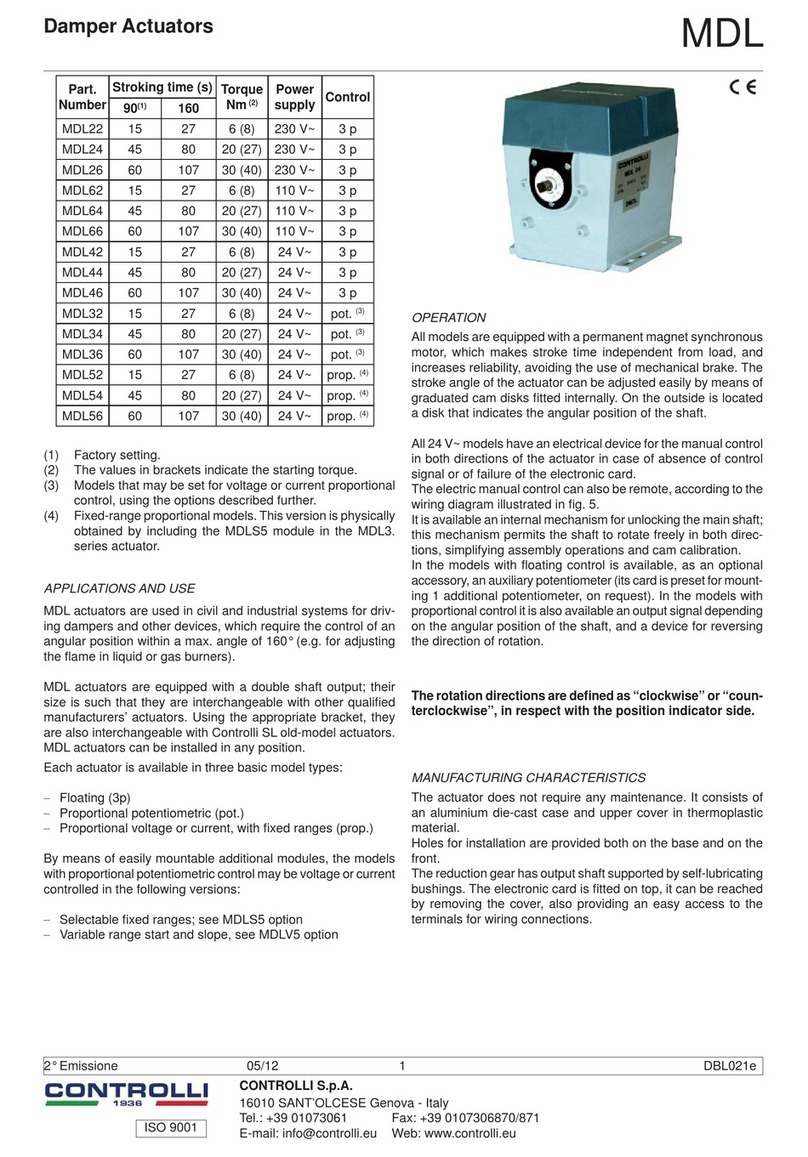

1st Issue rev. l 01/12 2 DBL021e

TECHNICAL CHARACTERISTICS

Power supply 24-110-230 V~ +10.%

Consumption 11 VA (17 VA for 230 V~)

Dimensioning 15 VA (20 VA for 230 V~)

Frequency 50 ... 60Hz

Rotation angle MDL3./5.:

preset at 90°

selectable for 160°

adjustable between 55 and 160°

MDL2./4./6.:

preset at 90°

adjustable between 0 and 160°

Stroke time Seeavailablemodels(valuesreferred

to 50Hz; if frequency is 60Hz, the

stroke time is lower than 20%)

Nominal torque See available models

Starting torque See available models

Radial force on

shaft outputs 500 N max.

Temperature

working -15T 55

storage -50T 60

Ambient humidity R class (DIN 40040)

Terminal board (*) screw-type, for 1.5 to 2.5 mm2

wires

Two cable sleeves Rubber, with membrane punchable

on D=16 mm hole; to be replaced by

PG 13.5 compression glands

Protection degree IP 55 DIN 40050 (IEC 529)

Forenvironmentwithnormalpollution

according to IEC730-1 (93)/6.5.3

Installation position any

Weight 2.6 kg

Control signal

3 position control 2 SPST contact

Proportional control

- potentiometric 165 ohm

- with MDLS5 module

in voltage 4…7V/6...9V/8...11V/0...10V

in current 4…20 mA

- with MDLV5 module

variable range start 0…15 V or mA

variable range width 3…16 V or mA

Remark: for all models:

voltage ranges 0.1 mA max

current ranges 250 ohm

Indication outputs (for MDL3./5. only)

voltage 0…10 V- (2 mA max.)

10…0 V- (2 mA max.)

current 0…200 μa

The output signal is perfectly calibrated for a 90° stroke.

