CALEFFI HydroLink 559921A User manual

Other CALEFFI Water Filtration System manuals

CALEFFI

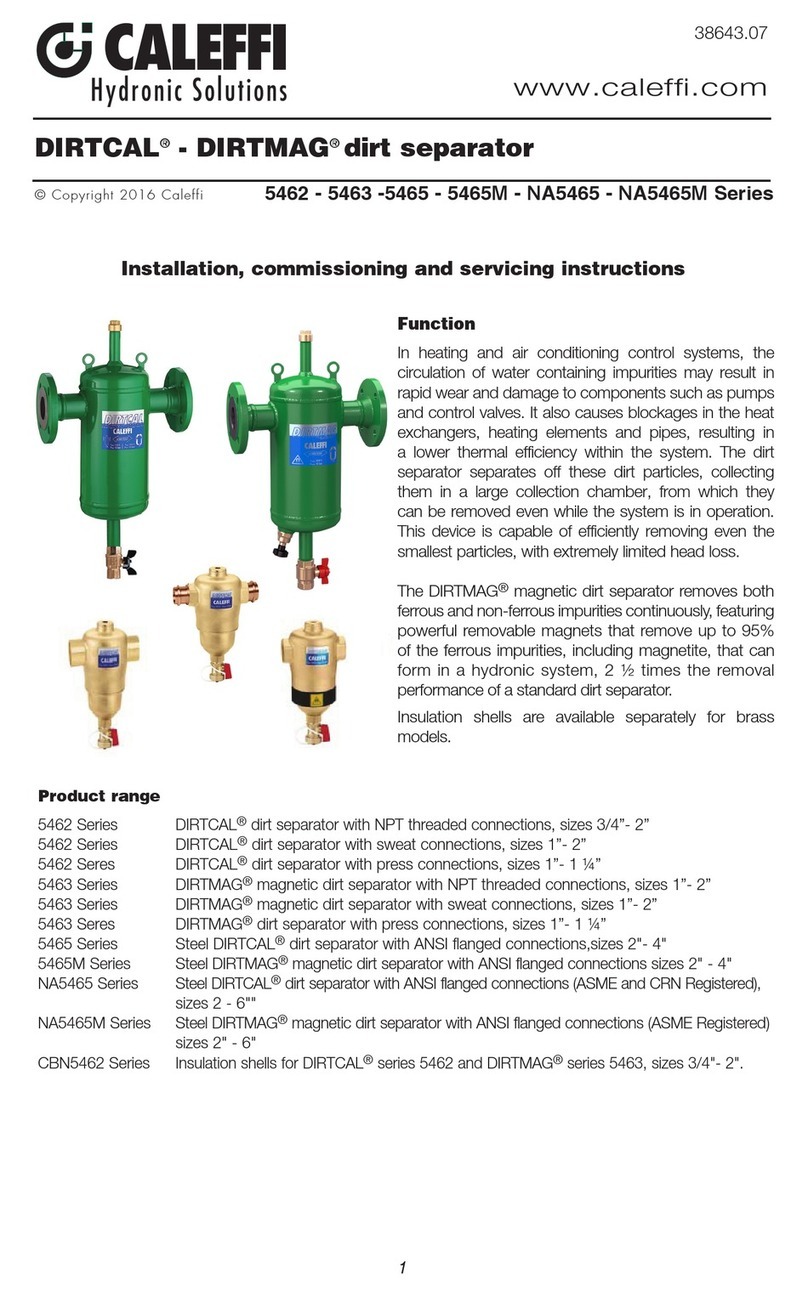

CALEFFI 546 Series User manual

CALEFFI

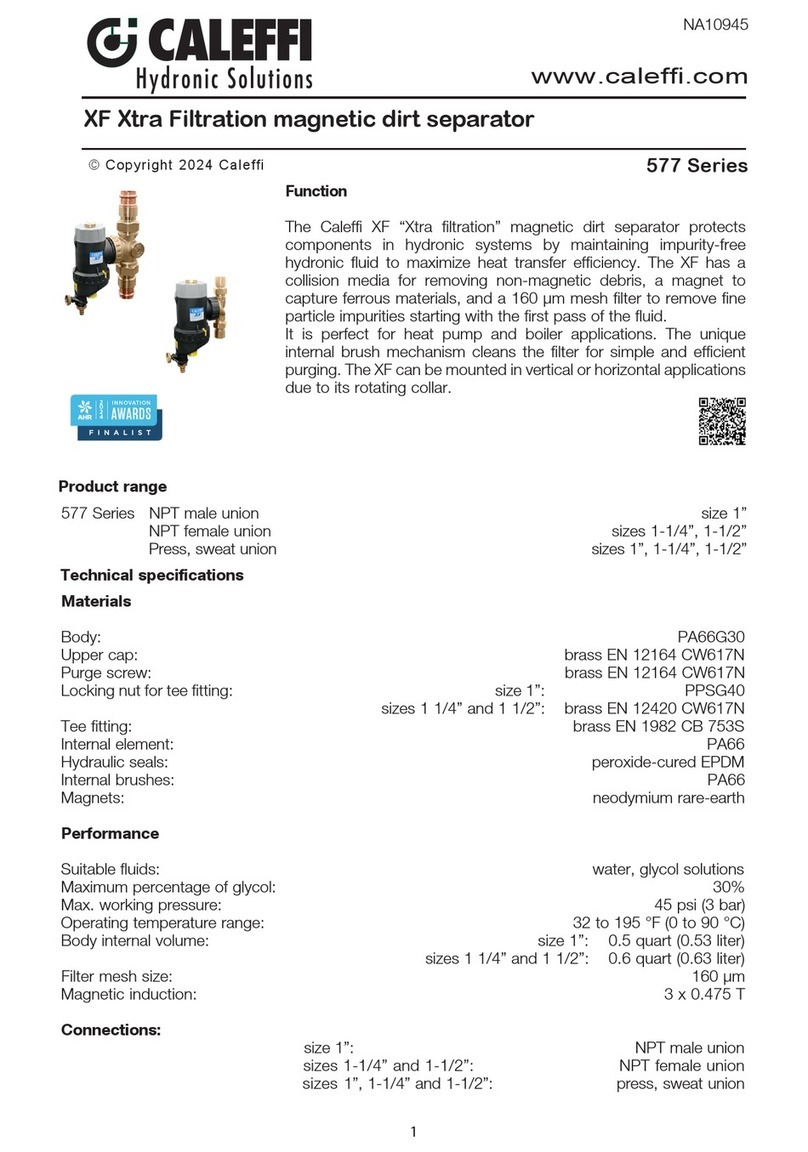

CALEFFI 577 Series User manual

