9

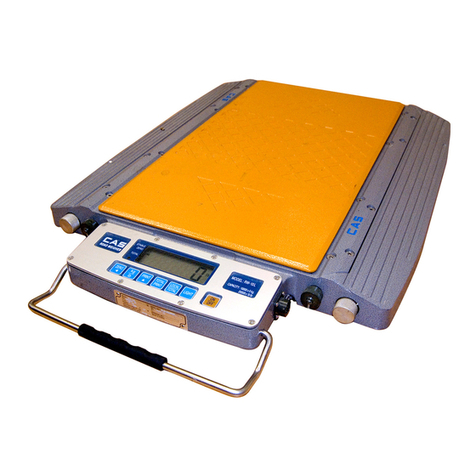

2. Key Part

Key functions in simple weighing mode & in weight comparing mode.

Used to turn ON/OFF BACK LIGHT, F03-00.

Used to print. F03-01 04.

Used to enter the SET MODE by pressing for 5 sec.

Used to return the display to the zero.

(Within 2% of Max. capacity)

Used to enter the system mode by pressing for 3 sec.

Used to weigh item by using tare.

Used to display NET weight or GROSS weight

In case tare weight is registered, tare plus item’s weight is GROSS

weight and only item’s weight is NET weight.

Used to change weight units(kg, lb, oz) to weigh the moving object.

(Auto/Manual).

Used to power ON/OFF.

Key functions in COUNT mode.

Used to display the unit weight(for approx 5 sec).

Used to display the current weight(for approx 5 sec).

Key functions in SET mode(Digit input method).

Input the digit with using the below keys.

key: Change the set value.

Increase the first place value to 1.

key: Change the digit of the set value.

Used to set current value 10.

key: Used to complete the input and move to the next mode.

Used to set the inputted value to “0”.

Used to escape from this mode.

LIGHT

PRINT

MODE

ZERO

ON

OFF

NET

GROSS

UNIT

HOLD

MODE

ZERO

LIGHT

PRINT

TARE

U.W.

W.