Page

3 - 2 1.1.3 Carriage unit

3 - 3 1.1.4 Internal part

3 - 4 1.1.5 Roll media cassette unit

3 - 5 2. PRINTER SETUP

3 - 5 2.1 Installation

3 - 6 2.1.1 Installation environment

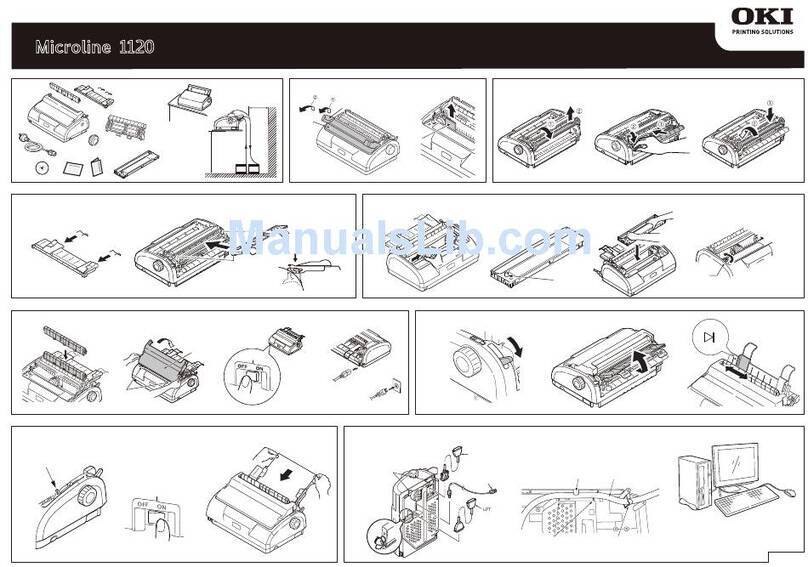

3 - 7 2.1.2 Unpacking

3 -10 2.1.3 Removing packing materials

3 -11 2.1.4 Removing the carriage fixing plate

3 -12 2.1.5 Connecting the power supply

3 -13 2.1.6 Language Setting

3 -14 2.1.7 Level adjustment

3 -17 2.1.8 Releasing the check valve

3 -19 2.1.9 Installing the ink bottles

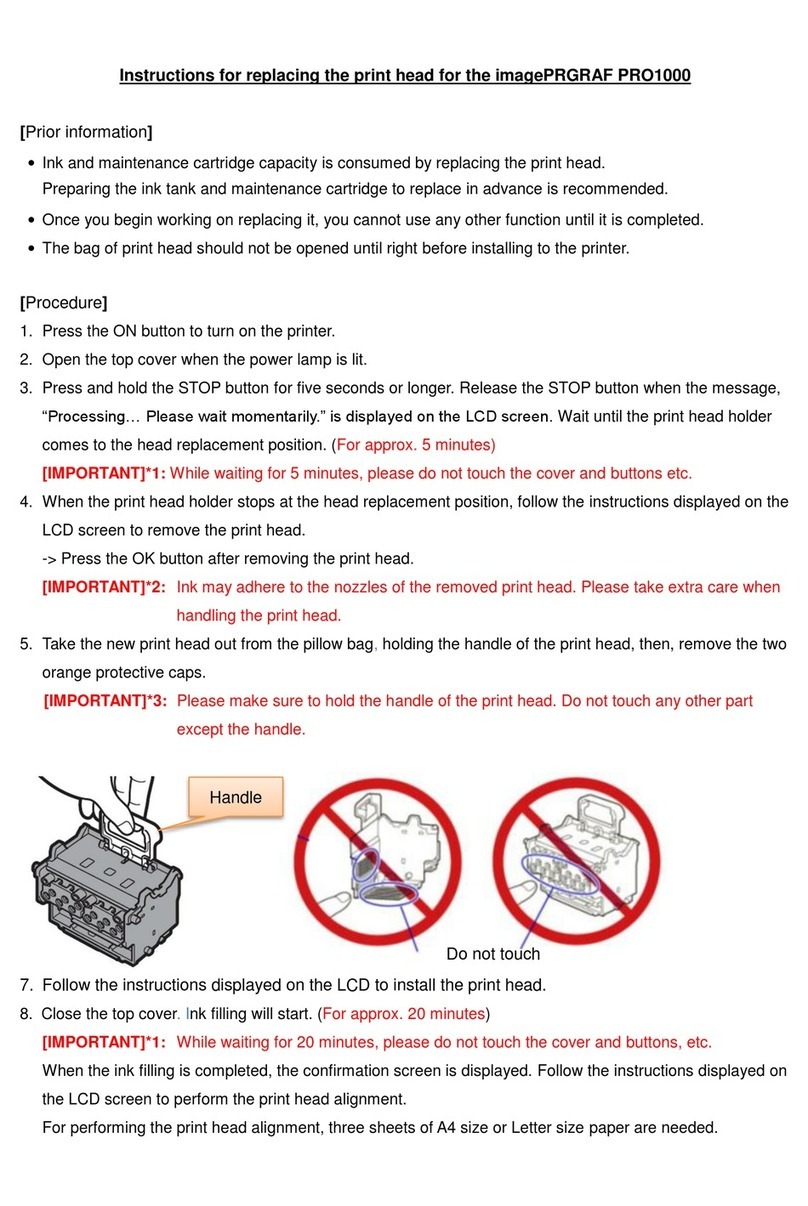

3 -20 2.1.10 Installing the BJ print heads

3 -21 2.1.11 Ink filling and date/time settings

3 -21 2.1.12 Loading paper

3 -21 2.1.13 Operation check

3 -22 2.1.14 Connecting the interface cable

3 -23 3. TRANSPORTING THE PRINTER

3 -23 3.1 Transporting the Printer

3 -24 3.1.1 Moving the printer on the same floor

3 -25 3.1.2 How to transport the printer to a different floor

3 -27 3.1.3 Manual capping

3 -28 3.2 Reinstalling the Printer

3 -28 3.2.1 Installing the printer on the same floor

3 -28 3.2.2 Installing the printer on a different floor

3 -29 4. OPERATION

3 -29 4.1 User Replacements

3 -29 4.1.1 Replacing print media

3 -29 4.1.2 When to replace roll media

3 -30 4.1.3 How to replace roll media

3 -33 4.1.4 Loading cut sheet media

3 -34 4.1.5 Replacing the BJ print head

3 -36 4.1.6 Replacing the ink bottle

3 -38 4.1.7 Replacing the waste-Ink tank

3 -40 4.2 Operation Panel

3 -42 4.3 Change of Printer Status

3 -43 4.4 User Mode

3 -43 4.4.1 User mode operations

3 -44 4.4.2 Map of the user mode

3 -46 4.4.3 Details of user mode

3 -51 5. PRINTER SERVICING FUNCTIONS

3 -51 5.1 Installation mode

3 -51 5.1.1 Installation mode operation

3 -52 5.1.2 Map of the installation mode

3 -53 5.1.3 Details of installation mode

3 -55 5.2 Service Mode

3 -55 5.2.1 Service mode operation

3 -56 5.2.2 Map of the service mode

3 -58 5.2.3 Details of service mode

3 -66 5.3 Error Indications

III