Cleveland

™

Project ________________________________

Item __________________________________

Quantity _______________________________

FCSI Section ____________________________

Approval _______________________________

Date __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

STEAMCRA T®GENERATOR STYLE

HIGH SPEED CONVECTION STEAMERS

Cleveland Standard Features

I

ICooking Capacity for up to ten 12˝ x 20˝ x 21⁄2˝ deep

Cafeteria Pans, five each compartment.

IIInnovative PowerPak Gas Steam Generator: Unique

125,000 BTU, 80% efficient Vertical Atmospheric Generator

Design, only uses 75M BTU when one compartment is

used. Strong 14 Gauge Stainless Steel Construction. Large

7.5 gallon generator reservoir for high speed cooking pro-

duction. ully insulated rear mounted steam generator.

IIEasy Access Cleaning Port: Generator Cleaning Port

located on the outside, top of the unit.

IIGenerator Cleaning ight: Indicator Light located on the

front of the unit warns operator it is time to delime genera-

tor.

IIInstant Steam Stand By Mode: Hold generator at a

steaming temperature. Allows unit to start cooking instantly.

IIDurable 14 Gauge, 304 Stainless Steel Construction:

or compartment door, cavity and steam generator.

IITwo 60 Minute Electro-Mechanical Timers and Switches

for manual operation: Audible signal for cooking time

completion. (MCS)

IIMain Power On/Off Switch: Automatically fills generator

with water, then ignites gas burners via a fully automatic

Electronic Spark Ignition (pilotless) to start generator.

IIExclusive Steam Cooking Distribution System:

Exclusive Brass Steam Jets produce a high velocity

convection steam without fans. Coved Corner design in

cooking compartment distributes heat evenly, and is easy to

keep clean. Creased top & bottom enhance drainage. Cold

Water Condenser for each compartment maintains a dry

steam. ully insulated cooking compartment for thermal

efficiency. Removable Stainless Steel Slide Racks.

IIAutomatic Generator Drain: Contains a “Water Jet” Spray

Rinse Drain Cleaning Cycle to keep drain clear.

IIExclusive Automatic Probe for Water evel Control:

Separate from the generator for easy access, contains a

high velocity rinse cycle to eliminate mineral buildup.

IIExclusive “Cool to the Touch” Two-Piece Compartment

Door Design: ree floating inner door with reversible gas-

ket provides an air tight seal. Stainless Steel Slam/Latch

Door Latch mechanism for reliability.

IICondensate Drip Trough: Provide under lower

compartment door to collect condensate.

IIeft Hand Door Hinging: Compartment Doors hinged on

the left, controls on the right.

INSF Certified 6˝ Stainless Steel egs with adjustable

flanged feet for a one inch level adjustment.

