Air Pressure

Breathing air pressure must be continually monitored at the point-

of-attachment while operating the respirator. A reliable air

pressure gauge must be present to monitor the pressure during

respirator operation.

Make certain that your breathing air compressor has

sufficient capacity to deliver a minimum of 30 cfm per

respirator wearer at all times. Because Dual-Cool has

two cool tubes, it requires a higher than normal volume

of air.

The Breathing Air Pressure Table on the next page defines the air

pressure ranges necessary to provide the PC90 Series respirators

with a volume of air that falls within the required range of 6-15

cubic feet per minute (cfm) or 170-425 liters per minute (lpm). (See

42 CFR, Part 84, Subpart J, 84.150). To use the table, follow the

steps identified below:

1. Confirm the air source, respirator model, breathing tube, and

Dual-Cool tube assembly (Columns 1-4).

2. Confirm your choice of NIOSH approved Bullard air supply

hose(s) (Column 5).

3. Determine that your air supply hose does not exceed the

maximum approved hose length (Column 6) or number of hose

sections (Column 7).

4. Set the air pressure at the point-of-attachment within the

required pressure range (Column 8) for your air supply hose

length.

WARNING

Failure to supply the minimum required pressure at the point-of-

attachment for your hose length and type will reduce airflow

and could result in death or serious injury.

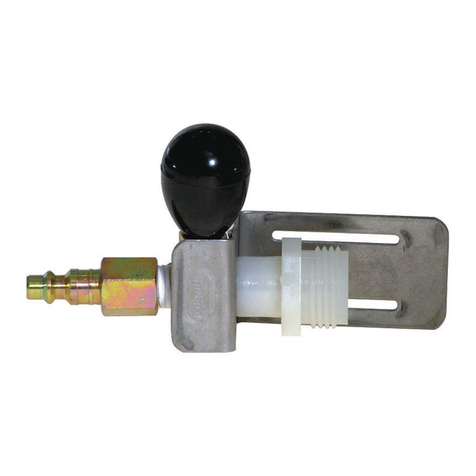

Air Supply Hose

To maintain your Bullard respirator’s NIOSH approval, use only

approved Bullard V10 Series hose(s) in lengths of 50 to 300 feet,

or Bullard V5 Series hose in lengths of 25 to 50 feet. Bullard V11

hose-to-hose adapters MUST be used to connect V10 hose lengths

together. Secure connection(s) until wrench tight and leak free.

NOTE

Do not use a quick-disconnect fitting to connect a V10

hose to the air source.This would restrict airflow and

is not approved in this configuration.

WARNING

Use of any other air supply hose voids NIOSH approval of the

entire respirator assembly and might reduce the airflow to the

respirator, which could result in death or serious injury to the

respirator wearer.

WARNING

The DC60 Dual-Cool climate control system is not recommended

for cooling the air supply when the air temperature is less than

70°F. Because the DC60 Dual-Cool may cool the incoming air by

more than 30°F, it is possible for ice to form in the breathing

tube and reduce the airflow. Failure to observe these warnings

could result in death or serious injury.

Compressed air must be dry enough to prevent ice buildup in the cold

airstream. Ice could reduce airflow into the respirator hood.

Replacement Parts

CATALOG

NUMBER DESCRIPTION

DC65ML Medium/Large Cooling Vest

DC65XLXXL X-Large/XX-Large Cooling Vest

CH60 DC50 Series Dual-Cool Connector Hose

4612 Nylon Belt

Breathing Air Pressure Table

This table defines the air pressure ranges necessary to provide the PC90 respirator with a volume of Grade D breathable air that falls within the U.S. Government

required range of 6-15 cfm (or 170-425 lpm). See 42 CFR, Part 84, Subpart J, 84.150.

(1) (2) (3) (4) (5) (6) (7) (8)

Maximum Air Maximum Required

Supply Hose Number Pressure

Breathing Dual-Cool Air Supply Length of Hose Range

Air Source Respirator Tube Tube Assembly Hose (feet) Sections (psig air)

Stationary PC90 90BT DC6040 1/4" Ind. Int., steel 50 2 48-52

or portable DC604B 1/4" Ind. Int., brass 100 3 59-63

compressor 90BTF DC6040S 1/4" Ind. Int., stainless V10 150 3 68-72

supplying DC6041 1/4" Schrader 200 3 80-84

Grade D 90ELF DC6042 1/4" Snap-Tite, steel 250 3 85-92

breathing DC6043 1/4" Snap-Tite, brass 300 5 90-98

air DC6044 1/4" Snap-Tite, stainless V5 25 1 53-57

DC6047 1/4" Cejn, steel 50 2 67-71