CALEFFI

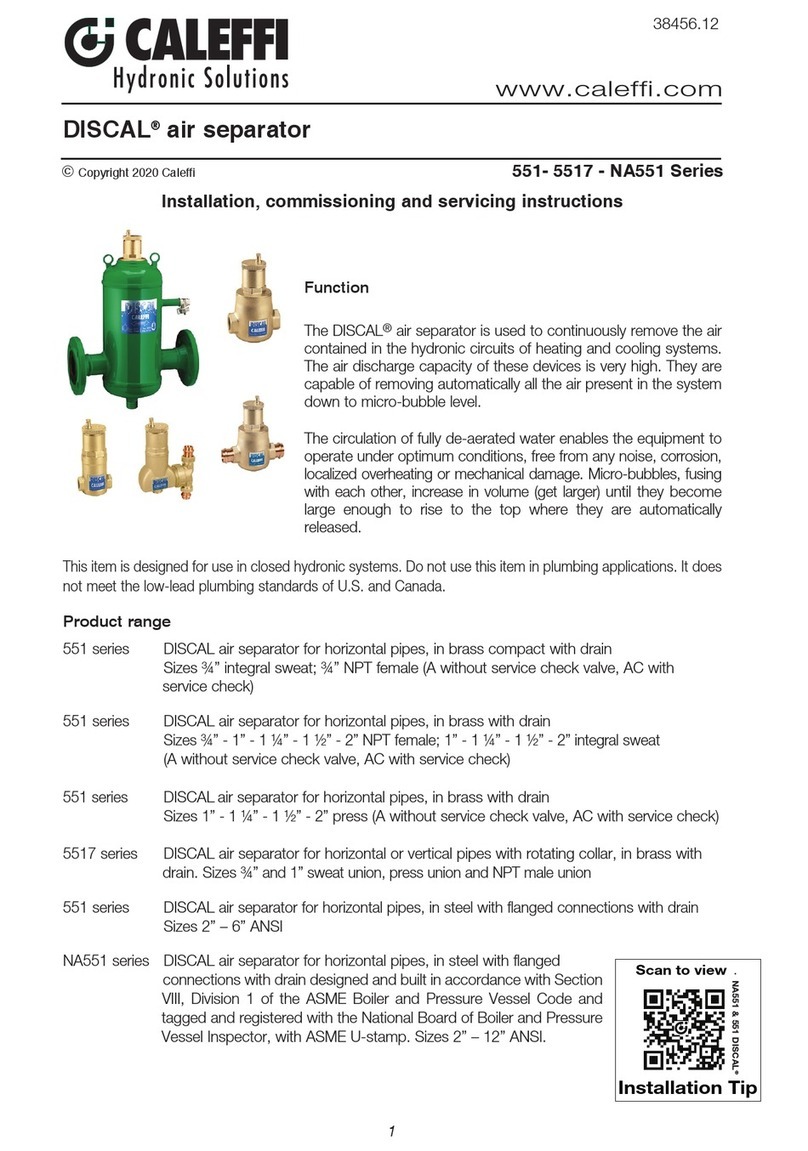

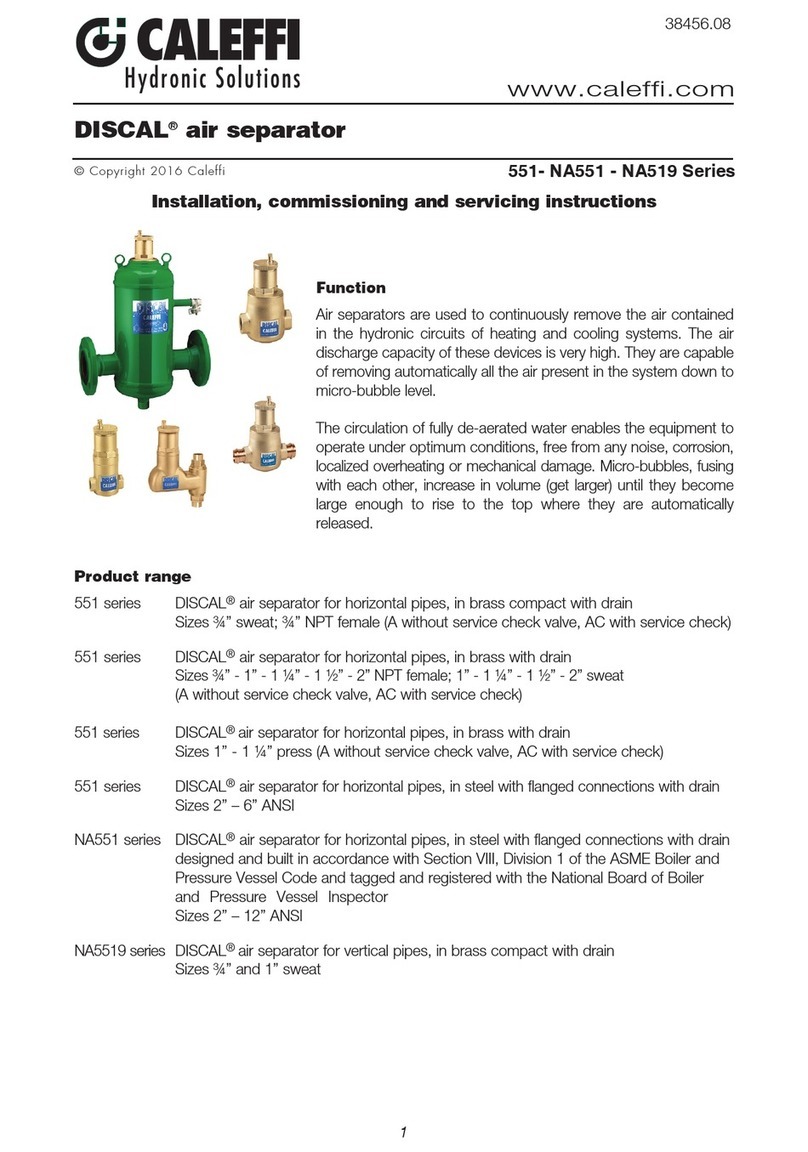

CALEFFI DISCAL NA551 Series User guide

CALEFFI

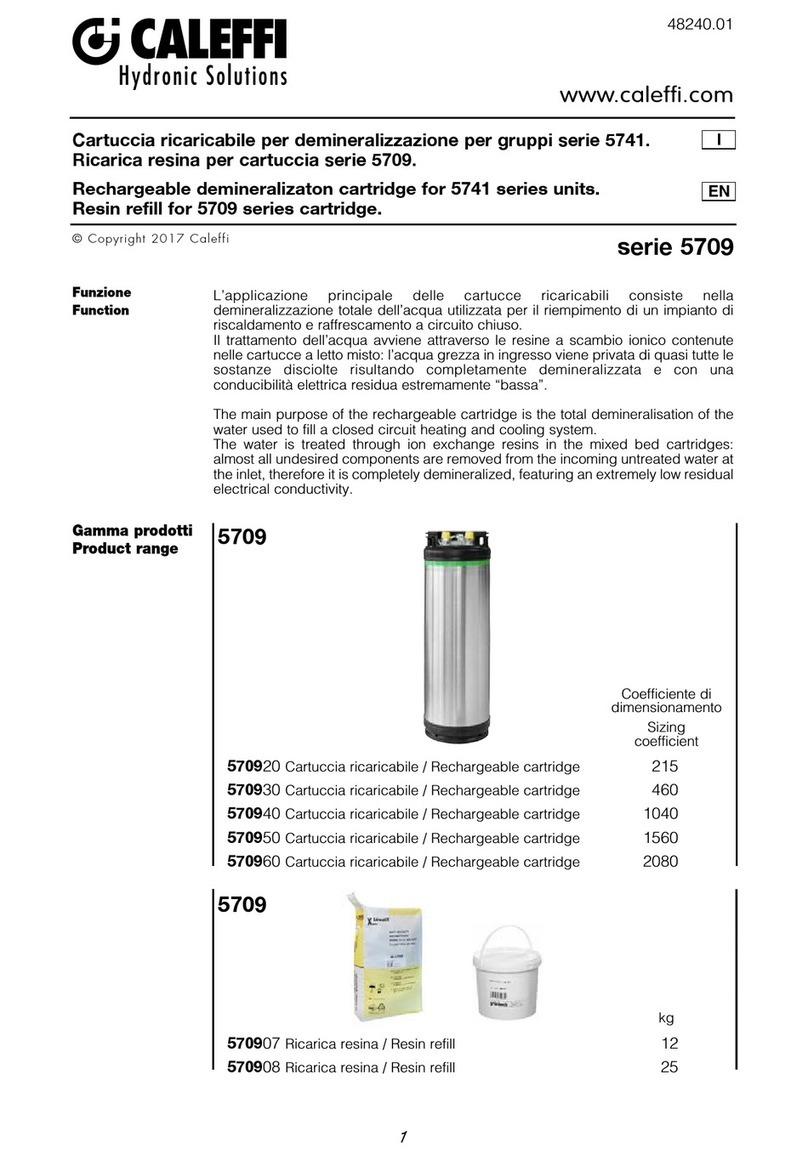

CALEFFI 5709 Series User manual

CALEFFI

