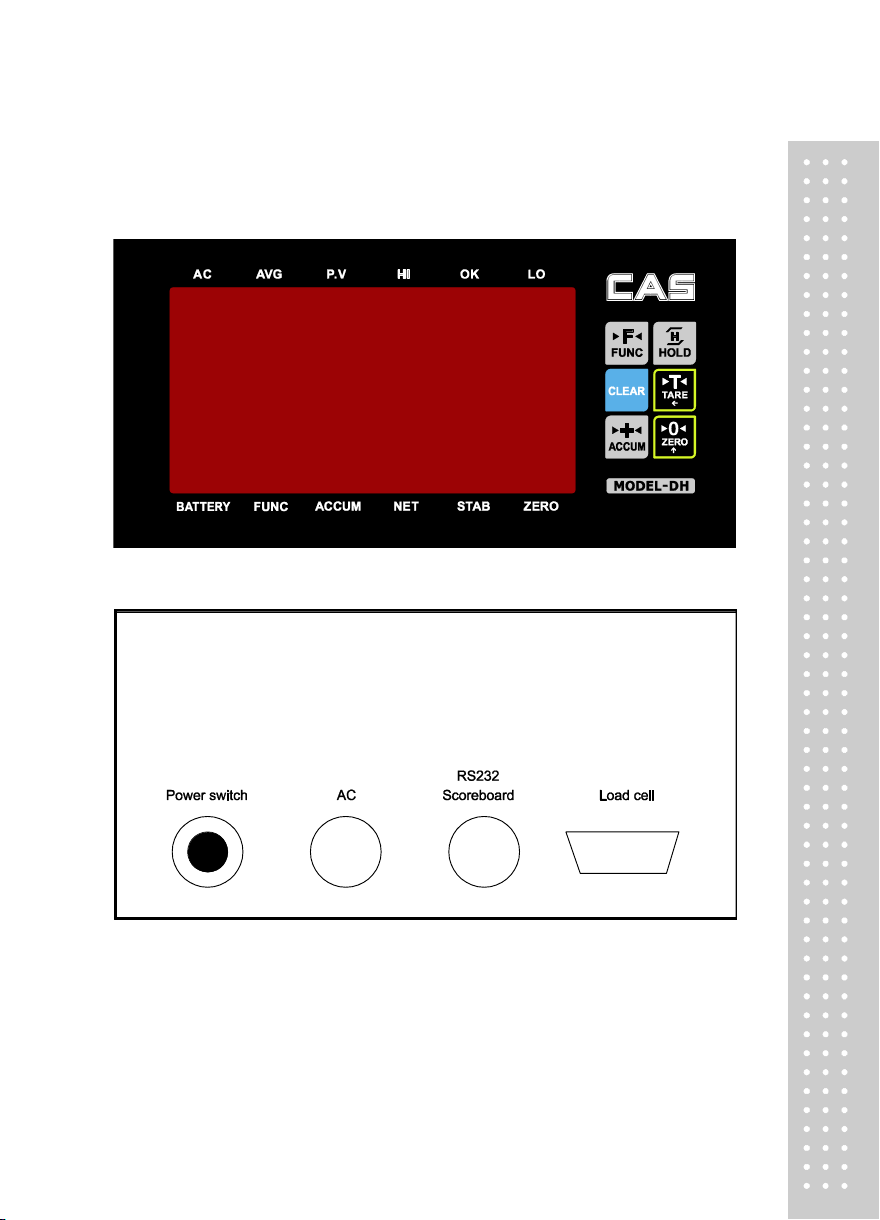

Operation Instruction

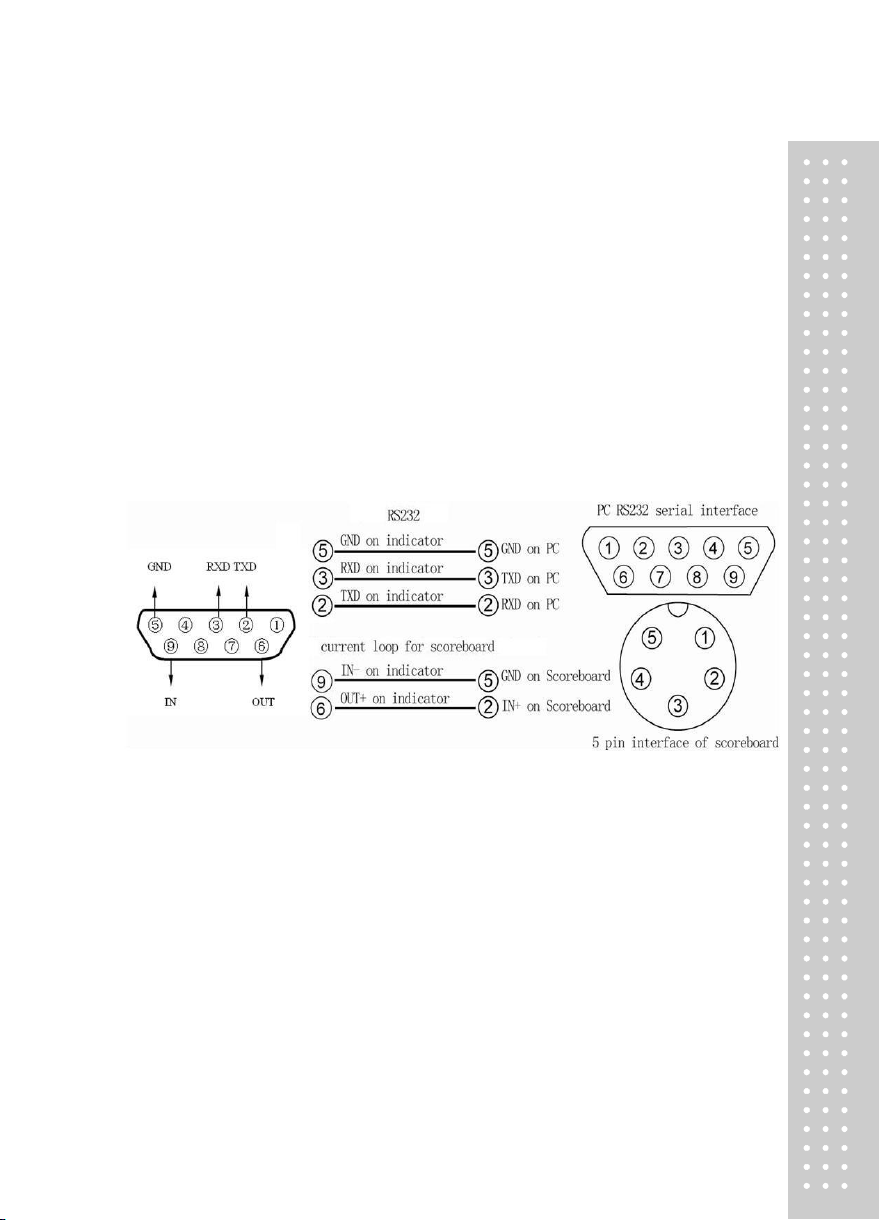

1. Serial communication

The indicator gets into self-check process after the power supply is connected. If the weight

on platform is withinthe startup zero setting range, it will enter automatic zero, and then the

weighing status. If the weight on platform exceeds thezero setting range, the indicator will

give tips and display weight.

2. key Operation

Inthecalibrationandparametersettingstatus,somekeyswillperformthefollowingfunctions:

1)[ZERO]keyperformsthe"plus1"function.Afterthe[ZERO]keyispressed,thenumberdisplayed

inthelastbitwillbe"plus1",automaticzerowillbemadeafteritisaddedto9.

2)[TARE]keyperformsthe"shift"function.AftertheTAREkeyispressed,thenumbershowninthe

lastbitwillmovetotherightforonebit,andwillmovetothehighestbitautomaticallyafterpresstare

keywhenitisinthelastbitattheright.

3)[HOLD]key performs“input” function, after the [HOLD]keyispressedthedatewillbeinputto

indicatorwhichwasset.

4)[CLEAR]keyperforms"exit"function,after[CLEAR]keyispressedtheindicatorwillexitthe

calibrationstateorsettingstate.

5)[ACCUM] keyperforms“switchingparameter"function,afterthe[ACCUM] keyispressedthe

indicatorwillcomeintothenextparametersettingstate.

3. Weighing Operation

1) ZERO :

Press [ZERO] key to enable the data within zero setting range of indicator to return to zero.

