TABLE

OF

CONTENTS

Introductory

Pages

Regulatory

Information

and

Important

NoteS

...

eee

ee

aa

ed

Table

of

ContentS..

1...

0...

0c

3

Product

Overview

and

Technical

Specifications...........0

00

cee

eee

eee

4

Tools,

Torque

Specifications,

and

Hardware

Notes

........

0000

eee

eu

newness

5

Pre-Installation

Site

Review

and

Preparation

..........

ee

ee

ee

6

Rail

MeasurementS..

0...

0.

cc

ee

ee

ee

ee

ee

6

Rail

Cutting

Guidelines

..

0...

0...

es

eee

eee

7

Rail

Support

(Rail

Mount)

Requirements

..........000

cece

eee eee

eee

ene

7

Lower

Rail

Preparation

...........0000:

eee

eae

ee

8-9

Joint

Preparation

..

0.0...

ee

eee

ee

eee

eee

9

Upper

Rail

Preparation

............+.

dae

Dee

eee

eee

wanes.

10

Finish

Preparation

..

0.0...

ccc

ee

eee eee

en

eens

11-13

Installation

| | |

Rail

Installation...

.

0...

cee

ee

eee

eee

..

14-20

'

Non-Folding

Rail

Installations

.......0.

0.0000

eee

ee

ee

ees

wee.

14-15

_

Folding

Rail

Installations

........ 0.000000

cee

ee

eee

ee

16-20

Carriage

Installation.

........

Be

ee

21-22

Completing

Rail

Installation..............

eee

eee

ee

ee

eas

23

Footrest

Installation...

0...

ee

eee

eee

e

teen

eee

24

Seat

Installation.......

ee

ee

eee

eee

25-26

Rail

Cross

Pin

Installation

............0.

ee

eee

ee

eee

27-28

Make

Charger

Connections

......

0.0000.

cee

eee

eee

ee

ee

ee

ee

28

Lubricate

Gear

Rack............

wee

ae

eee

eee

eee

eee

eee

eens

29

Battery

Charger

Installation

.......

0.00

eee

ee

ee

es

29

Fit

&

Finish

.....

Se

ee

eee

eee

ee

eee

ee

ees

30

Customer

Education...............

ee

31-32

Electrical

|

Reprogramming

Remote

Transmitters.

.......0

00000

eee

eee

ee

ee

ee

ee

es

33

_

Single-User

vs.

Multi-User

Diagnostic

Mode.

.......

0.0...

00

0

eee

eee

34-35

Diagnostic

Codes............

ete

ees

36-37

Battery

Charger

LED

Information................

eee

eee

38

Post-Installation

Adjustment

|

Drive

Adjustment.

...

0.0...

000

ccc

eee

eee

eee

eee

eee

eee

enn

es

39

Moving

Up/Down

Paddle

Control

from

One

Arm

to

Another

............

40-44

Switch

Actuator

Rocker

Installation

Instructions

...............

ee

45

Troubleshooting

Folding

Rail

Gear

Rack

Replacement..............0000.5

ee

ee

47

Folding

Rail

Joint

Adjustment.

2...

0.

ce

eee

48-49

Apply

Grease

to

Folding

Rail

Assembly

.........

00.

eee

eee

ee

eee

ee

es

50

Power

Folding

Rail

Drive

Adjustment

......

eee

Lee

ee

eee

50

Overspeed

2...

ee

ee

Si

Maintenance

| | |

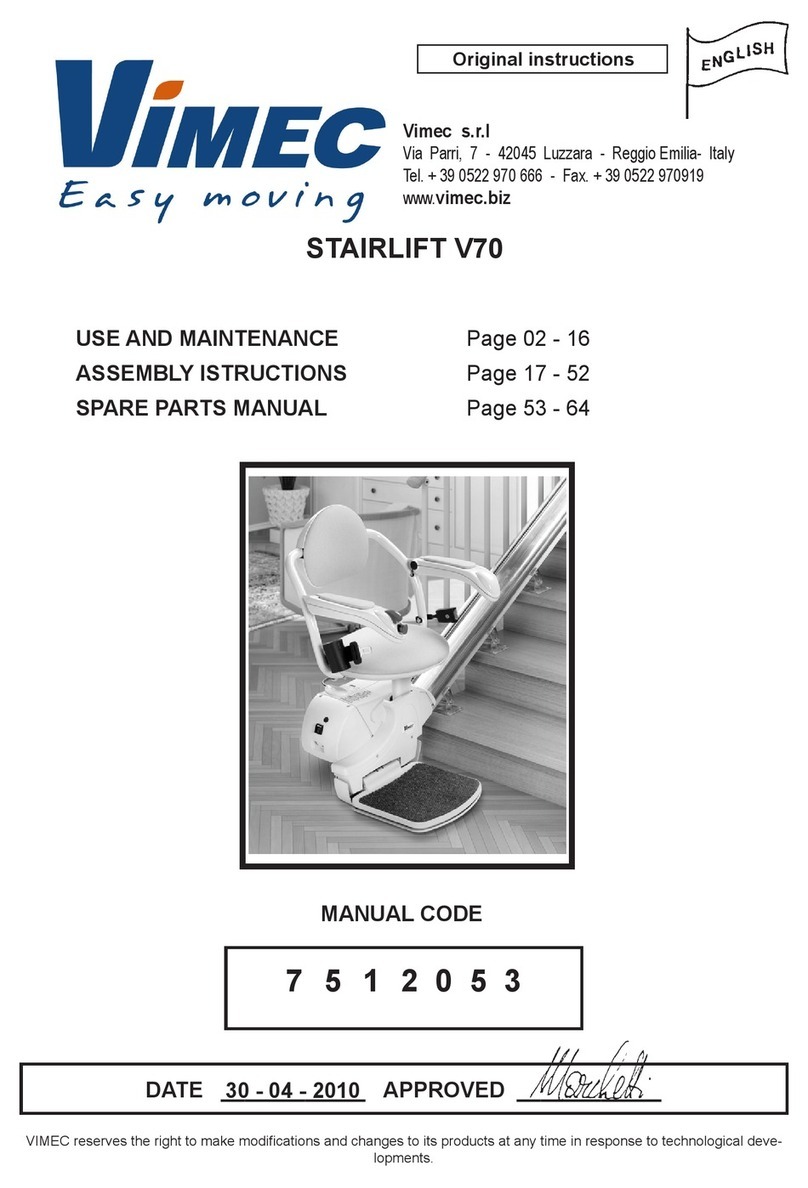

Stairlift

Maintenance

Checklist.

Ce

ee

as

52

Limited

Warranty...

1.0.0...

ee

ees

53

Wiring

Schematics.........

ee ee

es

54-55

Exploded

Views

..........

0.000

u

ene

eneeae

ee

ee

ee

ee

ee

as

56

SRE-3050

INSTALLATION

15mar2021

3

©Bruno

Independent

Living

Aids,

Inc.®