For 160° stroke, a deviation of the output signal at the stroke

end (negative tolerance) may occur.

Product in compliance with EMC89/336 directive according to

the below-mentioned standards:

- EN50081-1 for emission - EN50082-1 for immunity

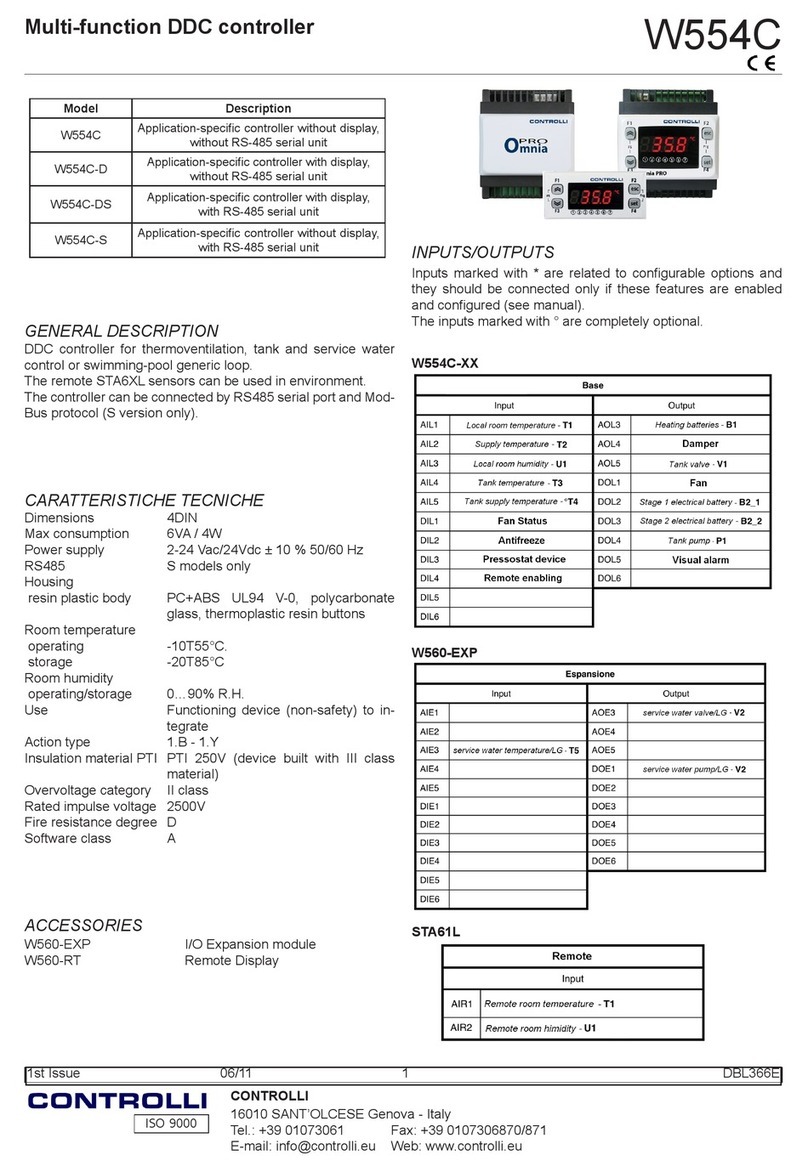

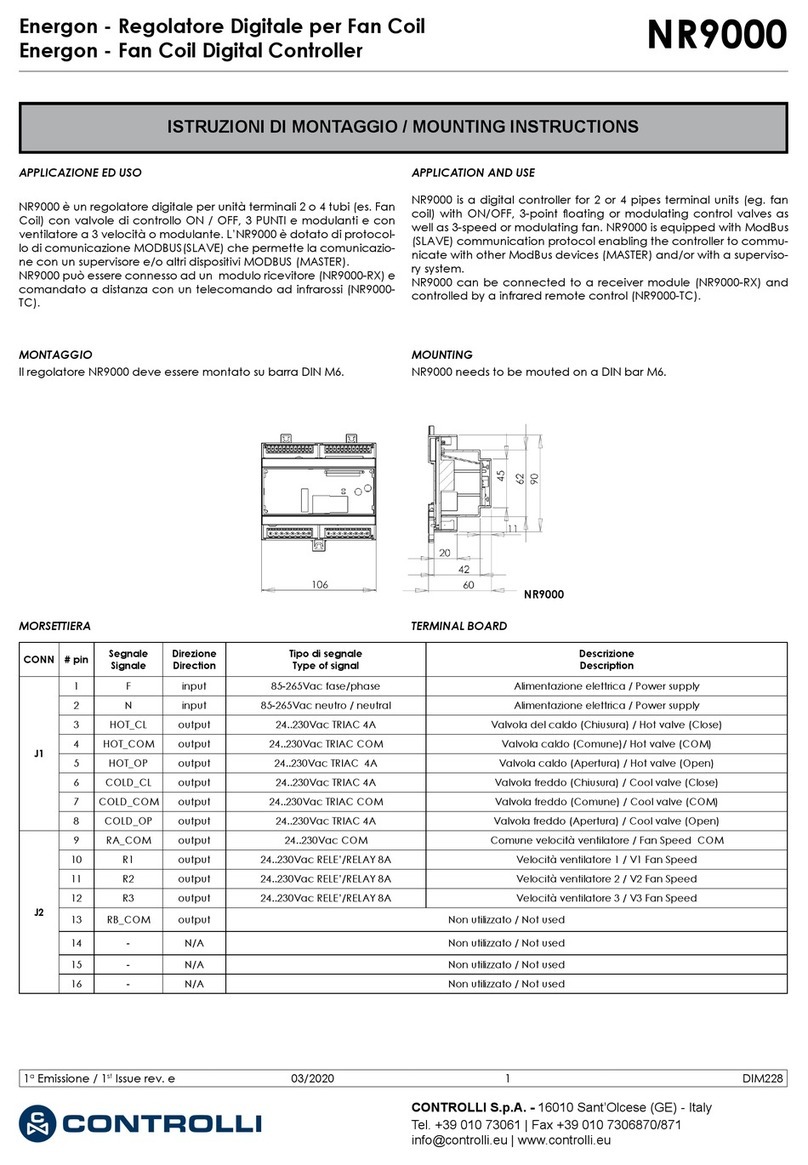

POSSIBLE COMBINATIONS AND CONNECTIONS

All actuator models can be connected to any controller hav-

ing control signal corresponding to the indications given in the

“Technical Characteristics” paragraph. In particular, they can be

connected to CONTROLLI 500 Line, DIGITROLL 4000, 7000,

Line 200 and 300 controllers.

ACCESSORIES AND OPTIONS

Model Description

DMDL Two auxiliary microswitches (SPDT 10(3)A 250 V)

adjustable on the whole stroke. Micro-disconnection

type 1B according to IEC730-1(93)/6.4.3.2

MDLA1 Damper operating lever (adjustable arm 43…74

mm)

MDLA2 Bracket for interchangeability between MDL and SL

MDLPA2 for MDL2 electronic cards with

MDLPA4 for MDL4 1 KOhm auxiliary

MDLPA6 for MDL6 potentiometer (1)

(1) On request it is possible to assemble 1 potentiometer.

MDLS5 Module for current control signal 4...20mA or volt-

age control signal, with selectable fixed ranges

4...7V/6...9V/8...11V/0...10V.

MDLV5 Module for current or voltage control signal, variable

as regards the start and the slope of the range.

YS7 Dampercontrol device (in additiontotheMDLA1 lever)

consistingof:articulatedjoints,steelconnectingrod ∅

8 mm - length 500 mm, lever for damper shaft, ∅12,

adjustable (43...74 mm).

INSTALLATION AND MOUNTING

The actuator can be installed in any position. Electrical connec-

tions are carried out by removing the cover and must conform

to existing rules.

The actuator is set for a 90° angular stroke. To set different

strokes it is necessary to adjust the cams using the supplied