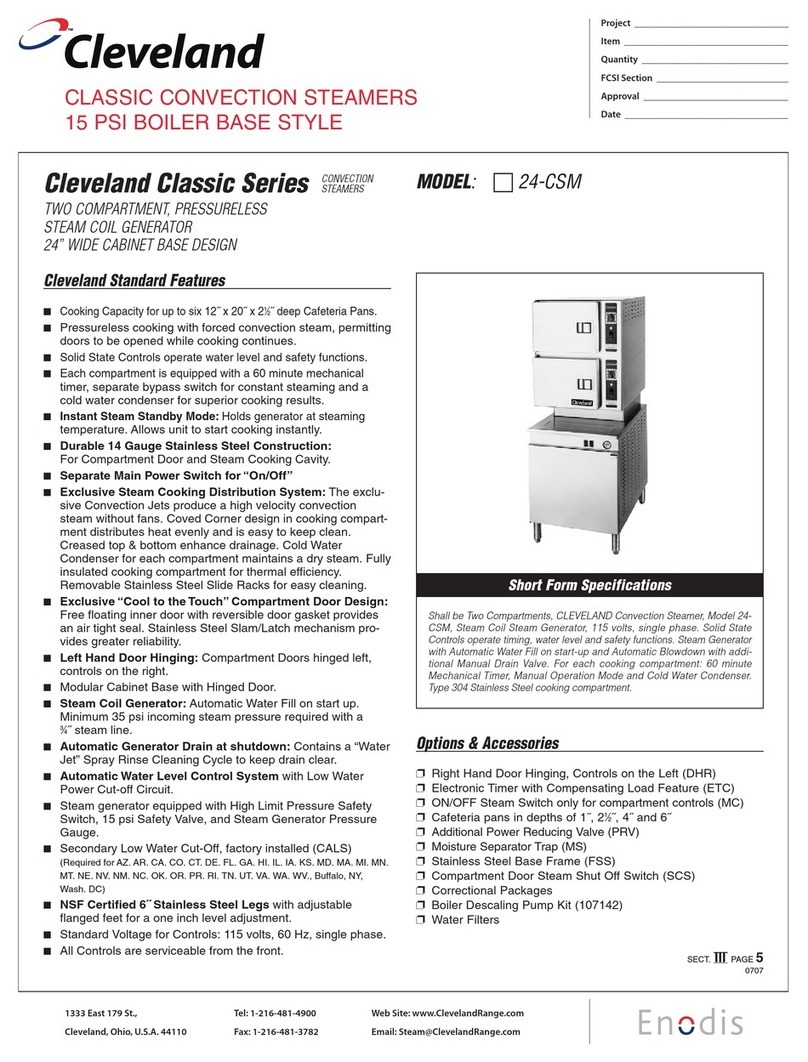

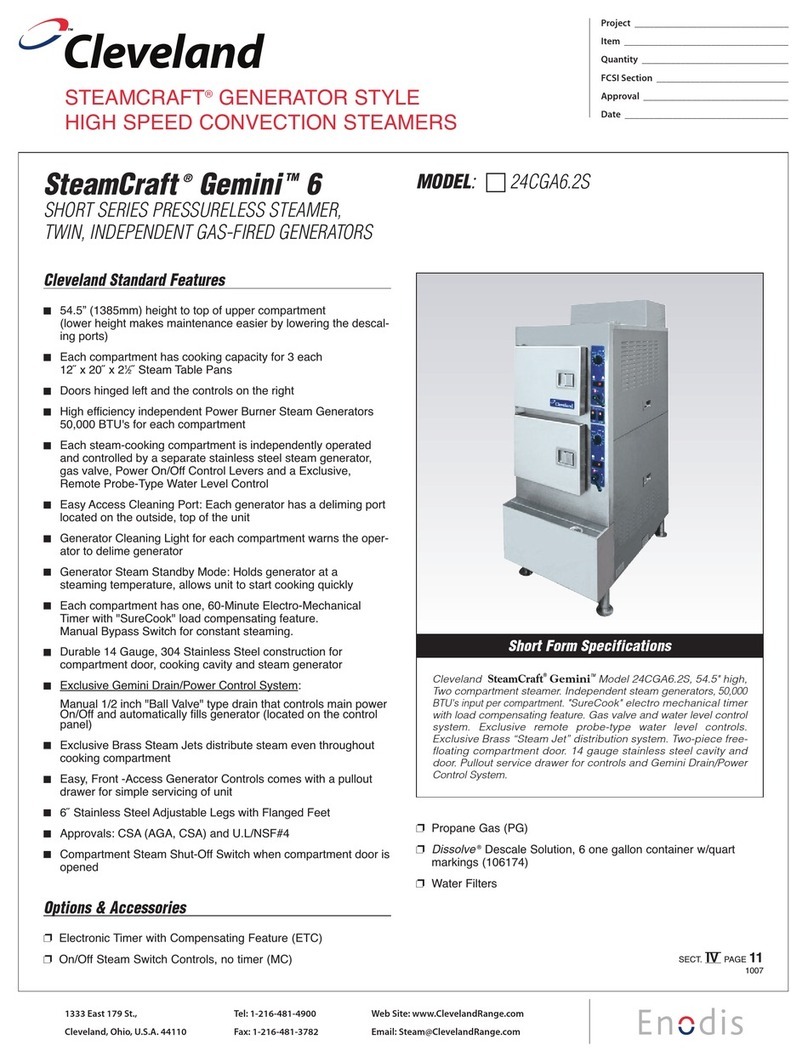

Stea Craft ®Ultra 10

TWO COMPARTMENT FLOOR MODEL DESIGN

PRESSURELESS CONVECTION STEAMER

GAS STEAM GENERATORS, 125M BTU

MODEL: 24-CGA-10

Shall be CLEVELAND, SteamCraftUltra 10, two compartments,

Floor Model Steamer, Model 24-CGA-10, sin le, lar e capacity Gas-fired

Atmospheric Steam Generator, 125M BTU input. Remote Probe Type

Water Level Controls. Steam Generator with Automatic Water Fill on start

up, Automatic Generator Blowdown, Electronic Spark I nition and

Generator Stand-by for instant steam. Choice of Compartment Controls,

