Introduction

as a result of regulatory updates or modifications to the

machine.

Any manual upgrades that the manufacturer may see fit to

send to users will become an integral part of the manual

and must be kept together with it.

1.5 COLLABORATION WITH USERS

The manufacturer will be pleased to provide its custom-

ers with any further information they may require and will

consider proposals for improving this manual in order to

more fully satisfy the requirements it was written for.

In case of transfer of ownership of the machine,

which must always be accompanied by the use and

maintenance manual, the original user must inform

the manufacturer of the name and address of the

new user in order to allow it to send the new user

any communications and/or updates deemed to be

indispensable.

This publication is the property of the Manufacturer

and may not be fully or partly reproduced without prior

written agreement.

1.6 MANUFACTURER

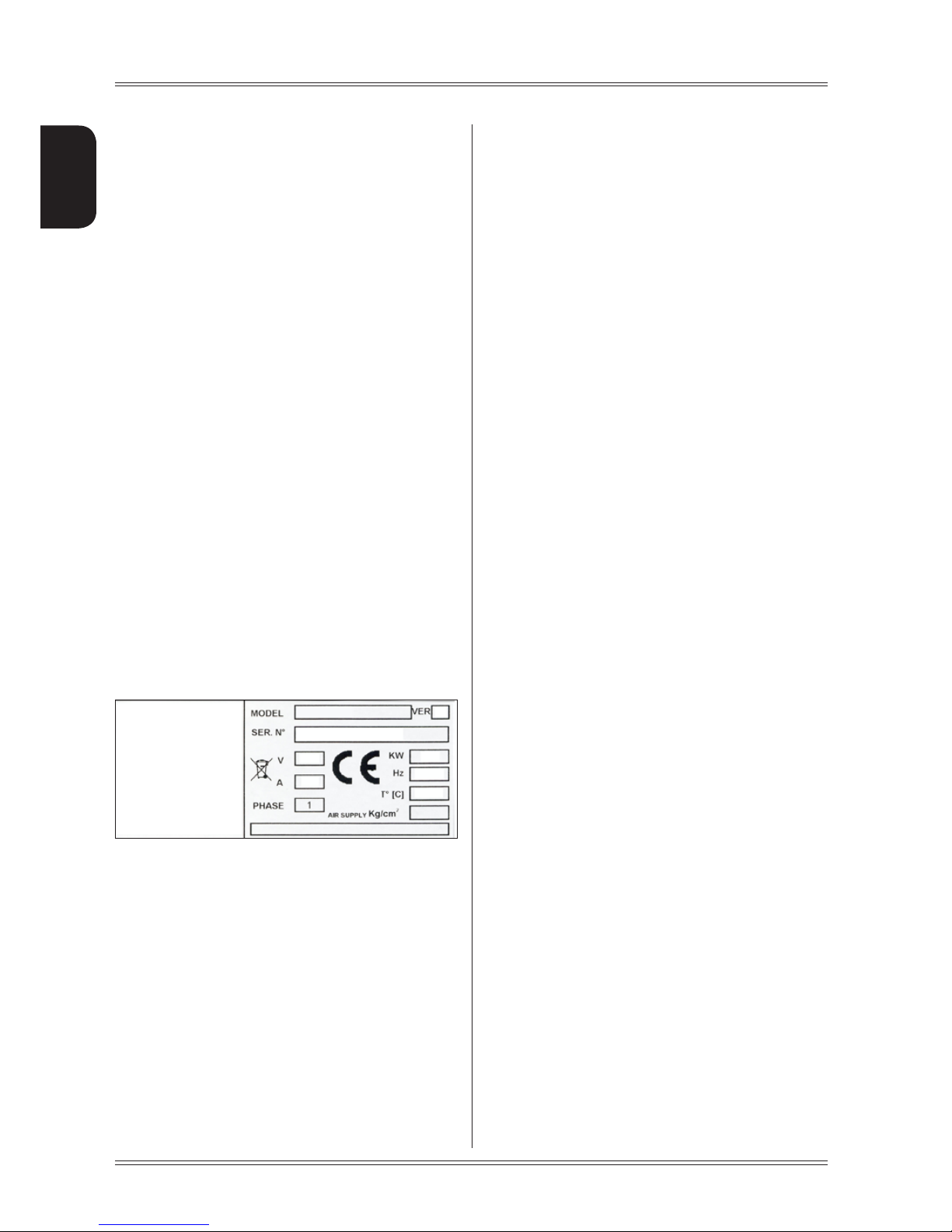

The machine identification data is indicated on the plate

mounted on the machine.

The plate below is shown for the sake of example.

1.7 MANUFACTURER'S RESPONSIBILITY

AND WARRANTY

In order to make use of the manufacturer's warranty, the

user must scrupulously observe the precautions contained

in the manual, in particular he must:

- never exceed the limits of use of the machine;

- always constantly and carefully clean and service the

machine;

- have the machine used by people of proven capacity

and attitude, adequately trained for the purpose.

The manufacturer declines all direct and indirect liability

caused by:

- use of the machine in a different way from that indicated

in this manual

- use of the machine by people who have not read and

fully understood the contents of this manual;

- use in breach of specific regulations in force in the

country of installation;

- modifications made to the machine, software and op-

erating logic, unless authorised by the manufacturer

in writing;

- unauthorised repairs;

- exceptional events.

Transfer of the machine to a third party must also include

this manual; failure to include the manual automatically

invalidates all the rights of the purchaser, including the

terms of warranty, where applicable.

If the machine is transferred to a third party in a country with

a different language from the one written in this manual,

the original user shall provide a faithful translation of this

manual in the language of country in which the machine

will operate.

1.7.1 Terms of warranty

The Manufacturer guarantees the machines it manufac-

turers against all manufacturing or assembly faults for 12

(twelve) months from the date of collection or delivery.

The Manufacturer undertakes to replace or repair any part

which it deems to be faulty free of charge at its factory,

carriage paid.

If a Manufacturer's repairman (or a person authorised by

the same) is required to work at the user's facilities, the

relative travel expenses and board and lodging shall be

charged to the user.

The free supply of parts under warranty is always subject

to the faulty part being inspected by the manufacturer (or

a person authorised by the same).

The warranty is not extended following repairs or other

work done to the machine.

The warranty does not cover damage to the machine

deriving from:

- transport;

- neglect;

- improper use and/or use not in compliance with the

instructions in the operating manual

- incorrect electrical connections.

The warranty is invalidated in case of:

- repairs made by people who were not authorised by

the manufacturer;

- modifications that were not authorised by the manu-

facturer;

- use of parts and/or equipment that were not supplied

or approved by the manufacturer;

- removal or alteration of the machine identification

plate.