spanner, inserting it into the slot near the aux. cams.

OnMDL3./5.modelsthere is a jumper to enable stroke selection

(90°/160°/VAR). Positions 90° and 160° refer to fixed strokes,

while by selecting VAR it is possible to set variable strokes (be-

tween a minimum of 55° and a maximum of 160°) using the P1

trimmer (see fig. 1).

The actuator is supplied with the shaft positioned on the 0 of the

externalpositionindicator(see fig. 2).To simplify installation and

cam calibration at the angular ends:

− using a screwdriver, unlock the main shaft, by rotating 180°

counterclockwise the loosening pivot located on the board

− put the main shaft in the desired position by operating on the

square extremity

− position the cams at due angulation

− repositionthemain shaft on 0 of the outside position indicator

and lock it by turning clockwise the pivot.

WARNING: The shaft unlocking mechanism must never

be operated under load.

On all 24 V~ models, in order to control manually the actuator,

move CM1 changeover switch to MANual position and act on

SW7 switch to control the actuator in both directions.

In the MDL3./5. models, to reverse direction in respect with

control operate on jumper SW3.

To obtain a remote manual control, besides moving the CM1

changeover switch in MAN position, it is necessary to use the

additional terminals 1, 2 and 3, carrying out the wiring accord-

ing to fig. 5. As regards the operations to be performed during

assembly, see the detailed description given in the mounting

instructions supplied in the package.

MDLS5 Option

TheMDLS5moduleispreset for 0...10 V control signal.Toselect

different ranges, move the SW1 jumper from the preset position

to the desired one (see fig. 3).

For the 4...20 mArange it is also necessary to position on SW1

the jumper set in JMP position.