CALEFFI 5370 Series User manual

CALEFFI

CALEFFI DIRTCAL 5462 Series User guide

CALEFFI

CALEFFI DIRTMAGCLEAN 579 Series Owner's manual

CALEFFI

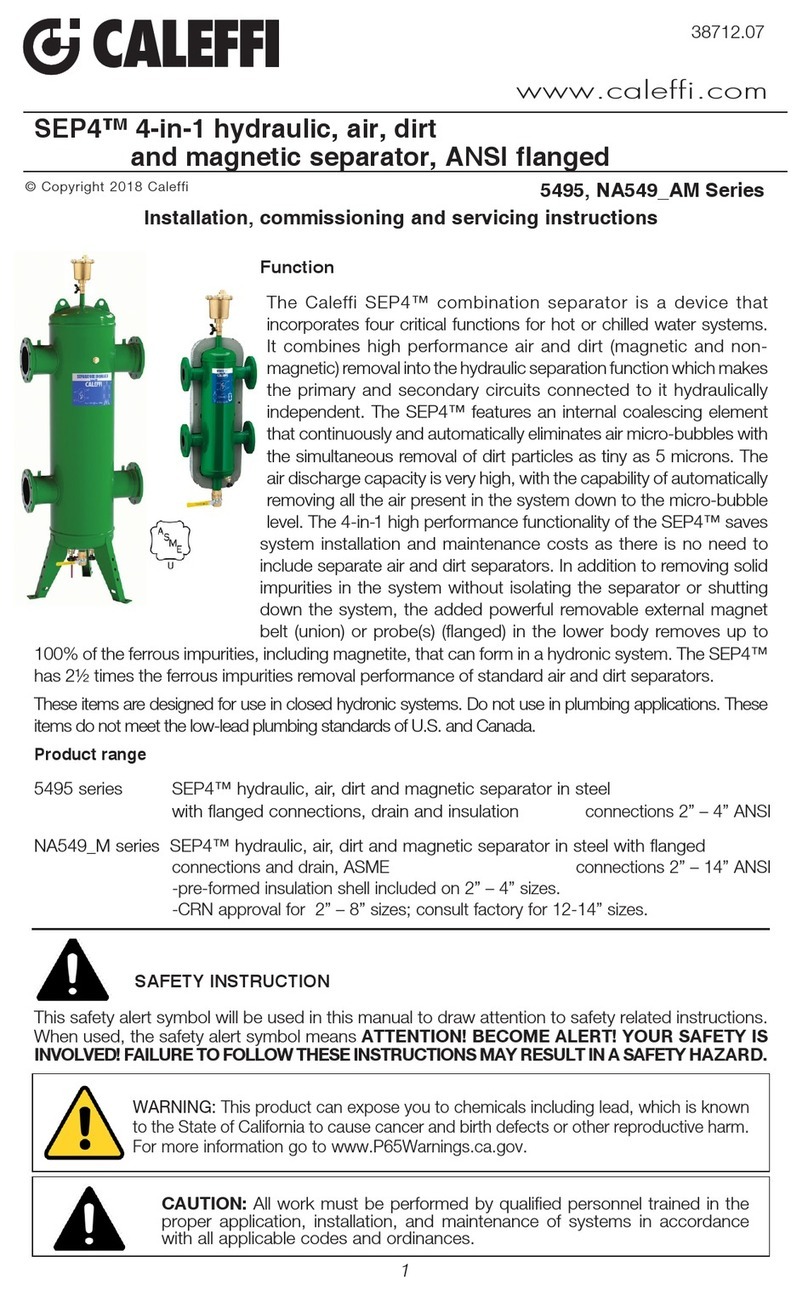

CALEFFI 5495 Series User manual

CALEFFI

CALEFFI DIRTCAL 5462 Series User manual