Zero setting can be performed only after the STABLE light is on.

2) TARE :

When thedisplayedweightinweighingstatusispositiveandtheSTABLElightison,pressthe

[TARE]keytodeducttheindicatedweightastareweight.Inthiscase,theindicatorwillshowanet

weightof"0"andtheNETWEIGHTlightison.Pressthe[TARE]keyagainwhengrossweightis0,

theindicatorwillclearthetareweightvalue.

Note: Tare is not workable when gross weight isnegative number.

①Inner code checking

Press [HOLD] and [ACCUM] key togetherin the normal weighing status, theindicator

willdisplaythe inner code.

②HOLD, average value :

You can choosethisfunctionbyfunctionsettingP2.Youcanstartorstopthisfunctionby[HOLD]

keyafteryourchoosethisfunction.

Choose2 for P2 parameter, press [HOLD]key, average valuelight is on, now the indicator

can estimateautomatically, and after stabilization theindicator will calculate and display

average value, and will display the average value after lighting, and also will cancel

displayaveragevalueaftercurrentvaluebacktozero,nowcanweighthenextaveragevalue;

Choose3forP2parameter,press[HOLD]keyinnormalweighingstatusandpeakvaluelightison,

andindicatornowintheautopeakvalueworkingstatus,anditcankeepthemaximumweighing

data,andwillcancelthedataholdaftertheweightbacktozero.

Inaboveoperationsteps,wecancanceltheaverageorholdfunctionbypress[HOLD]keyanytime;

andwillstartthisfunctionafterpress[HOLD]keyeverytimewhenstartup.