JM 2880 PD Pantographic Instructions Manual

4

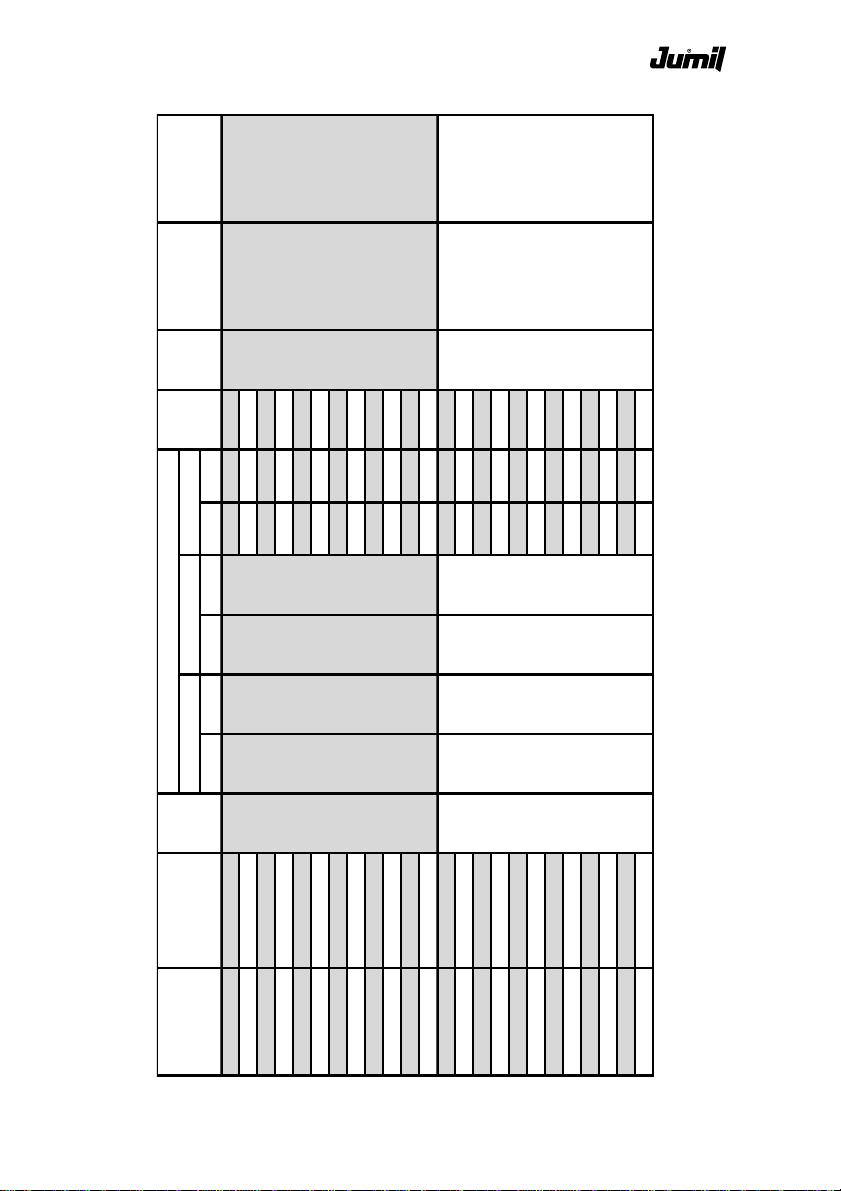

TABLE OF CONTENTS

1 - PRODUCT PRESENTATION............................................................................... 6

2 - SAFETY NORMS ................................................................................................ 7

3 - TECHNICAL SPECIFICATIONS ........................................................................ 9

3.1 - WORK POWER ..................................................................................................11

4 - OPTIONAL 8 - 10 - 12 LINES......................................................................... 14

4.1 - TABLE OF DISKS AND SHIMS ....................................................................... 16

5 - PRODUCT COMPOSITION ............................................................................. 17

5.1 - CHASSIS .......................................................................................................... 18

5.2 -HEADER ............................................................................................................ 18

5.3 -WHEELS............................................................................................................ 18

5.4 - LINE MARKERS ............................................................................................... 19

5.5 - PLATFORMS .................................................................................................... 19

5.6 - FERTILIZER COVERING KIT. .......................................................................... 20

5.7 - CONCAVE COMPACTER FOR COTTON PLANTATION............................... 23

5.8 - CONCAVE COMPACTER KIT ......................................................................... 23

5.9 -SEEDERDOUBLEDISK .................................................................................... 23

5.11 - SWEEPING KIT (OPTIONAL) ......................................................................... 24

5.10 - HYDRAULIC CYLINDER STROKE ADJUSTMENT SHIM. ............................. 24

6 - ACCOMPANYING COMPONENTS ................................................................. 25

7 - PRODUCT ASSEMBLY .................................................................................... 27

7.1 - PUTTING THEHEADER INWORKING POSITION .......................................... 27

7.2 - LONGSEEDER UNITS ...................................................................................... 27

7.3 - COMPACTER WHEELS. .................................................................................. 29

7.4 - FERTILIZER UNIT. ............................................................................................ 29

7.5 - 20" CUTTING DISK KIT (OPTIONAL). ........................................................... 31

7.6 - FERTILIZER COVERER KIT (OPTIONAL). ..................................................... 31

7.6.1 - DOUBLE DISK................................................................................................... 31

7.6.2 -FURROWER ...................................................................................................... 32

7.7 - FERTILIZER UNITS .......................................................................................... 32

7.8 - INSTALLINGTHE TIGHTENING WHEEL ........................................................ 33

7.9 - CONCAVE COMPACTER INSTALLING ......................................................... 33

8 - PREPARATIONFOR USE ................................................................................. 34

8.1 - COUPLING THE MACHINE TO THE TRACTOR ............................................ 34

8.2 - DIRECT OR CONVENTIONAL PLANTING ..................................................... 35

8.3 - DIRECT PLANTING CUTTING DISK ............................................................... 36

8.4 - FERTILIZER APPLICATORS........................................................................... 36

8.4.1 - FERTILIZER MISMATCHED DOUBLE DISK ................................................... 36

8.4.2 -RETRACTABLEDEEPFURROWER................................................................. 37

8.5 - FERTILIZER DEPTH ADJUSTMENT ............................................................... 37

8.6 - SEEDDISTRIBUTIONDEPTHREGULATION .................................................. 38

8.6.1 - DOUBLESPRINGRODS .................................................................................. 38

8.6.2 - SEEDDEPTH CONTROL.................................................................................. 39

8.6.3 - POSITIONING OFTHE DEPTH CONTROLLER WHEELS .............................. 40

8.6.4 - COMPACTING AND COVERING OF SEEDS .................................................. 42

8.7 - RATCHET ADJUSTMENT ............................................................................... 43

8.8 - GEAR ................................................................................................................ 44

8.8.1 - CHAIN TENSION ADJUSTMENT .................................................................... 45

8.8.2 -SEEDDISTRIBUTION GEAR ............................................................................ 45

8.8.3 - FERTILIZER DISTRIBUTION GEAR................................................................. 45