Manual By Pass Operation Mode, Exclusive Cold Water Condenser

desi n, Type 430 Stainless Steel exterior and cookin compartments.

Options & Accessories

ËRight hand Door Hinging, Controls on the Right (DHR)

ËElectronic Timer with Compensating Load eature (ETC)

ËON/O Steam Switch only for compartment controls (MC)

Ë8˝ Stainless Steel Legs

ËDissolve ®liquid descaling kit. USDA and DA approved

(10617413)

ËCompartment Door Steam Shut Off Switch (SCS)

ËCafeteria Pans in depths of 1˝, 21⁄2˝ and 4˝

ËPropane Gas option (PG)

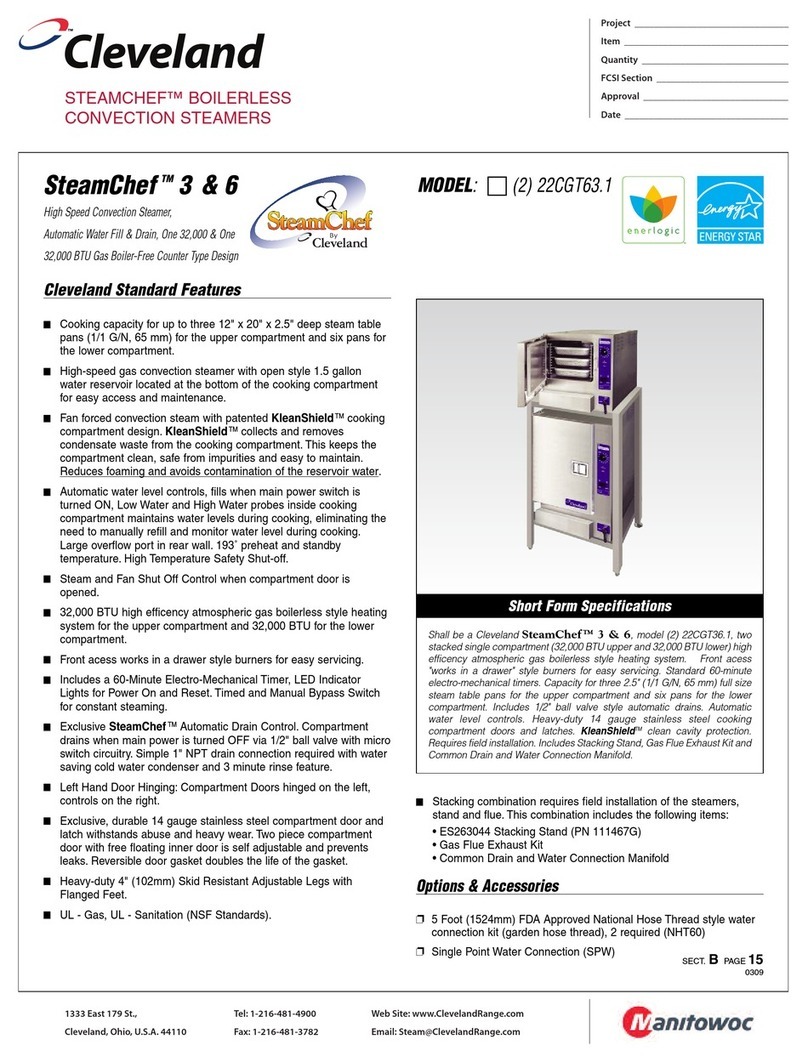

Short For Specifications

Shown with optional

Electronic Timer

SECT. IV PAGE 17

1007