CALEFFI

CALEFFI 5495 SEP4 User guide

CALEFFI

CALEFFI DISCAL 5517 Series User guide

CALEFFI

CALEFFI SEPCOLL 559 Series User manual

CALEFFI

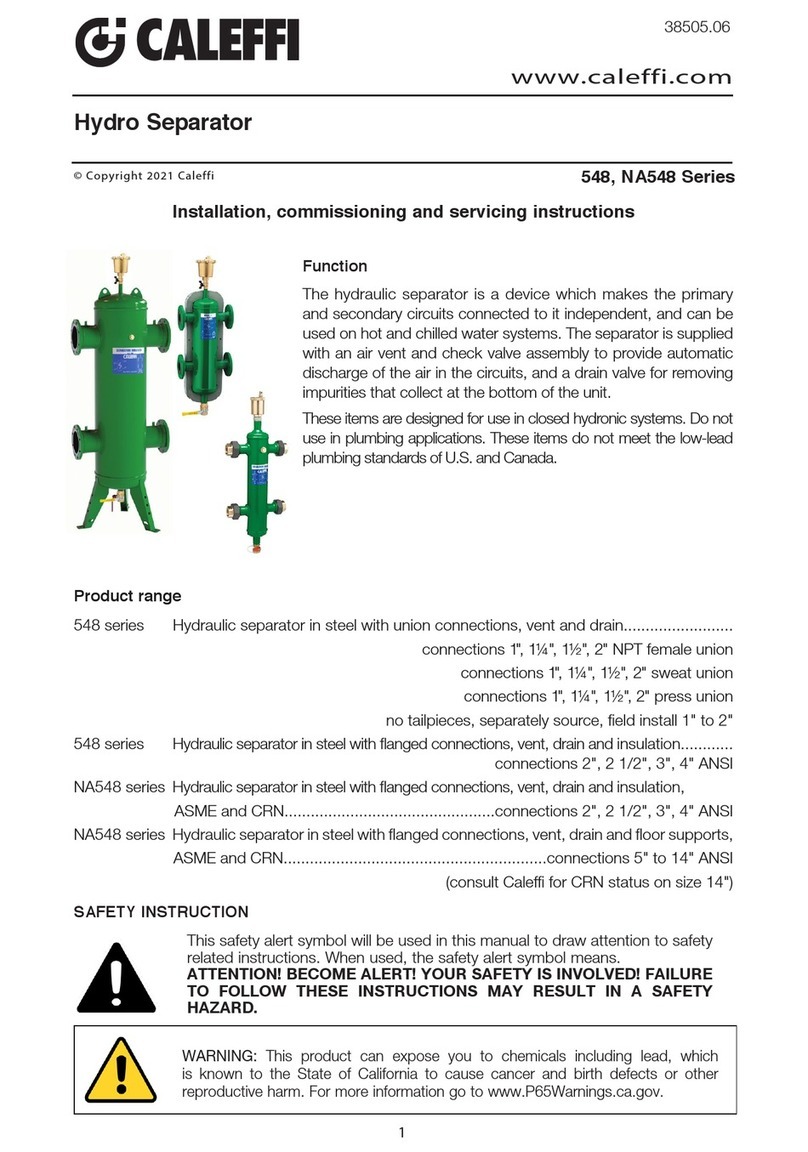

CALEFFI 548 Series User guide

CALEFFI

