord.

The contra angle head is clogged.

There is a short circuit inside the motor

handpiece or the motor handpiece cord.

Check the connection.

Check the connection.

Contact Brasseler USA.

Clean or replace the contra angle head.

Contact Brasseler USA.

18

Problem Cause Solution

The motor handpiece does

not rotate. (“ ” and

the rotation speed are

displayed alternately.)

When turning on the power,

the alarm sounds, and the

motor handpiece does not

rotate.

The motor handpiece keeps

rotating. (The Foot Control

(Option) does not react.)

The motor handpiece keeps

rotating. (The ON/OFF

button does not react.)

The contra angle head is clogged.

There is a short circuit inside the motor

handpiece or the motor handpiece cord.

The power is turned on while pressing the

ON/OFF button.

There is a short circuit inside the ON/OFF

button.

The power is turned on while pressing the

Foot Control (Option).

There is a short circuit inside the Foot

Control. (Option)

It is rotated by the ON/OFF button.

It is rotated by the Foot Control (Option).

Clean or replace the contra angle head.

Contact Brasseler USA.

Check the ON/OFF button.

Contact Brasseler USA.

Check the Foot Control (Option).

Remove the foot control (Option), and rotate

the motor handpiece by the ON/OFF button,

or contact Brasseler USA.

Stop the rotation by the ON/OFF button.

Release your foot from the Foot Control

(Option) to stop, or pull out the plug of the

Foot Control (Option).

19

Brasseler USA warrants the handpiece against defects in manufacturing, workmanship and materials. Brasseler USA

reserves the right to analyze and determine the cause of any problem. Warranty is voided should the handpiece not be

used in accordance with this manual.

12. WARRANTY

• Please consult with Brasseler USA about waste disposal.

• The used nickel metal hydride batteries are recyclable, but their disposal may sometimes not be permitted by local laws.

Return them to Brasseler USA.

13. DISPOSING PRODUCT

Symbols

Guidance and manufacturer's declaration - electromagnetic emissions

The EndoDrive PLUS is intended for use in the electromagnetic environment specified below. The customer or the user of the EndoDrive PLUS should assure that

is used in such an environment.

Emissions test Compliance Electromagnetic environment - guidance

RF emissions

CISPR11

RF emissions

CISPR11

Harmonic emissions

IEC61000-3-2

Voltage fluctuations/flicker emissions

IEC61000-3-3

Group 1

Class B

Class A

Complies

The EndoDrive PLUS uses RF energy only for its internal function. Therefore, its RF emissions are

very low and are not likely to cause any interference in nearby electronic equipment.

The EndoDrive PLUS is suitable for use in all establishments, including domestic establishments

and those directly connected to the public low-voltage power supply network that supply

network that supplies buildings used for domestic purposes.

TUV Rhineland of North America is a Nationally Recognized Testing Laboratory (NRTL) in the United States and is accredited

by the Standards Council of Canada to certify electro-medical products with Canadian National Standards.

Follow the waste of electric and electronic equipment (WEEE) Directive (2002/96/CE) to dispose of the product and accessories.

Consult operation instructions.

This conforms to CE European Directive of “Medical equipment directive 93/42/EEC.”

Protected against vertically falling water drops.

Manufacturer.

Type B conforming component Authorised representative in the European community.

Marking on the outside of Equipment or Equipment parts that include RF transmitters or that apply RF electromagnetic energy

for diagnosis or treatment.

Autoclavable up to Max.135°C. *for detail see Sterilization.

Class II equipment.

Short-circuit-proof safety isolating transformer. For indoor use only.

To identify fuse boxes or their location. This product meets UL safety standard requirements.

This mark is machine tool, electrical equipment and medical equipment Safety mark in Canada.

Table of contents

Other BRASSELER USA Dental Equipment manuals

BRASSELER USA

BRASSELER USA EndoSequence II User manual

BRASSELER USA

BRASSELER USA NL4500 User manual

BRASSELER USA

BRASSELER USA NL Series User manual

BRASSELER USA

BRASSELER USA HygienePro Air User manual

BRASSELER USA

BRASSELER USA PAL User manual

BRASSELER USA

BRASSELER USA EndoSync PLUS User guide

BRASSELER USA

BRASSELER USA enLITE User manual

BRASSELER USA

BRASSELER USA EndoSync TR-CM BSL User manual

BRASSELER USA

BRASSELER USA BRIO 550 User manual

BRASSELER USA

BRASSELER USA Brasseler Mini User manual