5

Procedure for eld installation of insulation

on union models

1. Remove the protective stip from the adhesive

surface. Re-close the insulation shells.

2. If the hydraulic separator is used with chilled

water spread a thin layer of sealant on the edge of

the insulation and wait until the solvent evaporates

(approximarly 10 minutes) and close it again. Note

that once the sealant dries it may be difficult to

remove the insulation shell in the future without

destroying portions of the insulation.

3. Reassemble the two side sections.

Service Instructions

There is no service required for the hydraulic separator.

CAUTION:

Corrosionorleakage cancause damage or injury.

Periodically inspect for signs of corrosion or leakage. If corrosion or

leakage is note,the vent must be replaced. Failure to follow these

instructions could result in property damage and/or personal injury.

B

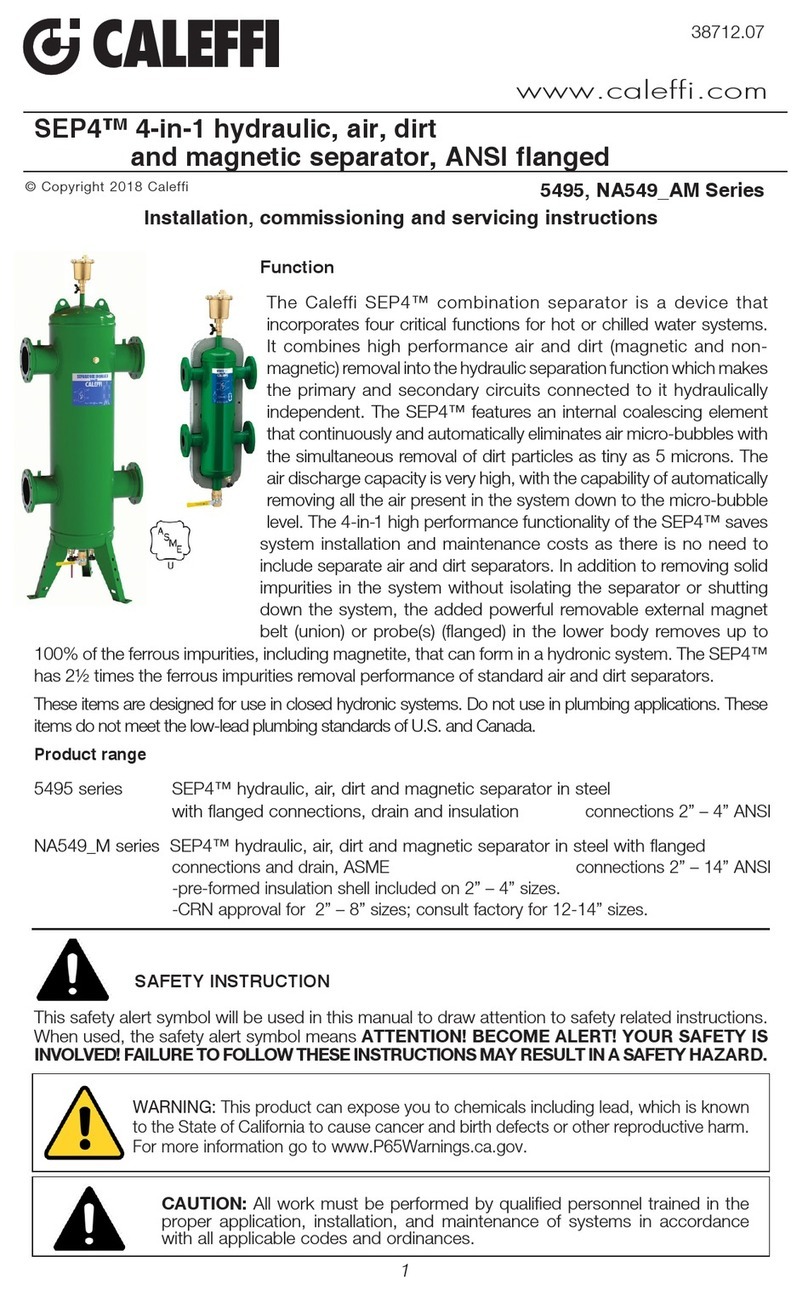

Procedure for installation and insulation assembly

(only for 2” to 4” sizes)

1. Remove the two black head covers at the ends.

2. Open the two side sections and the lower cap.

3. Install the separator in the system.

4. Spreadathin layer of sealant over surfacesAand B.

Wait for the solvent to evaporate (approx. 10 minutes).

5. Reassemble the two side sections, tting the lower cap into

one of the two sections and then connecting the other.

6. Finish the assembly with the adhesive tape provided in the box.

7. Complete with the two black head covers.

8. Fit the automatic air vent and the drain valve.

Procedure for installation and insulation

assembly on union models

1.

Remove the protective strip from the adhesive

surface. Re-close the insulation shells.

2. If the hydraulic separator is used with chilled

water spreadathin layer of sealant on the edge

of the insulationandwait until the solvent

evaporates (10 minutes approx

)

and the close

it again.

A

Caleffi North America, Inc.

3883 West Milwaukee Road

Milwaukee, WI 53208

T: 414.238.2360 F: 414.238.2366

-18

Service Instructions

There is no service required for the hydraulic separator.

CAUTION:

Corrosionorleakage cancause damage or injury.

Periodically inspect for signs of corrosion or leakage. If corrosion or

leakage is note,the vent must be replaced. Failure to follow these

instructions could result in property damage and/or personal injury.

B

Procedure for installation and insulation assembly

(only for 2” to 4” sizes)

1. Remove the two black head covers at the ends.

2. Open the two side sections and the lower cap.

3. Install the separator in the system.

4. Spreadathin layer of sealant over surfacesAand B.

Wait for the solvent to evaporate (approx. 10 minutes).

5. Reassemble the two side sections, tting the lower cap into

one of the two sections and then connecting the other.

6. Finish the assembly with the adhesive tape provided in the box.

7. Complete with the two black head covers.

8. Fit the automatic air vent and the drain valve.

Procedure for installation and insulation

assembly on union models

1.

Remove the protective strip from the adhesive

surface. Re-close the insulation shells.

2. If the hydraulic separator is used with chilled

water spreadathin layer of sealant on the edge

of the insulationandwait until the solvent

evaporates (10 minutes approx

)

and the close

it again.

A

Caleffi North America, Inc.

3883 West Milwaukee Road

Milwaukee, WI 53208

T: 414.238.2360 F: 414.238.2366

-18

Procedure for installation of insulation for

2" to 4" anged models

1. Remove the two black head covers at the ends.

2. Open the two side sections and the lower cap.

3. Install the separator in the system.

4. Spread a thin layer of sealant over surfaces A

and B. Wait for the solvent to evaporate (approxi-

mately 10 minutes).

5. Reassemble the two side sections, fitting the

lower cap into one of the two sections and then

connecting the other.

6. Finish the assembly with the adhesive tape

provided in the box.

7. Complete with the two black head covers.

8. Install the automatic air vent and the drain valve.