CALEFFI 5495 SEP4 User guide

CALEFFI

CALEFFI 5709 Series User manual

CALEFFI

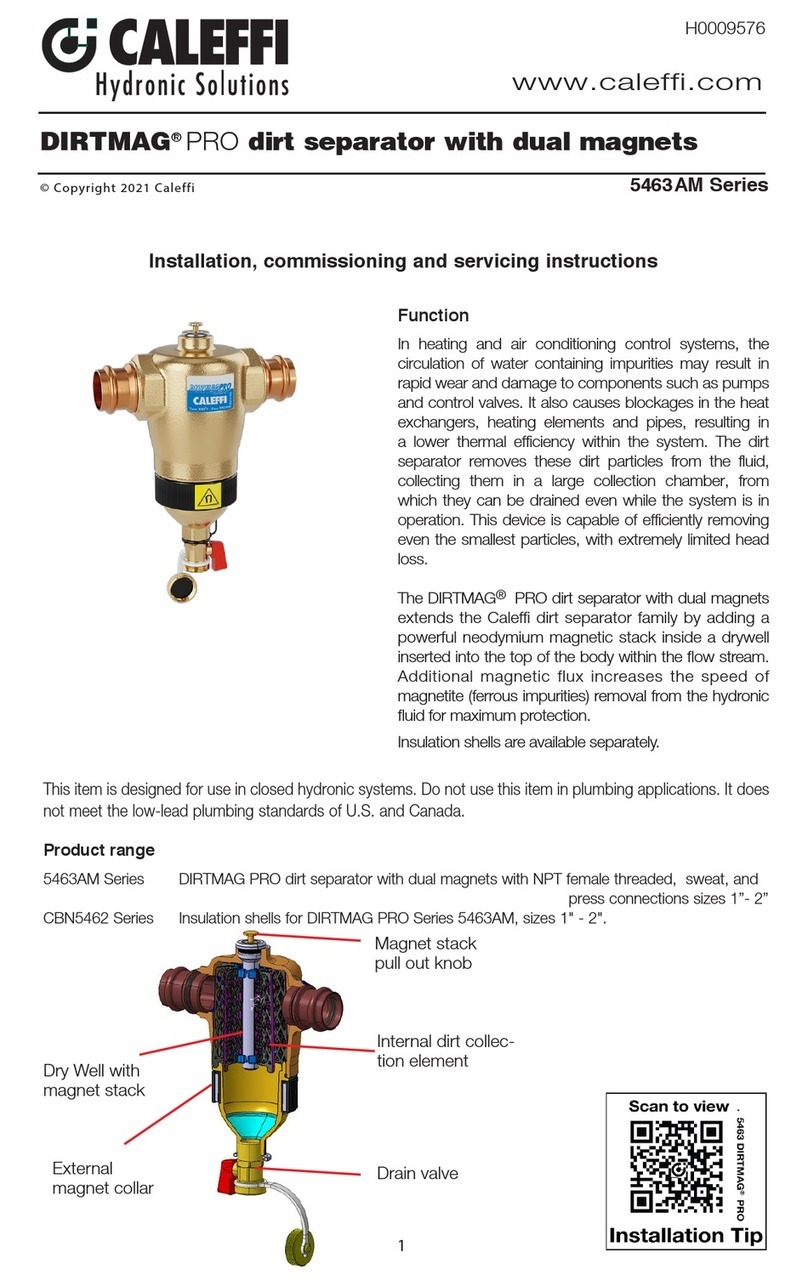

CALEFFI DIRTMAG PRO 5463AM Series User guide

CALEFFI

CALEFFI DISCAL 551 Series User guide

CALEFFI

CALEFFI DIRTMAG NA5453 Series User guide

CALEFFI

CALEFFI 580020 Owner's manual

CALEFFI

CALEFFI DIRTMAGCLEAN User manual

Popular Water Filtration System manuals by other brands

Wisy

Wisy LineAir 100 Installation and operating instructions

Schaffner

Schaffner Ecosine FN3446 Series User and installation manual

Pentair

Pentair FLECK 4600 SXT Installer manual

H2O International

H2O International H20-500 product manual

Renkforce

Renkforce 2306241 operating instructions

Neo-Pure

Neo-Pure TL3-A502 manual